Only quality solar cables to work untiringly for 25 years

By EPR Magazine Editorial August 2, 2019 1:45 pm IST

By EPR Magazine Editorial August 2, 2019 1:45 pm IST

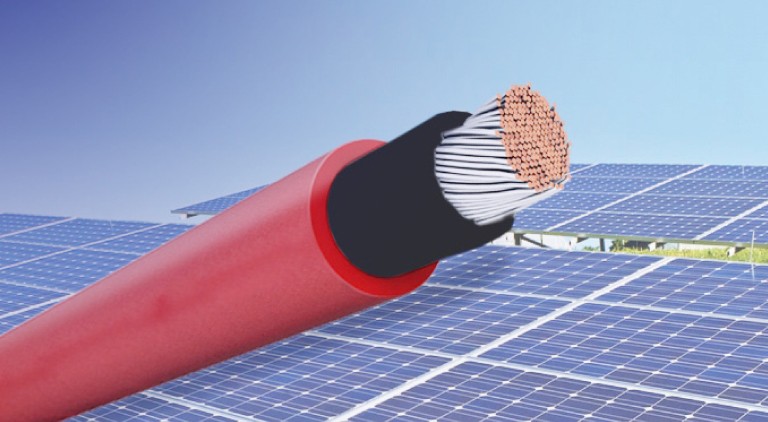

Solar cables are one of the significant aspect of the solar system, as it enables to transfer the stored energy, generated by the solar system, to the end user. The industry views where the current market stands and the quality concern when it comes to manufacturing solar cables.

Ever since India started generating and storing renewable energy, especially the solar power, to reduce the extensive consumption of fossil fuels, there has been a substantial change in the habitat of not just the commercial industries, but also among human lives. Going solar, the system needs to be hybrid, and India has not yet reached up to the required stage for going hybrid. Individual solar and grid when put together, deliver good results, and that is evident with a couple of projects undertaken by big market players.

Solar cables market in India

The market for solar cables in India is yet to achieve a considerable benchmark and fulfil the industry’s expectation. Devaraj Tigaiya, DGM-Business Development, KEI Industries Limited, says that, The industry, no doubt is growing, but the only drawback here,I think is that, the government is investing a surplus amount to boost the growth in large infrastructure and large commercial projects and commercial companies.

The market size of the solar cable by virtue of the increase in PV capacity addition has shown a good growth in the last 5 years. In terms of value, solar string cable share is,approximately, 2 lakhs per MW which is roughly 0.6 per cent of the project cost. This means a lot rides on the PV capacity addition at utility and off-grid segment year on year. Marc Jarrault, Managing Director, Lapp India Pvt Ltd, says, The other segment driving the growth is the off-grid market under RESCO & CAPEX model for industrial and commercial (I&C) customers which is dominated by major players such as Cleanmax, Amplus, Cleantech, Renew etc.

Viewing the amount of investments being made in the industrial and commercial segments, and not being enough keen in incorporating the solar advancements in the residential segments, Tigaiya has an opinion, that least efforts are carried out to reach out to the bungalows and the residential areas, where the solar cables, or solar power can be used as an alternative source. This can be a due to lack of wakefulness among people and society.

He further emphasises on the payback promises being made by the utilities, and says, The company though promise a pay back in coming 10 – 20 years, but how do one ensure the company’s existence 20 years down the line. Here, we need to make the common man aware of the bigger picture; once the subject becomes relevant to the society and the people, then it won’t be too far from having an absolute solar future.

Whereas, Jarrault has a different opinion to it, saying, Looking at industry growth, the PV capacity has grown at a CAGR of 50 per cent with the installed capacity rising from 3744 MW in 2014-15 to 28390 MW in 2018-19. Though there has been lot of design optimisation, the market still offers tremendous potential for the growth of solar cable requirement. Jarrault, feels that, there has been a reversal in this trend. He further adds that in the last 3 years, from the year from 2016-17 until 2018-19, the industry witnessed a sharp growth at a CAGR of 32 per cent. Interestingly, it was a sharp de-growth of 32 per cent in capacity addition in the fiscal year 2018-19 compared to the 73 per cent growth a year before.

Quality has been a major issue in terms of cablesJarrault, is of opinion that EN 50618: 2014 applicable for system voltage of 1500 VDC is the preferred industry standard widely in use. These cables are double insulated designed to withstand extreme climatic conditions under outdoor application. Most of the companies follow standard guidelines of FGA Germany and TUB cable among others, and doesn’t have any specific guidelines set for testing the cables, hence they end up reaching out to a foreign nation for testing and certification. Hence, Thigaya insists on having a set of standard guidelines framed either by the government, or by the official installation body, so as these products can match the certification standards. While there are several techniques including mixing raw materials possible for the manufacturing of PV cables to meet these standards requirement, Jarrault says LAPP uses superior polymer based compound which has been in use for over more than a decade and thus proven world-wide.Moreover, they are made by using superior electron beam cross-linking technology, manufactured in world class factories, with superior testing facilities. Jarrault confidently says that this enables them to meet their customer’s demand and be their preferred choice for the next 25 years.

“The important aspect, choosing the raw material, is to check whether the olefin compound and copper is sufficiently present in a solar cable.”

Devaraj Tigaiya, DGM-Business Development, KEI Industries Limited

EN 50618: 2014, applicable for system voltage of 1500VDC and the preferred industry standard, are double insulated designed to withstand extreme climatic conditions

Marc Jarrault, Managing Director, Lapp India Pvt Ltd

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.