Major regulations overhauled to face safety challenges

By EPR Magazine Editorial November 22, 2023 6:03 pm IST

By EPR Magazine Editorial November 22, 2023 6:03 pm IST

India has been facing an increasing demand for electricity while moving towards the vision of smart cities.

Electricity accidents are becoming increasingly prevalent nationwide, particularly in homes, industrial and commercial buildings, and hospitals. Most electrical accidents, such as “fire due to short-circuit,” are caused by ignorance and non-use of safety measures recommended by codes of practice, such as IS3043, IS732, and NEC.

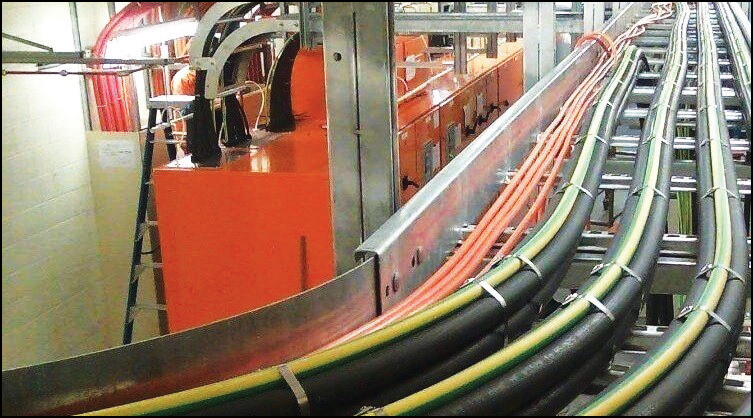

India has been facing an increasing demand for electricity while moving towards the vision of smart cities. But on the other side, the rate of electrical incidents is frequent, and the media viewed ‘short circuits’, as the main culprit of at least 65 percent of the total fire incidents. According to data from the National Crime Records Bureau (1), in 2015, about 2255 persons died due to fire caused by electrical short circuits. As per the data of the Indian Copper Association, 2016 witnessed 11444 electrical accidents involving 4799 deaths. The central electricity authority data attributes 40 percent of deaths at the workplace to electrical issues and 13 deaths on average per day by electrocution in India, which is the highest in the world. Electricity is recognised as a serious workplace hazard, exposing electric shock, thermal burns, fires, and explosions to human beings. Most of this is due to improper electrical installation and poor-quality products in India.

New Regulation and Standards

Regulations: The Central Electricity Authority (Measures relating to Safety and Electric Supply) regulations are the mandatory requirement to be followed in every electrical installation. The erstwhile 2010 regulations were replaced by a new regulation in June 2023. It is to be noted that the new regulation has a variety of changes compared to the old ones. Fault loop impedance is introduced as a new component as a mandatory safety testing after installation to determine the effectiveness of the automatic disconnection during fault conditions. Earth resistance has been removed from the standard for low-voltage installations. This is a major change as the earthing system followed till now is the TT system, which mandates the use of 30 mA RCD at the origin of the installation. Hence, supply cannot be used in most installations due to nuisance tripping, and only the TN-S system becomes usable in India. Since the earth electrode resistance test is removed, the significance of earth pits is reduced.

Standards: The National Electrical Code of India (NEC 2023) was released this year. This code is also made mandatory by the CEA regulation. The National Electrical Code of India explains the importance of class 2 copper wire, TN-S system and Equipotential Bonding. This will lead to a low fault loop impedance in a typical installation. The lower the impedance, the more the current will be passing through the circuit, leading to faster disconnection of overcurrent protective devices.

In India, predominantly Class 5 copper wire is used in fixed wiring. Class 5 copper wire will have more resistivity than Class 2 and is widely used because of its cheap cost. In a TN-S system, the earth fault current travels back to the source via a metallic conductor called a P.E conductor or protective earth conductor. The previously used TT system enables the fault current to travel back to the source via earth (soil through earth electrodes), but this creates a large impedance in the loop, and the current will not be enough to trip the protective devices. Due to this, the TN-S system is made mandatory.In large residential, commercial, and industrial buildings, PME earthing is also recommended in NEC 2023. The PME system has additional fault return paths as well as low touch voltages, making the premise more safe. Equipotential Bonding is also an important measure for shock protection in residential and commercial premises. All exposed and extraneous conductive parts of an installation (e.g. metal pipes, metal rebars, etc.) are bonded to a Main Earth Terminal or MET. This ensures that there is no potential difference between two simultaneously accessible metal parts in case of fault, which means it will be equipotential. This ensures no shock during fault conditions.

Conclusion

Due to the publication of these Codes, Standards and Regulations, the electrical installations will drastically change in a few years. The accidents due to electricity will be reduced. These measures are being taught and spoken in the electrical population through the courses and awareness classes taken by the Bureau of Indian Standards and the National Federation of Engineers for Electrical Safety (NFE).

Authored by– Nandu Gopan- Member of the Bureau of Indian Standard (BIS) in ETD 20 (Electrical Installation Sectional Committee)

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.