The demand for AI and IoT in the T&M sector is trending

By EPR Magazine Editorial November 25, 2022 11:54 am IST

By EPR Magazine Editorial November 25, 2022 11:54 am IST

The global energy sector is undergoing rapid changes, particularly in the area of new energy, where there is an increase in the use of solar, wind (including offshore wind), and energy storage, which has a substantial impact on the need for new and increased testing equipment.

Emerging Trends

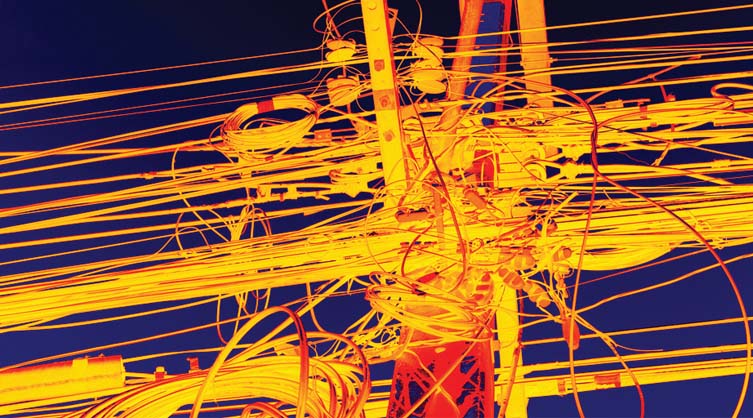

Globally, fossil fuels are practically the only source of power. The world is looking for strategies to reduce dependence on natural assets. Therefore, alternative energy sources, including solar, wind, and micro- and smallscale hydro projects, are given increased attention. With that, more areas and influential organisations are adopting the method of unattended operation and intelligent early warning due to intelligentisation and IoT-based development. “Thermal cameras, frequently used instruments for rapid visual troubleshooting can significantly increase the efficiency of routine inspection and troubleshooting compared handheld metres,” says Aaroy Yu, Product Manager IRay.

Prabhakaran PV, Head of Product Management, Fluke India, says, “There is a need for advanced monitoring and control systems that may be utilised to manage and supervise massive power networks. The increasing usage of artificial intelligence (AI) in T&M solutions is a trend. EVs and chargers are dealing with weaker generation systems as more and more nonlinear generational methods are implemented. With such generation, distribution, and a smart grid in place, it is vital to check and improve the system’s dependability, necessitating more T&M technologies.

While highlighting the latest trends, Kalidas Bhangare, Managing Director, Testo India Pvt. Ltd. says, “Plans may show a subtle movement from power generation to supply, or from distribution, if we concentrate on the power sector. India will now experience a noticeable shift towards efficient supply and an optimal generation mix primarily consisting of solar, hydro, and nuclear power. This is due to our country’s surplus of thermal power generation capacity, with moderate demand and a growing share of renewable energy. It will technically increase the market for electrical assets such as cables, transformers, transmission lines, switch yards, and storage, which has been growing linearly.

In addition, smart measurement techniques would be widely used, and all relevant parameters would be maintained and tested routinely. From the utility perspective, we play a significant role in assisting power utilities to improve efficiencies by maintaining asset availability at the highest possible level and minimising losses. Our tools, such as thermo-vision cameras, electrical instruments, and data loggers, are utilised in climate monitoring and in predictive and preventative maintenance on the primary electrical equipment described above.

Challenges

Energy efficiency should be considered from product conception to product implementation. Any electricity company’s biggest worries are unplanned outages and downtime. It will be easier to prevent unneeded downtime if a system is properly built.

One of the main challenges in the T&M sector is appropriate troubleshooting and detecting the problem with predictive methods. Moreover, the main difficulties include:

• Overloading and low voltage in power transformation and distribution systems.

• Tripping due to line faults.

• Difficulty locating fault spots promptly

According to Bhangra, “the probability of a system failure rises with incorrect system testing and measurement. Unidentified flaws can result in significant energy and financial losses. To mitigate such critical losses, the facility manager or system engineer must exercise special caution while implementing proper electricity industry maintenance procedures.”

While discussing the challenges, Prabhakaran states that “developing essential metrics, appropriate instrumentation, condition-based monitoring, trends of equipment health, and thermal profiles of assets will aid engineers in making the best decisions before a failure occurs. To avoid the downtime for identifying and rectifying the issues and resolve the system.” However, the downtime can be greatly reduced if it is monitored with planned shutdowns. This further demonstrates that the major problem one might face in sustaining grid stability is the need for better best practices and cutting corners to lessen initial costs.

According to Yu, the main difficulties are overloading and low voltage of power transformation and distribution systems, tripping due to line faults, and difficulty finding fault spots promptly. He also states, “Live detection is made possible by thermographic technology, which is also very useful for fault pre-check, maintenance, troubleshooting, monitoring, and other activities during power grid inspection and maintenance.”

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.