Durability of anti-reflective coatings of solar glass

By EPR Magazine Editorial February 2, 2024 3:36 pm IST

By EPR Magazine Editorial February 2, 2024 3:36 pm IST

Rayzon Solar, a prominent solar panel manufacturing company, has recently conducted a comprehensive assessment to evaluate the durability of its anti-reflective coatings. The results of this study showcase the company’s commitment to ensuring long-lasting and efficient solar panel performance. These findings reinforce Rayzon Solar’s position as an industry leader dedicated to advancing the sustainability and reliability of solar energy solutions.

1. Introduction

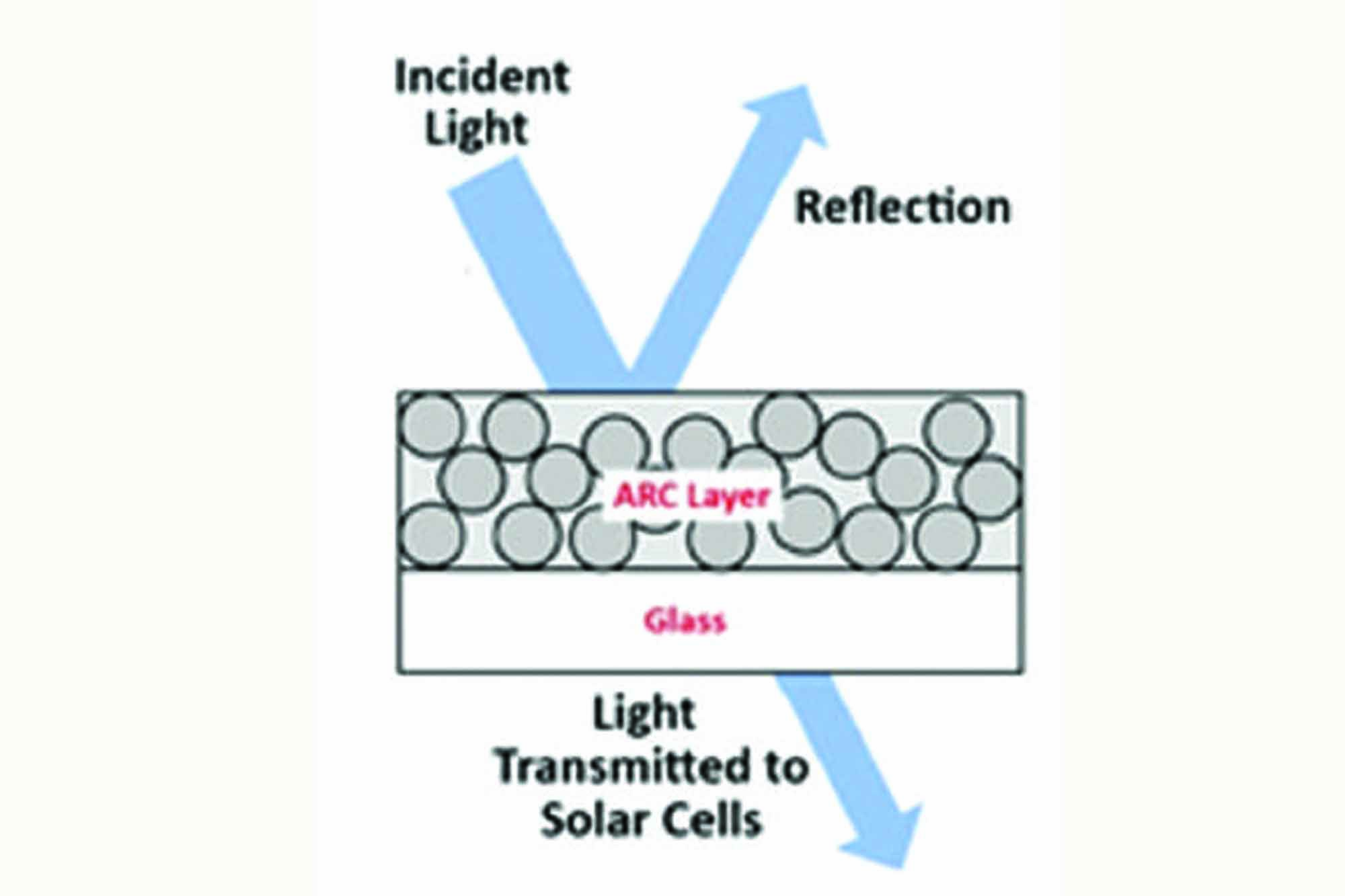

Rayzon Solar employs advanced technologies to enhance the efficiency of solar panels. Anti-reflective coatings (ARCs) are applied to the glass surface of solar panels to reduce reflection losses and increase power generation. The effectiveness of these coatings is determined by the refractive index (RI), ideally falling within the range of 1.23 – 1.27. Rayzon Solar utilises cost-effective nano-porous silica-based coatings filled with air to achieve optimal transmittance, boosting glass efficiency by up to 2 percent.

2. Durability of the Coating

The SiO2 based ARC coating on the solar glass is only around 100 nm thick (which is 1/500 times the thickness of human hair) and can get damaged if not carefully maintained. The various factors that can cause degradation of the ARC coating are discussed below.

a) Abrasion during module cleaning:

The porous ARC coating is susceptible to abrasion damage from module cleaning if a hard brush is used. The thinning of the ARC coating layer due to abrasion will lead to a change in the reflectance pattern (minima shifting to shorter wavelengths). Also, the reflectance increases as the coating is removed from the glass surface. So, such abrasion can also lead to discolouration of the ARC coating.

b) Water stagnation on glass:

The pores in silica-based ARC coatings tend to readily adsorb water from the atmosphere (more so if water is allowed to stand on the glass) and also react with the organic compounds or carbonates dissolved in water. Such contamination may increase the effective refractive index of the coating leading to reduced anti-reflection effect (higher reflection of light). This may also lead to the rainbow-type discolouration observed at the bottom of the solar panels (where water usually stagnates in panels installed at low tilt angles). The adsorbed water can be removed from the ARC coating at high temperatures in the range of 55 – 135 °C [1]. So, the discolouration may disappear in the summer season when the module temperature exceeds 55 °C for long periods.

c) Reaction with organic materials:

Some ARC coatings show temporary stains upon field exposure in residential and heavy pollen areas (depending on the porosity and the size of the pores in the ARC coating). The trapping/reaction of the organic materials (like plant seeds or pollens) in the ARC coating pores leads to small silvery or brown spots, which disappear within 1-2 months of exposure to sunshine [3]. The loss in power generation is marginal (<1%) due to such discolouration, as the affected area is very small compared to the module area.

3. Preventive MeasuresThe life of the Silica based ARC coating (usually 5 – 7 years) can be maximised if proper measures are adopted to prevent its untimely degradation, as discussed below.

a) Use water drainage clips:

Water should not be allowed to collect on top of the solar panels for a long duration. For modules with a high tilt angle (greater than 20°), the water will naturally drain from the solar panels. For modules installed at lower tilt angles, water will not completely drain out and can stagnate at the bottom edge of the solar panels which can then lead to discoloration of ARC coating. To avoid such discolouration due to stagnating water, it is recommended to use water drainage clips as shown in the figure below.

b) Use a soft brush or squeegee for cleaning panels

Brush with soft bristles or Squeegee (having rubber blades) is recommended for cleaning the solar panels.

c) Use only fresh water for module cleaning

Use fresh water with a Total Hardness of <75 mg/litre for cleaning the modules to minimise the reaction of ARC coating with the dissolved carbonates.

4. Conclusion

Rayzon Solar emphasises the crucial role of ARC coatings in enhancing power generation from solar panels. The thin nature of the coating requires careful handling. Recommendations include avoiding water stagnation, using soft cleaning tools, and employing fresh water for cleaning. The durability of Rayzon Solar’s ARC coating ultimately lies in the hands of end-users, and their active involvement can significantly contribute to its longevity.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.