Thermal imaging technology to improve operations of photovoltaic power stations

By EPR Magazine Editorial July 30, 2022 12:03 pm IST

By EPR Magazine Editorial July 30, 2022 12:03 pm IST

Power equipment inspection is a critical operation to ensure power equipment safety, reliability, and low failure rate.

How does thermal imaging technology enable the better operation of photovoltaic power stations?

Photovoltaic modules are devices that absorb sunlight. It then directly or indirectly converts solar radiation energy into electrical energy through the photoelectric effect or the photochemical effect. As the new energy industry leaps forward, photovoltaic power stations have become an indispensable part of the new energy power generation sector. With the expansion of photovoltaic power station scales, the diversification of photovoltaic power station modes, and the development of distributed photovoltaic power stations, the operation and after-sales service of photovoltaic power stations have become increasingly important. In particular, the emergence of household photovoltaic power stations calls for more effective photovoltaic operation and maintenance. The huge installed capacity of photovoltaic power stations increases the probability of photovoltaic power station failures, resulting in increased safety hazards. Featuring strong penetration, immunity to strong light interference, low power consumption, and long service life, thermal cameras can operate from afar under all weather conditions.

Thermal imaging technology is capable of identifying concealed targets and enables photovoltaic power station operation and maintenance personnel to detect them more efficiently and conveniently.

Thermal Imaging Applications

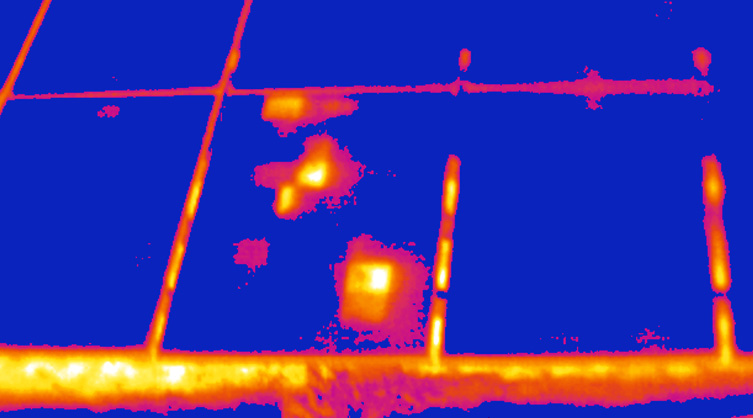

Solar Hot Spot Detection Solar hot spots can cause severe damage to solar cell modules or systems. Therefore, it is necessary to perform hot spot detection on solar cell modules so that cells generating relatively uniform heat are combined or maintained to prevent the energy generated by the modules from being consumed by modules with hot spots. In addition, the possible impairment brought by hot spots, which may shorten the service life of solar modules or systems, can be avoided. Thermal imaging converts invisible infrared radiation into visible temperature distribution images that reflect the thermal distribution on the surface of items to clearly visualise the temperature difference on the solar panel for quick location of fault points.

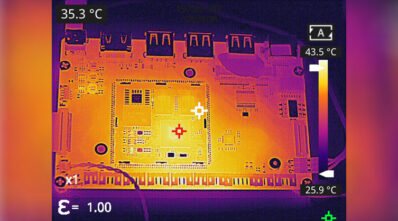

Solar inverter circuit board inspection

Electronic circuit failures generally involve short circuits, open circuits, and poor contact. The infrared emitted by a circuit under normal operations is different from that emitted through faulty electronic components. In the case of a short circuit, the current is larger, and the components are hotter, emitting more infrared radiation. At this point, it is quite different from a normal situation in thermal imaging. In the case of an open circuit or poor contact, the current flowing through components is almost zero, so the temperature of components is lower than that in normal operation in thermal imaging, and there is nearly no infrared radiation. At this point, the thermal image is quite different from that of a normal situation. By analysing the thermal imaging heat map, engineers get to know the temperature distribution of the entire circuit board and can optimise the design and application of the circuit board accordingly.

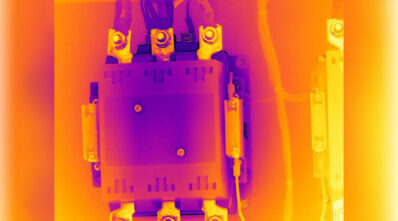

Electrical distribution cabinet monitoring of solar power generation systems

Prolonged exposure of electrical contacts to high temperatures can cause insulation degradation or fire. Inspection of power equipment is a fundamental operation to guarantee the safety of power equipment, improve the reliability of power equipment, and ensure that the power equipment runs with a low failure rate. Thermal cameras can visualise hot spots and their temperatures clearly and support coordinated image capture in the case of abnormal temperatures for cause analysis and timely treatment.

During the operation of solar energy systems, defects in battery modules are the most frequently encountered. Such defects are shown as the “hot spot effect” in thermal imaging. Defective modules cannot convert the thermal energy absorbed into electricity so that they are directly shown as “high heat”.

Thermal cameras can agilely and accurately capture the minute temperature changes on the surface of the item to be measured, and enable contactless detection of solar cells or module defects. The location of product defects is accurately visualised in thermal imaging, making it a convenient and fast detection solution for operation and maintenance personnel. Safety monitoring system for energy storage stations Thermal cameras can monitor the temperature distribution inside a container round-the-clock in real-time and adjust the air outlet orientation of the cooling system or air conditioner so that the container’s temperature is intelligently controlled. They support the coordinated operation of the fire-fighting systems and can capture images, record videos, or set off on-site alarms and fire-fighting devices in the event of an abnormal temperature. They also support real-time storage of visible light and infrared videos to help accident retrospect and determination of temperature rise points at a later stage.

Perimeter protection for photovoltaic power stations

Most photovoltaic power stations are built in unattended open areas. Thermal cameras can expose suspicious individuals approaching the energy storage station day or night. When the monitoring area is trespassed by unauthorised individuals or vehicles, the infrared device can set off alarms in time, promoting the staff’s intervention

The advantages of thermal cameras:

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.