Earthing unearthed for control panels

By EPR Magazine Editorial September 12, 2019 3:36 pm IST

By EPR Magazine Editorial September 12, 2019 3:36 pm IST

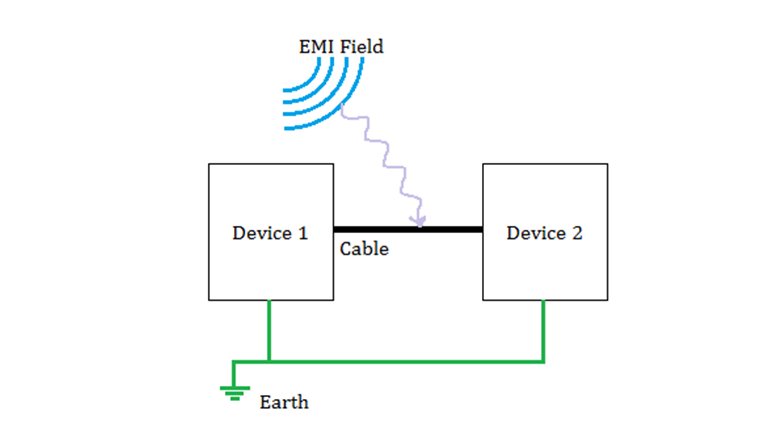

Earthing is to be performed to facilitate electromagnetic compatibility between systems and to avoid the occurrence of electrical shock to person working in the vicinity of that electrical system during ground faults.

Need for earthing

Equipment in automotive industries where control panels are situated are of high frequencies which when interfered with other electrical components cause malfunction. During faulty conditions, high current flows through the system and there is a possibility that current does not flow through its intended path instead flows through metallic body of machines or panel.

When a person comes in contact with such an electric circuit or source of electric energy, he/she is prone to an electric shock.

In order to safeguard operating personnel and system from electromagnetic interference due to high frequency components and electric shocks, it is necessary to provide a path to divert the fault current, this calls for the arrangement of earthing systems.

What is earthing?

As per IEEE 80-2000, a conducting connection, whether intentional or accidental, by which an electric circuit or equipment is connected to the Earth or to some other conducting body of relatively large extent that serves in place of the Earth is called earthing.

A safe grounding must fulfil the below mentioned objectives:

To provide means of carrying electric currents to Earth under normal and fault conditions without exceeding any operational limits or affecting service continuity.

To assure that a person in vicinity of grounded facilities is not exposed to the danger of critical electric shock.

Earthing of electrical panel

What should be measured at earthing point?

Earth resistance: A very few standards mention the exact value of ground resistance, ideally the value must be 0 ohms. Standards such as IEEE recommend a ground value of less than 5.0 ohms. The earth resistance must be measured periodically to make certain that our system is grounded properly and ensures human safety during faults, because if ground resistance is high fault currents will flow through human body when in vicinity.

Earth voltage: It is recommended that the Earth must be at zero potential. But due to neutral connection, a small amount of earth to neutral voltage is present. It must not exceed more than 2V, where 5V is the upper limit leading to circulation of ground currents.

How will you test earth resistance?

The Fall-of-Potential method is commonly used and gives accurate results than the Dead Earth method which is not so common and practised only when a quick-check is required. The Clamp-on test method is generally not recommended by experts due to its limitations. The resistance to earth through an electrode can be easily calculated by Ohm’s Law,

To measure the earth/ground resistance of a single earth electrode at “ Rod 1 ”, a current is forced to flow through Rod 1 by driving an auxiliary test probe – current probe or Rod 2 into the ground at a certain distance away from the Rod 1 electrode and connecting the Rod 2 to a current source. In this case, the ground resistance test meter is the current source which generates an alternating current. An electrical circuit is formed between Rod 1 and Rod 2 with current flowing between them in the ground. At points between Rod 1 and Rod 2 electrical potentials are created; there is a resistance path between Rod 1 and Rod 2 so a voltage will develop at points along this path due to the current. A second auxiliary test probe – potential probeor Rod 3 is driven into the ground between Rod 1 and Rod 2 to measure electrical potential (voltage). This voltage varies along the path between Rod 1 and Rod 2; maximum voltage occurs at Rod 1 and zero atRod 2. Current is measured between points 1 and 2 & voltage across point 1 & 3. If the position of Rod 3 is changed in a straight line, then different values of voltage are obtained. Using Ohm’s law one can calculate different values of earth resistance. When these values are plotted on a graph of distance versus resistance a curve is obtained, as shown in figure 5. The inferences are as follows:

Value of resistance increases gradually as Rod 3 is moved away from Rod 1 but at a certain point this resistance is almost constant (~20Ω).

Value of resistance increases sharply after a certain point where Rod 3 is near to Rod 2.

In order to achieve optimum results, the three electrodes must be well placed and the distance between earthing electrode and potential probe must be61.8 per cent of the distance between earthing electrode and current probe. This concept comes from a careful mathematical development particularly for the case of a hemispherical electrode, published by Dr.G.F.Tagg in 1964.

Dead earth method

In areas where use of ground electrode is impracticable, the 2 point or Dead earth method can be used. With this method, the resistance of 2 electrodes in series is measured by connecting P&C terminals together to reference ground electrode; and E connected to a separate all-metallic grounding point (water pipe or ground steel rods of building) as reference earth electrode, shown in Fig 6.

This is the simplest method to obtain earth resistance but not as accurate as Fall-of-potential method and should only be used as last resort.

Agam AET-23

The Agam earth tester, AET 23, a product by Rishabh Instruments, is capable of performing measurements of both earth resistance in ohms and also calculates AC earth voltage from 0-200V. Earth resistance testing can be performed across three ranges: 0-20 Ohms, 0-200 Ohms and 0-2000 Ohms. It is handy and very simple to use, it can work on both the Fall-of-potential and Dead earth method.

Authored by:

Neha Mistri

Key Accounts and Applications

Rishabh Instruments Pvt Ltd,

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.