EV industry: Fighting to preserve the environment

By EPR Magazine Editorial July 15, 2019 2:10 pm IST

By EPR Magazine Editorial July 15, 2019 2:10 pm IST

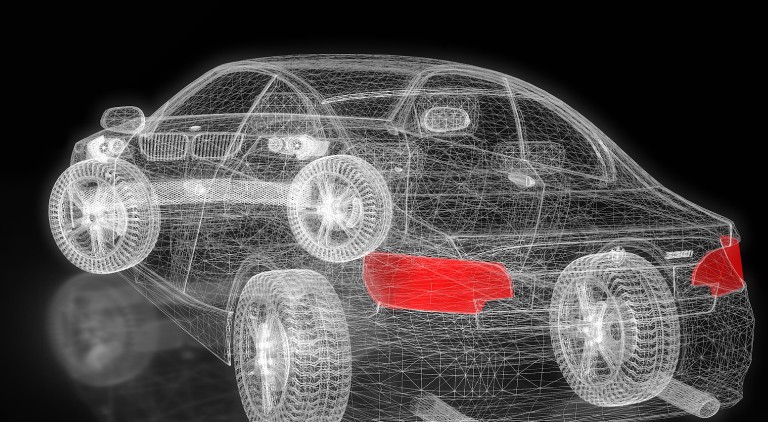

The most celebrated arrival of the automotive industry was that of electric vehicle. But, even after a grand welcome, the Indian EV industry is still struggling to find a foothold in the Indian automotive market. The industry experts share why the electric guys are struggling to be par with the conventional guys.

Many environmentally conscious Indians are willing to make the switch to electric vehicles, but the important question to ask is, “Is India ready?” The answer to this question is really simple, you don’t really need to enter rural India to understand the challenges with power supply.

Struggles of Indian EV industry; the conventional engines still holds the crown

Many of our cities too witness the load shedding on a daily basis. Power fluctuations and surges can lead to damage to essential expensive components including the battery. The battery by itself is a challenge. The regular lead acid batteries are a cheaper than the more reliable lithium ion batteries. Barun Bharadwaj, Regional Business Director (IMEA), Automotive OEM, Henkel Adhesive Technologies says, “The lithium ion batteries are expensive as they are not manufactured in India. The country still does not have the infrastructure to manufacture these. Considering that an electric car will need at least 30-40 minutes to charge to at least 80 percent, it could lead to huge queues at the charging stations. In a city like Mumbai, which has huge car congestion, with approximately 510 cars for every km, it might prove to be a huge ask in terms of infrastructure and charging stations. At present, electric vehicles are taxed at 12 per cent GST, as compared to 28 per cent plus cess for petrol, diesel and hybrid vehicles.

Bharadwaj says, “This is a strong indication of the government perspective, but has not been able to get the required traction. The key reason for this is that the cost of an EV is twice as expensive as a regular IC engine car. Currently, battery technology accounts for up to 50 percent of the cost of producing an electric car, which is why today’s models are significantly more expensive than equivalent cars with conventional engines.”

Naman Chopra, Director, CEO – RexNamo Automotive says, “The main struggle faced by the EV industry is, the battery energy density and cost. Almost all the batteries are imported and with very little indigenisation currently. One issue for Tier 3 cities and remote towns is the electricity production. So EV’s will find early adopters in the Tier 1 and 2 cities first.”

The performance of car batteries crucially depends on their operating temperature. They must remain within a constant range of 15 to 35 degrees Celsius. Bharadwaj says, “Henkel plays an important role in the integration of the battery packs. We bring our extensive automotive expertise in the field of structural adhesives and sealants to bear very early on, as we support our customers during the design phase for their cars. Henkel technology, even comes into play in power inverters, which transmit stored energy from the batteries to the electric engine.”

Owing to these factors, it is clear that the shift to electric vehicles would not happen overnight. The world is still analysing the costs and benefits of electric vehicles and India is no exception. The only way for EVs to become easy to buy and run is for the government, manufacturers and above all else, buyers to work together and create an environment where zero-emission cars are more desirable.

EV charging needs to be part of your smart mobility planningChopra says, “Till the time those EV’s become affordable/viable, we will still need charging infra at offices, public parking lots, shopping malls and so on. Most of the conventional (petrol/diesel) sedan cars sold in India are under 10 lakhs; so, building an EV which offers 250 km range for less than 10 lakhs, are the real challenge. However, once that achieved, then there is no stopping EV’s from eating away the market share from conventional cars.”

However, Bharadwaj asks. “Why just stop at EV charging?” Mobility is a given in every city; however, with increasing population that is coming to the cities there is an added burden to the infrastructure. Today, with the help of big data and analytics, an increasing focus on sustainability and reducing our carbon footprint, the need for a cleaner environment is no longer an incidental priority, but an imperative.

Having said that, we believe cars in the future will become quiet and dynamic. They will be safe and comfortable. Moreover, some vehicles will give people the option to climb in as passengers and let themselves be driven autonomously. They will also be intelligent, communicating with other cars, streets or parking spaces. This experience will be reflected inside the car as well, where the cockpit will become digital. Display innovations will make new infotainment functions possible, and revolutionize steering and operating commands. We believe smart mobility goes beyond just charging of EV’s batteries to becoming a data highway, that will utilise multiple components to make driving on the streets a breeze.

“The world is still analysing the costs and benefits of electric vehicles and India is no exception”

Barun Bharadwaj, Regional Business Director(IMEA), Automotive OEM, Henkel Adhesive Technologies

“Building an EV which offers 250 km range for less than 10 lakhs is the real challenge but when achieved, there is no stopping EV’s from eating away the market share from conventional cars.”

Naman Chopra, Director, CEO – RexNamo Automotive

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.