Mobile HV source for on-site insulation testing on dry-type transformers

By EPR Magazine Editorial November 27, 2017 1:58 pm IST

By EPR Magazine Editorial November 27, 2017 1:58 pm IST

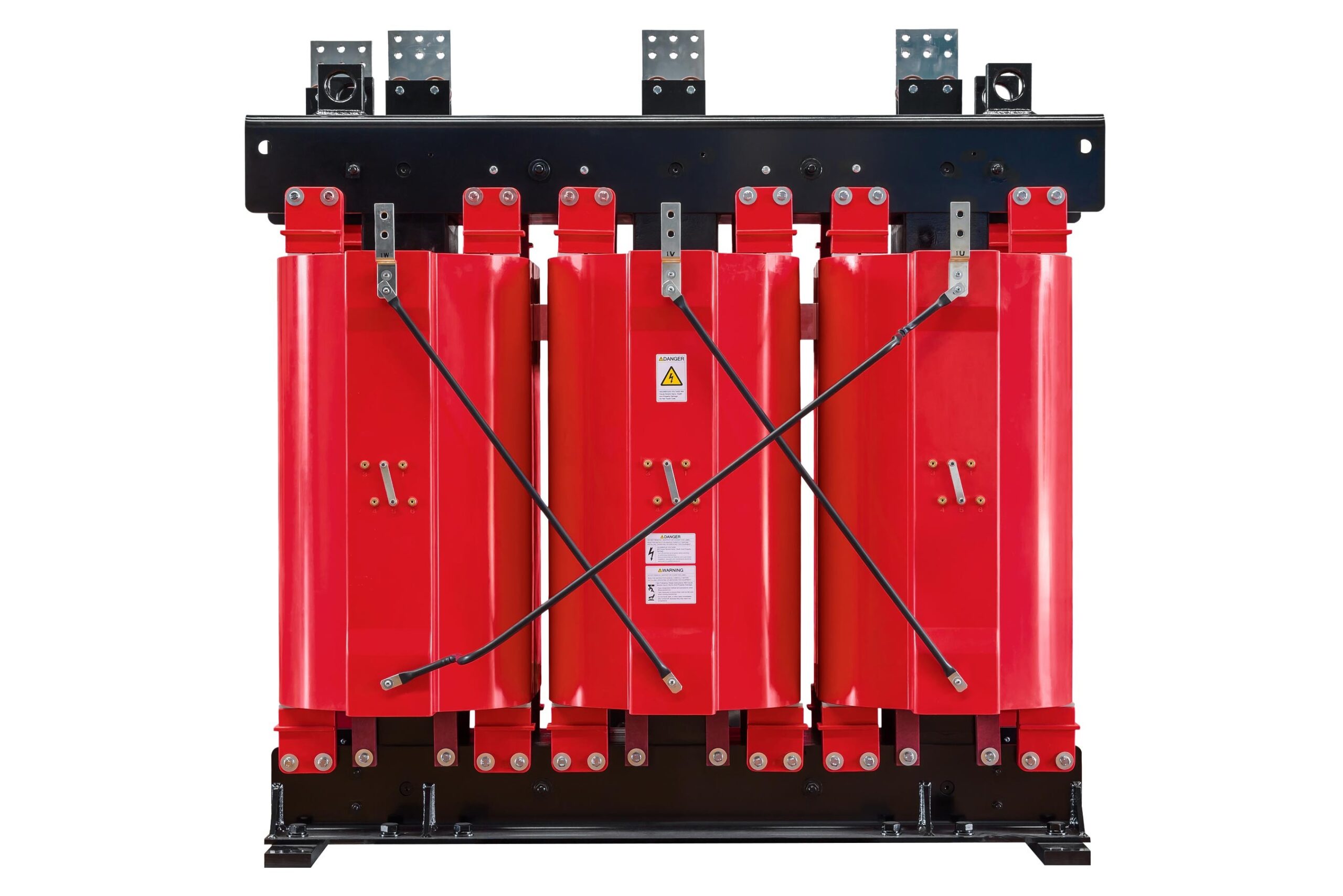

A dry-type transformer (DDT) is a safe, low maintenance and environmental-friendly solution suitable for indoor and outdoor applications where not only safe and dependable power are important. It is also compacter in size than a liquid-filled transformer, making it especially suited for hard-to-access areas or those with limited space, such as wind turbines, off-shore platforms, indoor und underground substations, industrial plants and even high-rise buildings.

Unlike in liquid-filled transformers, where the electrical core and coils are cooled with a liquid such as oil, silicone or another liquid dielectric, dry type transformers are air cooled. The dry-type transformer’s case is ventilated to allow air to flow and cool the coils.

Alternative method used for assessing insulation condition

The primary concern with all types of transformers, and also the key indicator of their life expectancy, is the condition of the transformer’s insulation system.

For dry type transformers, the insulation system consists of cast resin winding, the core insulation and the termination system insulation. The structural strength and insulating properties of materials used for these insulation systems degrade over time through normal ageing. They can also degrade prematurely as a result of overheating as well as mechanical and electrical stresses.

Dissolved Gas Analysis (DGA) is the most commonly used method for determining winding insulation condition in oil-type transformers, but is not possible for dry-type transformers.

Compared with other possible diagnostic measurements, including a dissipation/power factor measurement, partial discharge (PD) testing can most effectively detect the presence and location of PD activity and resulting insulation defects in a dry-type transformer. Analysis of the PD measurements gathered can be used as a guide regarding the condition of the insulation and for determining the need for repair or replacement before a failure and costly outage occurs. The results can be trended to chart the rate of insulation degradation between consecutive tests.

High-voltage source required for off-line tests

To determine the insulation condition of a dry type transformer, a high-voltage (HV) source is required in order to perform off-line partial discharge (PD) measurements or AC voltage withstand tests. However, such an HV source is often not conveniently available, especially for field testing. In this case, the induced voltage test can be performed as an alternative to build up the required voltage level.

The induced voltage test requires the transformer core to be energised in order to induce the test voltage on the HV side. To accomplish this, the external voltage source is connected to the low-voltage (LV) side of the transformer under test to induce the test voltage on the HV side.

A light-weight and portable HV source for on-site testing

In addition to availability issues, the traditional type of HV sources used for off-site testing are also very large, cumbersome and expensive to transport. They are also often impractical for testing in areas with limited space.

As an alternative, OMICRON’s modular and mobile CPC 100 testing system can be used as a HV source for induced voltage tests on dry-type transformers. Configurable matching transformers enable you to achieve different voltage levels on the LV side of a dry type transformer. Each matching transformer can output a maximum power of 5 kVA. This applies to a frequency range from 15 Hz to 400 Hz.

The CPC 100 unit itself only weighs 29 kg (64 lbs.) and comes in a transport case with wheels. The compact design and low weight of not only the CPC 100, but also the matching transformer makes the entire setup easy to transport and use for on-site testing in areas that are difficult to access or have limited space.

Multi-functional testing for substations and industrial plants

In addition to serving as a mobile HV source for on-site testing, the CPC 100 can also be used to perform a variety of standard and advanced diagnostic tests for commissioning and maintenance on such primary assets as power transformers, current and voltage transformers, circuit breakers and switchgear, rotating machines, grounding systems, as well as cables and transmission lines. It can thus replace several individual test devices, which also saves you time and makes it a viable economical alternative. The CPC 100 provides you with a consistent look and feel, guiding you safely through all testing procedures.

For a combined induced voltage test and PD measurement, the CPC 100 unit and a matching transformer are connected to the low-voltage (LV) side of the transformer under test to energise one winding at a time. PD activity is evaluated by recording the induced charges with the PD measurement system, such as OMICRON’s MPD 600 system, via coupling capacitors, which are connected to the transformer’s HV terminals. The end of the tested winding is grounded.

When more power is needed

As in the case of dry-type transformers, the power required to energise the test object itself can often exceed the power ratings of only one CPC 100. The number of CPC 100 devices which are needed to energise the transformer and induce the test voltage depend on the core losses and reactive power intake.

To solve this situation, the CPC 100 comes with a frequency-variable amplifier. This allows you to tune the frequency in order to bring down the reactive power intake to a minimum so that it does not interfere with PD measurements. OMICRON’s MPD 600 PD measurement system also features various advanced tools, such 3PARD (3-Phase Amplitude Relation Diagram), that effectively separate various PD sources from noise for more reliable analysis of PD activity.

A practical example

A manufacturer of dry type transformers recently received a request from a customer to conduct on-site PD testing at an indoor hydroelectric power station built into the side of a mountain.

The customer at the power station wanted a verification of the insulation condition after its dry-type transformers were put into operation for a period of time. Since a gas-in-oil analysis is not possible in these transformers, off-line PD measurement was the only other diagnostic tool most appropriate to assess the insulation state.

All of the dry-type transformers were taken out of service for the test and were energised using the CPC 100 and matching transformer as a voltage source, but the dry-type transformers were all so large that the required power to energise them exceeded the power ratings of just one CPC 100 device. To solve this, the CPC Sync function was used to create a powerful and scalable HV source.

Flexible and modular setup

Three CPC 100 units with the CPC Sync function and three matching transformers were used to excite each of the dry-type transformers. The PD measurement was then carried out phase-by-phase with a one-channel MPD 600 system.

The test setup used on site consisted of comparatively little equipment. The alternative would have been to bring a large and bulky HV source in on a truck, which would have been very difficult to bring into the indoor power plant. Instead, only the three small and transportable CPC 100 units, the matching transformers, the PD measurement system and a few PD measurement accessories were needed. It was all very easy to ship to the location, transport to the measurement site and to set up in the limited space available to work in.

Efficient testing procedure

Only two and a half days were required for setup and PD testing on all of the dry-type transformers. Before starting the test, the PD detection system had to be calibrated. Therefore, a voltage and a charge calibration were performed using the 2kV output of the CPC 100 to obtain the voltage divider factor of the PD measuring system. After everything was set up and the adjustments were made to minimise interference, the measurements could be performed quickly and efficiently.

The PD data was reviewed directly after each measurement and data streams were recorded for reporting. All of the transformers were in good condition with no noticeable PD activity.

Authored by:

Moritz Pikisch, Product Manager,

OMICRON electronics

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.