Boosting power system reliability with surge arrestors in high-ground flash density areas

By EPR Magazine Editorial November 6, 2023 5:52 pm IST

By EPR Magazine Editorial November 6, 2023 5:52 pm IST

Lightning is a natural & very dynamic phenomenon in which a shockwave hits a place or an object on earth causing potential damage.

The shockwaves are very high-voltage impulses that try to find a short path to reach the ground,during lightening the lightning current of high frequency current passes to different earth connected paths and results high potential . In this process, these shockwaves land on a taller and more conductive material causing it to face severe damage. Lightning is a marvelous show of nature and its very dynamic natural phenomenon, due Lightning many fatal electrical accidents takes place worldwide. The major impact of lightning on transmission & distribution lines are reducing the reliability by causing the non-schedule outages like Insulator Flashover (Back flashover). Overhead transmission lines are most prone to lightning strokes. Lightning induced voltages reaching the tower and causing the line insulator to flashover results in major interruption. Due to the lightning, discharge current flowing through the tower due to back flashover results in potential difference across the line insulator in view of tower footing resistance. A very nominal interruption has potential to result in heavy revenue loss to power utilities. To mitigate /minimise the Lightening (Thunderstorm) impact on transmission lines we can use of transmission line surge arrestors to minimize the lightning related tripping’s/Flashover by Installation of Transmission Line Arrestors (TLA) in Lightening prone area and high ground flash density area. This article explains how installation of line arresters has served not only to protect insulator assemblies from flashover due to lightning but also improved safety as well as quality of electricity on overhead lines.

INTRODUCTION: –

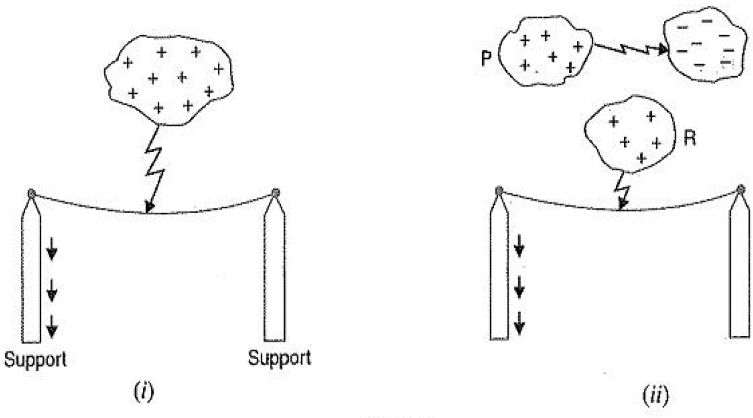

Lightning is a multi component event called flash, The single transfer of current to ground is called stroke. Lightning occurs when regions of excess positive and negative charge develop within the cloud. Overhead transmission & Distribution lines are the most vulnerable for lightning strokes, More than 50 percent of the electrical faults of overhead lines are known to be caused by Lightning .The Electrical power system is a network of electrical components used to supply, transfer and use of electrical power. Over voltage is one of the event occurring in the power system and broadly classified into temporary over voltages, switching overvoltage’s and Lightning over voltages. Line surge arrestor is safety protective device for limiting surge voltages on Transmission & distribution lines/equipment’s by diverting surge current and returning the device to its original status and is able to repeat these function as specified Surge Arresters are the primary protection to make the circuit devices immune to different types of over voltages. The Condition of tower footing earthing plays a paramount role in performance of transmission line during lightnings. It is worth mentioning that application of TLA nullifies any impact of higher tower footing resistance. In Substation end also the Lightning arrestors are installed as well as a Lightning masts all the corners of Substation for protection against the lightning, In addition to above now lightening arrestors is also used in the transmission lines to mitigate lightning and surge related tripping’s to maintain the reliability .TLSA impedance is extremely high under normal line voltage conditions and only a small amount of capacitive current will flow through an arrester under normal conditions. When the voltage across an arrester is increased to 50 percent above nominal ,the arrestor impedance quickly drops to a very low impedance value and large resistive current through the arrester. During the conduction process the arrestor may absorb many kilojoules of energy that must be dissipated through the arrestor housing as excess heat. Once the surge has passed the arrestor returns to its original state ,and the system survives the event without disruption.

Types of Lightning Strikes :-

Direct Lightning Stroke

Lightning strike coming directly from sky and directly striking a person or object/tower due to charged cloud comes in contact with another cloud. A direct lightning strike is one in which an object/Tower or person is part of the flash channel. A direct hit occurs when all of the lightning’s energy is directed through the body or over the body on the skin or any object.

Indirect Stroke

When lightning strikes indirectly when lightning strikes an object directly and jumps the air to strike the another object, it is called Side Flash (Indirect Strike).A side flash indirect strike occurs when lightning strikes a taller object and the current jumps from the taller object into a nearby person or object.

This happens when lightning strikes an object that seeks a path that lets it jump through the air to a second object.

Ground Current – Indirect Strike

Ground current or “step potential” is a type of indirect lightning strike whereby an object or person is struck by the discharge occurring in and along the ground surface from a nearby lightning strike.

The first way is through a ground current. These occur when lightning strikes an object or the ground and the electricity travels through the ground until it encounters another object.

To measure to reduce the tripping’s of Lightning prone area: –

i) Providing additional earthing of towers through PG clamp with separate earth pit & additional counterpoise.

ii)Providing spike on tower top to capture lightning strikes.

iii) Providing one more additional insulator disc to protect against Back flashover.

iv)Providing chemical earthing like bentonite slurry earthing & Morolite earthing.

v) Maintenance free Marcionite earthing (Pollution free earthing).

vi) Bore type earthing with 100 feet depth with the use of Charcoal and salt.

Besides , Due to dry, coalfields, rocky terrain, acidic nature of soil ,High ground flash density area, condition of the Tower footing impedance could not be improved by repeated efforts on improving the TFR value ,In this situation the Installation of the TLSA in strategic location is one of the better option to minimize the tripping’s of Lightning prone area where TFR is above 50 ohms.

Advantage of TLA installations: –

Increasing the system reliability by minimizing the Lightning related tripping’s.

Lightning performance improvement and act as a safety device.

Extended protection of Substations.

Improved outage performance of existing shielded and unshielded lines which is accomplished by greatly reducing the frequency of line insulation flashover due to shielding failure and back flashover.

TLSA reduce the BIL (Basic Insulation Level) of the substation equipment’s e.g power transformer as the lightning surges are suppressed in the line itself by the line arrestors,Hence,the no of surges experienced by the substation arrestors would be reduced and hence the reliability of the entire system

Touch and step Voltage reduction due to power frequency earth potential rise

TLSA can improve the performance of lines with high ground resistance which is often of the main cause of back flashover on line protected with Shield wires.

Protective Device limiting overvoltage’s and act as a safety device.

The TLSA is especially beneficial for very tall structure with long spans like river crossing spans the tripping due to lightning is not affordable in such spans to TLSA installation gives the additional protection.Transmsiion lines is most vital component of power system.

Easy to transport and install even in difficult terrain, with Hot line also or to take Shut down.

TLSA can reduce the right of way, Transmission line losses can be reduced by replacement of Shield wire with TLSA.

The analysis all important parameter required before Installation of TLSA: –

i)Line operating maximum voltage, Ckts, Ground wire data, span length, sag of line, conductor type,Systeam grounding practice.Length of line.

ii) Tower surge impedances and footing resistance, soil impedance, arcing distance, connection length, tripping History data &Disturbance Recorder ( DR) data indicating Lightening Fault.

iii)The data sheet of flashover mark observation on the hardware and insulators & Fault Current.

iv) System studies of the power system on ATP & EMTP need to been carried out for exact tower location.

vi)During post fault patrolling observation and discussion with local villagers confirming the tripping’s have occurred during lightning and thunderstorm.

vii)TLA can be installed on all the 3 phases will be the good option but installation of the TLA on each phases is having much more financial implication. The no. & configuration for installation of TLSA may be TLSA can be installed only on top phase or in top and bottom phase only which can be selected a judiciously because the TLA installation as Installation of TLSA is very costly affaire.

Working and Construction of TLSA : –

There are basic two technologies for line arresters Non-gapped (NGLAs) and externally-gapped LA (EGLAs) – defined in IEC standard 60099-8. NGLAs are similar to substation arresters, both in design and operation. Non gapped type arrestors are used by most of the utilities. Non gapped line arresters are suitable for all system voltages and for protection against both lightning and switching related phenomena.

Again the Surge arrestors are classified as Class-1,Class-2,Class-3,Class-4,Class-4,Class-5

Surge Arrestors is classified as DL,DM,DH,SL,SM,SH.

For 400 Kv TLA Class -2(4kj/kV) and SL-Low station duty is generally used.

When lightning strike occurs in the peak of the tower, part of the lightning current flows through the ground wire to the adjacent tower and the other part of the lightning current flows into the earth through the tower. Back flashover occurs during the lightning discharge current, flowing through the tower and due to tower footing impedance producing potential differences across the line insulator. Back flashover is most prevalent when tower footing impedance is high

Zinc Oxide varistor is the main component of TLSA.The elements exhibit high non-linear voltage current characteristics. During normal voltages lightning arresters does not conduct and acts as an insulator drawing a very little leakage current. When a surge wave traveling along the overhead line comes to the arrester, the surges are absorbed by Zinc oxide elements regain its impedance (i.e., pre-breakdown condition) and ready for subsequent surge suppression.

When there is a normal voltage, the potential barrier at the boundaries of grains of ZnO does not allow the current to flow through it. But, when an over-voltage occurs, the potential barrier collapse, and a sharp surge takes place. As a result, the current starts flowing and the surge is diverted to the earth. Once, the surge collapse, the voltage across the ZnO diverters reduces and thus the current to a negligible value, ideally zero. In this way, a metal oxide surge arrester protects the power system from over-voltage surges.

However, due to high iso-koranic level at some of the tower locations, tripping of lines during lightning could not be completely reduced. TLAs are installed on the conductors, electrically in parallel to insulator strings. TLAs does not operate during normal condition. During lightning these TLAs conduct due to presence of high frequency impulse, pass on the surge to the ground safety without affecting the transmission line. In the event of lightning, instead of back flash over across insulator string, TLA conducts and provide path to the lightning current towards phase conductors. It not only avoids flashover but prevents tripping in the transmission line. It is worth mentioning that application of TLA nullifies any impact of higher tower footing resistance.

TLSA Composed of Zinc Oxide, become conductive when exposed to high voltage and behaves as an insulating medium during normal conditions thus protecting the insulators (from flashover) and conductors (from degradation) of the system from the damaging effects of lightning without any outage of the system. The disposal of the TLSA after its age, Overloading or any breakdown proper care should be maintained.

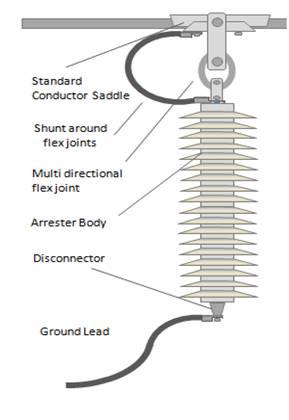

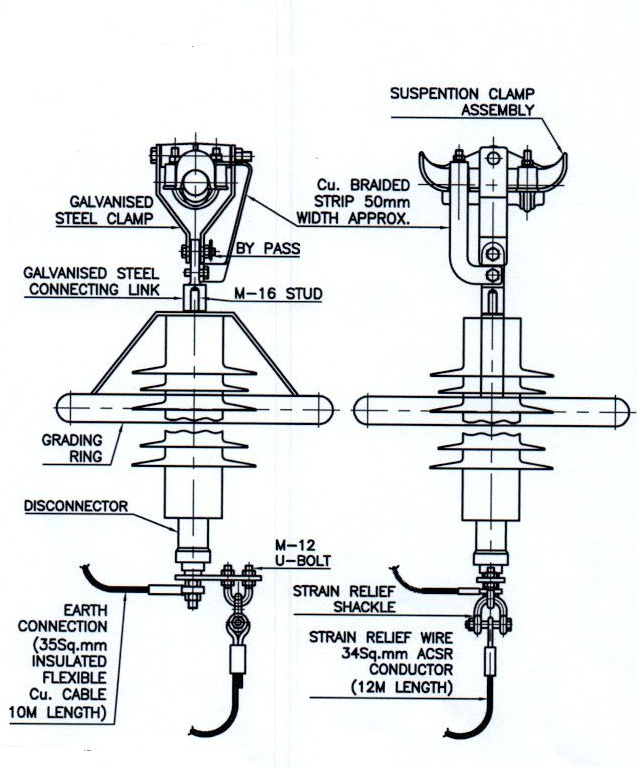

Components of TLSA. (NGLA_ Non gapped type surge arrestors) :-

The polymeric surge arrestor consist of a crimped cage, with stable ceramic doped Zinc Oxide oxide varistor blocks which are chemically bonded to a silicon rubber housing along the entire length of the core, The silicon insulation is made up of a non-halogenated silicon rubber with glass-fiber reinforced epoxy rods with end fittings and spacers made of Aluminum.TLSA are cage construction(open cage Construction ) is injection moulded covering all the internal parts including the end terminals in a single shot.

i )Suspension Pivot Clamp:

This is used to hang the surge arrester on transmission line. It takes the load of surge arrester, eliminates possibility of shifting of surge arrester on transmission line. Conductor fits between keeper and clamp.

ii)Copper braid/ Cable:

Copper braid is used for electrical continuity. It is connected between suspension clamp and arrester palm.

iii)Grading ring of arrester:

Metal part, usually circular in shape, mounted to modify electro-statically the voltage

distribution along the arrester, Used for equal voltage distribution along the TLA.

iv)Strain Relief arrangement: –

This arrangement helps to avoid mechanical stress on earth cable connected at base of disconnector due to swinging of NGLA. Essential for the longevity of the arrester to eliminate

v) Silicon Rubber Insulation housing :- Polymeric arrestor housing is used to provide Insulation for ZnO blocks as insulator housing /Jacket.

vi) MOV /ZnO :- The ZnO blocks are most important component of TLSA,Zinc oxide varistors . The active elements of Surge Arresters are known as Zinc Oxide Varistors, Non- linear Resistors , Voltage dependent resistors, varistors etc. A thicker varistor has higher threshold voltage and a device having a wider electrode area has a greater energy handling capability.

FRP rods around MO stack,Outer housing directly molded on to the MO stack ,Satisfactory mechanical strength ,Good short circuit performance.

vii)Grading Ring :- Used for equal voltage distribution along the TLA.

viii)Corona rings :- Corona Rings are used for reduction of the Corona Effect.

ix)Disconnector :- When an arrestor absorbs more energy than its ultimate capability ,the arrestor fails in a short circuit mode. The disconnector separates only in the event of an arrester from earth. Its explosive and important component of TLSA. The disconnector at the bottom most portion of the arrester is a very important functional agent. When the arrester fails, the same will become a dead short circuit to the earth which is not at all a desirable characteristic. Under such circumstances, the disconnector acts to isolate the arrestor from ground. With the ground lead, the connection to the earth is established. The length of this lead is also critical since the clearance with the other phases has to be validated. When NGLA fails, leakage current increases through surge arrester. this tends disconnector to operate and isolate NGLA from system thereby preventing perpetual fault on system and providing visual indication of failure.

x) Earth Connection:- Used to connect the arrestor to the ground.

xi) Leakage Current Monitor/Surge Monitor in series with TLSA showing the leakage current flowing in TLSA.

Maintenance and Testing of TLSA : –

Transmission line surge arresters have no maintainable components, maintenance activities are limited to inspection and regular health Monitoring & routine testing. TLSA to be monitored regularly .The rate of increase of leakage current leads to increase due to lightning & Switching surges and heat produced which lead to increase the leakage current and in ZnO element degradation takes place. The degradation of the factor is Lightning Impulse ,Entry of moisture, absorption of moisture in ZnO blocks,Enviornmental clearances, Increase of Zn0 blocks temp,Hot spot on top connector. The leakage current increases with respect to time.

During maintaince of TLA given below Health Monitoring Testing of TLA is to be carried out which is given below :

Insulation Resistance (IR) Test.

Thermo Vision Scanning

Leakage Current Monitoring.

Third Harmonic resistive current (THRC).

TLSA Failure Modes:-

The three main electrical failure modes of TLSA is Thermal runway,puncture and cracking .If the Temperature is increased ,impedance decreases and current increases .If the heat generated by the arrester current is greater than the heat dissipated by the arrestor housing ,the temperature of the arrestor will continue to increase. Thermal stability is one of the most important application criterion. When TLSA are exposed to energy beyond their capability the arresters. When line arrestors are exposed to energy beyond their capability the arrester will fail in a short circuit mode.

There are a number of mechanical and environmental stresses that may also lead to arrestor failure. Housing damage during transport or installation, or poor weather shed seal design,may allow moisture ingress and lead to flash over.Other failures include breaking of the disconnect assembly hardware and connection lead failure.

9.0 TLSA Experience in Indian grid :-Although the use of TLSA in Transmission Lines in world level was a very old concept but in Indian Grid it is accepted from 2019- 2020 and some of the manufacturers are manufacturing the TLSA.The have installed successfully Installed the TLSA up to 400kv voltage level ,TLSA minimized the Lightning related tripping’s in great extent.

CONCLUSION AND LESSONS LEARNT

The power system equipment can effectively be protected from the high magnitude overvoltage’s like lightning through the proper selection and installation of Transmission Line surge arresters as safety device and to maintain the reliability of the Transmission and distribution networks.The performance of transmission line mostly depends on the performance of the earthing. It is essential to reduce the tower footing resistance first to minimise the lightning related tripping if the tower footing resistance not reduce In lightning prone area so to minimise the tripping TLSA can be installed after proper power system studies. The installation of TLSA not 100 percent eliminate the lightening related tripping’s in lightning prone area having high ground flash density but it’s remedial measure to minimise the lightning related tripping in transmission lines.Lightning occurs when regions of excess positive and negative charge develop within the cloud. Typically, there is a large volume of positive charge in the upper regions of the cloud, a large negative charge in the bottom of cloud. The lightening is very mysterious & dynamic phenomenon we can minimize the lightning related tripping’s on large extent by installing the TLSA .

Author :- Er.Harshal Radheshyam Malewar .(Chartered Engg). B.E(Electrical ),MBA (Power Management ). 15 years of Experience in Transmission & Distribution sector.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.