Multiload monitoring systems for periodic inspection of system’s health

By EPR Magazine Editorial December 6, 2021 12:25 pm IST

By EPR Magazine Editorial December 6, 2021 12:25 pm IST

Multi-load monitor (MLM) eliminates the use of multiple energy meters, relays, and auxiliary supplies in any industry.

In industries and commercial complexes, load monitoring or we can say energy monitoring is the most essential factor. In industries, loads are usually motors, industrial drilling machines, automation plants, lathe machines, molding machines, testing benches, Owens, pumps, and office systems (PC, laptops, printing machines, lighting load, etc). Similarly, in commercial complex like shops, malls, loads are lights, elevators, escalators, and other electronic machines. To monitor all these different types of loads, several devices are used with multiple panels. With the current industrial scenario, electricity demand will be increasing twice as current energy demand in the future. Also, energy saving is the need of the hour. This further increases the need for conserving the use of electricity, monitoring its usage, and curtailing it accordingly.

Why multiple loads are monitored?

All loads need to be monitored continuously for keeping the system healthy, for periodic inspections, and for energy management purposes. In any of the above cases, if any load collapses it will lead to a breakdown in process and financial losses too. For example, in the process industry if any motor gets breakdown, then the manufacturing of certain product stops leading to delays in production, delivery, and other things.

All the loads are monitored by the below devices:

Panels in industries and commercial complexes contain minimum devices like Energy meters, relays, CT, & PT. The number of devices increases with the addition of loads and panels.

By this, the system gets complex. Though we are communicating the devices with a centralised network, the system gets complex and it becomes difficult to identify the fault. System complexity and use of multiple devices can be reduced by using a single device to monitor these multiple loads.

What is Multi Load Monitoring?

Multi-load monitoring is a concept in which a single device monitors more than one load. This concept was developed because industries were demanding compact devices with low-energy consumption.

Multi-load monitor (MLM) eliminates the use of multiple energy meters, relays, and auxiliary supplies in any industry. Also, this device helps to identify the health of different loads and reduces the communication period and loops, making system monitoring much more convenient and easy.

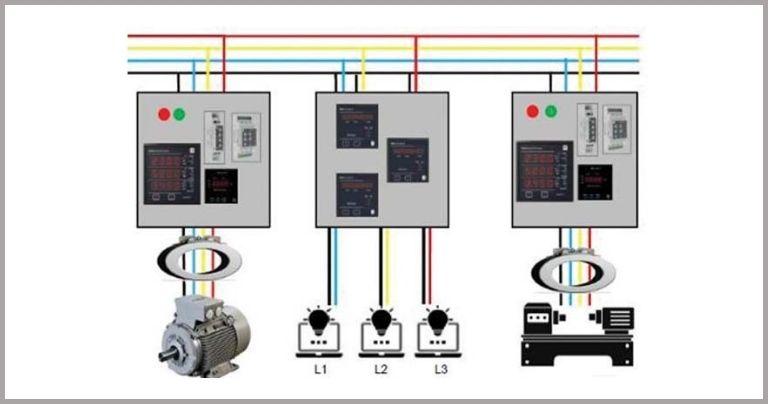

From the above figure, you can get an idea that to monitor the different loads multiple products comes into picture. It’s a meter to monitor the energy and demand parameters of a load, and relays to monitor health parameter of a load and to protect the load from any type of fault.

Rishabh’s Multi load monitor

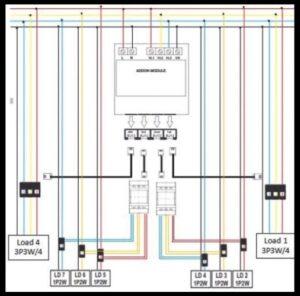

Rishabh’s comes with a solution; a meter that can monitor 4 different three-phase loads or 12 single-phase loads or a combination of three phase and single-phase loads through a single device. This device not only monitors multiple loads but also controls them using its relay outputs.

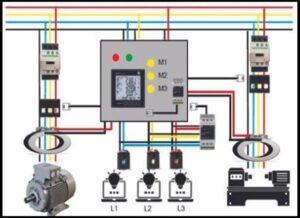

From figure 2 you can get a clear picture that a single Rishabh meter is monitoring 2 three-phase loads (motor, and lathe machine), 3 single phase loads, and also the leakage current of the connected loads. Rishabh Multi-Load Monitor “Rish ML14xx” has completely eliminated the multiple devices which were used to monitor the individual loads.

With the help of ML 14xx, system gets compact, easy to monitor, and control. ML 14xx monitors the load’s electrical parameters like Voltage, Current, Power (kW, kVAR, kVA), Power factor, Phase angle, System as well as phase wise load bi-directional Energy’s (kWh, kVARh, kVA ), Demand (current, power), Individual Harmonics up to 31st of voltage and current, THD, Min/Max parameters with high accuracy of 0.5s Class. QuickFix modules are used to connect conventional 1A/5A CT or CBCT with ML14xx.

ML 14xx not only measures the electrical parameters but also measures the residual current (leakage current) of the system with its RCM (Residual current monitoring) feature. Leakage current in any system is an important thing to monitor and control. In ML 14xx users can monitor the different loads along with the leakage current of those and can operate the relay contacts to prevent the system from any type of fault.

Also, important 3 phase load health parameters like over current, over/under voltage, under frequency, voltage and current unbalance, phase failure, and phase reversal are monitored. So, if any of the above conditions occurs in the system, the meter will operate its relay contact to protect the load. Also, it will indicate the type of fault on its screen. User, wire-man, or operator can easily check the status of each load by using a single meter. This is how a single ML 14xx reduces the system complexity and makes the work of a maintenance person easy.

Energy-saving with ML 14xx

Energy consumption of the system due to the use of multiple devices can be reduced to 20% by using Rish ML 14xx. Multiple devices use conventional CTs to monitor the current of the system and also need separate voltage and auxiliary supply to power up the meter. Considering figure.1, in this case 5 energy meters, 6 digital relays need separate auxiliary supply to power up. Each device will need two wires to route the auxiliary connection leading to energy consumption along with energy loss as the supply will flow through copper wires leading to I2R loses through it.

Now consider figure 2. for a similar case a single device is used which eliminates the need for 11 Auxiliary supplies. Also, a single threephase voltage connection is required so eliminating the extra voltage connection of 4 three-phase meters. Rishabh Multiload monitor accepts 100mA current inputs through its RJ12 port. Conventional CTs come with 1A/5A output whereas ML 14xx comes with 3 phases RJ12 CTs. These CT’s comes with an output of 100mA and with a lower VA of 0.25. This combination of low VA and low current output reduces the I2R loss caused by high current (1A/5A) flowing through the copper cables. Also, the RJ12 connection eliminates the CT reverse connection error and the CT connection time. This makes installation much faster, easier, and error free.

Applications and features of ML 14xx

Below are some of the applications of ML 14xx:

Below are some of the important features of ML 14xx:

Conclusion

So, from above it is clear that multi- load monitoring is the future of load monitoring. And Rishabh multiload monitor ML 14xx is one of the futuristic devices to monitor the different loads with its unique features. That is, Load monitoring with system transparency with a blue impact of energy saving.

(This article is authored by Mst. Rahul Pansare, Business PromoterDigital, Rishabh Instruments Pvt. Ltd)

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.