T&M: For the long life of transformers

By EPR Magazine Editorial August 10, 2018 6:22 pm IST

By EPR Magazine Editorial August 10, 2018 6:22 pm IST

An exclusive report on the need and importance of testing and maintaining the health of the transformers at regular interval.

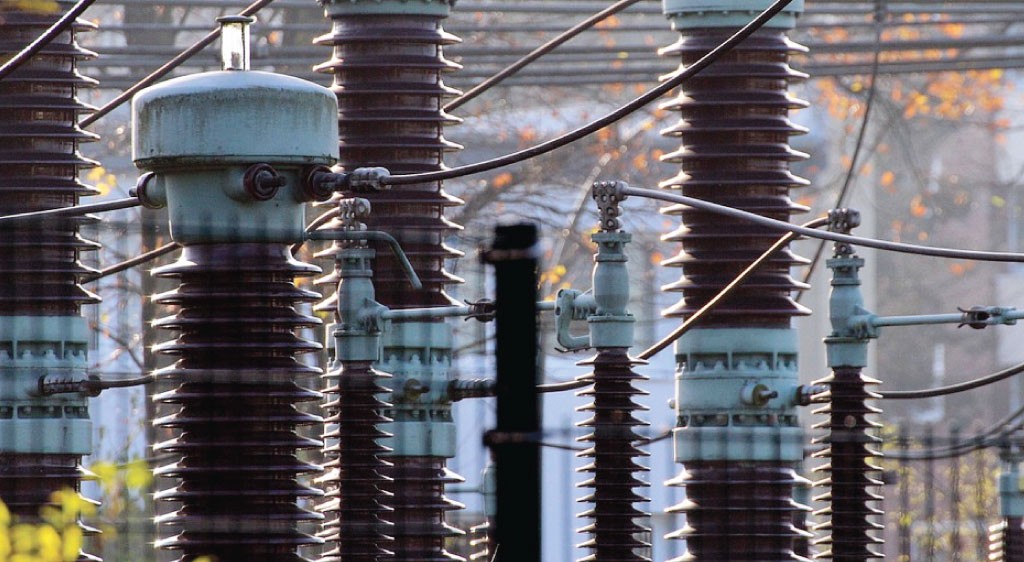

Transformer is an important electrical asset in our life which is helpful in transmitting and distributing electricity. It steps up or steps down the voltage level according to the requirement of other electrical equipment; thereby, assisting us in the smooth functionality of every kind of industries, hospitals, schools and commercial buildings. An important fact to know is the status and evolution of the transformer to be in condition so as to operate with maximum security and to know whether it is appropriate to continue its use.

Testing transformers at regular intervals

For a long time, transformers are often in operation and only cease to work when there is a maintenance task to be carried out or in case of power failure. If a transformer fails to work due to insulation failure caused by thermal stress, ageing, partial discharge, etc. it may cause blackout in the region/area to which it is supplying electricity and may stop the production/manufacturing causing revenue loss to industry or government.

Imteyaz Siddiqui, Regional Area Manager – South Asia & GCC, ISA Advance Instruments India Pvt Ltd. says, “It is better to plan predictive and preventive maintenance of transformer to keep a check on its health. If the time and causes of deterioration are diagnosed, then preventive maintenance can be done to increase its life. Therefore, it is necessary to perform various tests at regular interval to check the parameters giving an indication of the health of the transformers. “

In recent past we have seen catastrophic damages and accidents in the transformers mainly due to bushing failures. According to Parag Yelegaonkar, Business Development Manager, Testo India Pvt Ltd., “Any sort of accident in the transformer might lead to uncontrolled fire. The damage not only shuts the whole system down, but also inflicts huge monetary losses. Another aspect is the transformer radiator oil flow monitoring. At times, due to internal corrosion of the radiator tubing, the oil flow is restricted. This can cause non-uniform cooling of the transformer and can eventually lead to the transformer’s failure. Hence, there is a great need for T&M in transformer set up.”

Testing and maintenance

While operating principles of transformers remain the same, the challenges of maintaining and testing transformers have evolved along with transformer design and construction.

For Testo India Pvt ltd, the primary technique involves Tan delta testing. It is a diagnostic method of testing cables to determine the quality of insulation and life expectancy. “For this testing process, the shutdown of the power transformer is necessary in order to isolate the component for testing purpose. But if regular thermography is carried out for power transformer bushings and the thermal images are analysed, one can avoid the disastrous failures. Also, shut down of the entire transformer system is not required for thermal inspection,” says Parag.

Testo has a very good thermal imager Testo 890 of 640 X 480 pixels (with super resolution 1280 X 960 pixels) to analyse the thermal images and take corrective actions on bushing issues. Along with that a very advantageous feature of ‘site recognition’ is also available in the IR soft software of this thermal imager. “With this feature one can have a properly organised structure in software, to store and analyse the thermal images periodically. Hence, close thermal inspection of bushing with appropriate emissivity selection in thermal imager can avoid the outbreak of fire due to bushing failure. Even the non-uniform cooling of the transformer can be detected with regular thermal inspection. This is the safest way of inspection without any system shutdown,” adds Parag Yelegaonkar.

Imteyaz Siddiqui of ISA (ALTANOVA Group) says, “It is reported that if 10 per cent of transformer’s cost is spent on the condition monitoring of transformer, it will increase its life by 25 per cent or even more. Hence, condition monitoring is very important aspect with respect to maintenance and will save time and cost of replacement. The various tests include:

Latest offerings in the T&M spaceParag says, “Considering our latest and most advanced solutions for instance, our electrical instruments are very distinct and unique in their features. They are excellent instruments to inspect the electrical components and circuit failure threats.” The instruments ensure longevity and efficiency of various power electronic components that control and regulate the flow of electrical energy. The unique clamp meters and multi meters are intuitive, can measure several parameters in a single component and even have patent feature.

“Our latest solution to the industry is the new range of thermal imagers with smartphone integration designed to deliver networked thermography mostly used for predictive and preventive maintenance in electric and power sector. Wireless operation, with the ease of saving and transferring data over networks, makes our instrument more user friendly, interactive and cost effective.”

Apart from the routine tests which generally requires offline testing where the transformers are isolated from the system, these tests, on one hand, don’t require shut-down of transformers and on the other hand saves time and revenue loss during the shut-down. One of the additional advantage is that utilities are getting a bunch of the information to take corrective actions before failure of assets.

Imteyaz Siddiqui of ISA claims, “ALTANOVA Group has developed powerful and effective tools which can help asset managers to take important decisions and manage transformers in a cost-saving way. It offers a complete system and measurement chain for online condition assessment of transformers, from sensors and subsystems up to general purpose platform.”

“ALTANOVA Group is a one stop solution when it comes to the testing and maintenance of transformers. From offline PD Test to online PD monitoring along with DGA, from tan delta measurement to frequency response analysis, it provides complete solution at an affordable price and at a single platform,” concludes Imteyaz Siddiqui.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.