Why smart grid is the future of power sector

By EPR Magazine Editorial April 3, 2017 2:21 am

By EPR Magazine Editorial April 3, 2017 2:21 am

Analysis on how smart technologies — and the practices they enable — can impact the operation and overall health of the grid.

The electrical grid is evolving. The traditional grid was pretty simple. It was unidirectional, with centralised power being generated mostly through conventional sources such as hydro and thermal, and then transmitted to load centres and consumers. With global stress on reducing the carbon footprint while targeting the respective country’s growth levels, the power generation is getting distributed with increased penetration of renewable energy. Thus, the evolving grid has new complexities, with bi-directional power flow, which by nature of harnessing renewable sources will be intermittent and unpredictable. Consumption trends are also changing with the new demands of industry, smart cities and urbanisation.

In today’s parlance the automation solutions implemented across the power system network is known as “Smart Grid”. In this context, a smart grid can be understood as an evolved grid system that manages electricity demand in a sustainable, reliable and economic manner. It is built on advanced infrastructure and tuned to facilitate the integration of all involved in the entire power ecosystem – from generation to distribution and consumption. Smart grid technology is not a single technology, rather a collection of existing and emerging technologies working together. A smart grid is a combination of intelligent devices in the field like the transformers, circuit breakers etc. with sensors and powerful control systems with the convergence of OT (Operation Technology) and IT (Information Technology) for centralised monitoring and control. When properly implemented, these technologies will increase efficiency in production, transport and consumption, improve reliability and economic operation, integrate renewable power into the grid, and increase economic efficiency through electricity markets and consumer participation.

There are different aspects that a Smart Grid is expected to improve in the power system operations, like

Optimise asset utilisation and operating efficiency.

Some examples of how smart technologies—and the practices they enable—can impact the operation and overall health of the grid include the following:

Microgrids

As the percentage or penetration of renewables increase in a power system, it becomes imperative to have grid level power balancing using energy storage systems. Microgrids are expected to form an inherent component in the grid system with localised generation and storage as close to the load centers as possible. They can be differentiated from major powergrids in the sense that they are usually integrated at the distribution system of the power system, limited to integration at low or medium voltage levels of the grid. They are limited in geographical reach unlike power grids, and they lack bulk power transmission capabilities. Microgrids are thus more localised where the generation and consumption happens within a small area.

One may visualise Microgrid as a part of a power system with generation, having a mix of renewable and conventional, with storage elements for grid stabilisation added (if a high penetration of renewable has to be achieved within the Microgrid so formed) enabling independent operation to be achieved with or without provision to be connected to a grid.

Demand Response is a program to control and change the end customer energy consumption pattern depending on the factors like time of use price, peak shave-off incentives. Peak shave-off is reducing the consumption to reduce and bring down the peak levels, so that the electrical network can deliver without any disturbances arising due to overloads.

As peak shave off is more important from the utilities perspective to maintain the operating conditions of the grid, incentive payments are normally included to encourage end customers to volunteer and subscribe to the program. The time-of-use consumption will trigger self-interest in the end customer to use the appliances based on the tariffs fixed at different time of the day. DR opens up a disciplined usage of energy by intentionally altering the time of usage of home appliances. Demand Response is a voluntary program where the end customer “participates” in helping the utilities to manage the energy distribution.

The implementations of Advanced Metering Infrastructure (AMI), which enables bi-directional communication between the utility system and the consumer devices/appliances and Microgrids systems are widely viewed as enabling technologies for demand response that will permit greater and more effective use of demand response strategies.

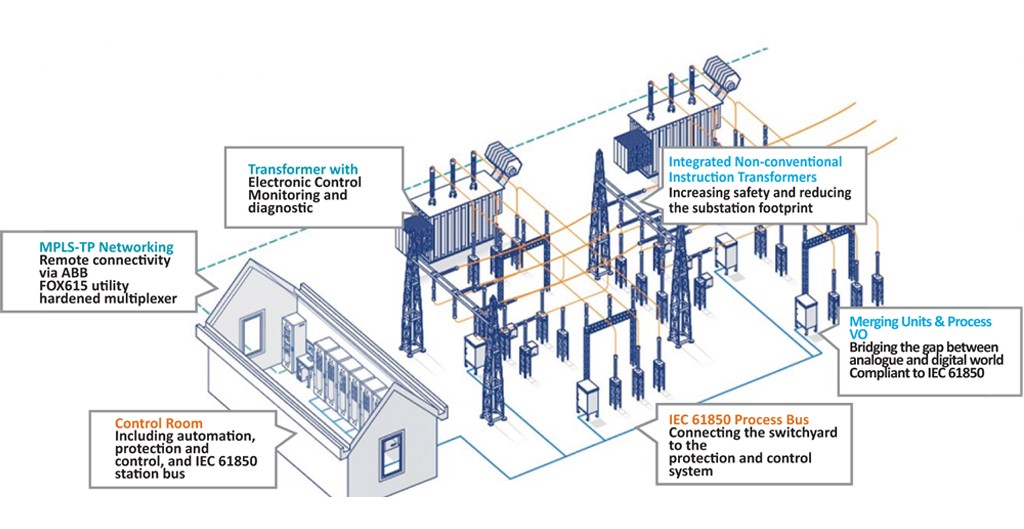

Digital Substations

Digital Substation is a significant breakthrough innovation in substation technology. It is based on the seamless integration of state-of-the-art IEC 61850 based control and protection IEDs with all relevant primary components and sensors of a modern substation. The primary components include extra-high and medium-voltage switchgear, as well as substation transformers.

Digital Substations remove the last electrical connection between the high voltage equipment and the protection and control panels, creating a safer work environment, whilst reducing the costs for building, land, engineering, commissioning, operation and maintenance of the system. As a key component towards smarter grids, where utilities continue to integrate increasing amounts of intermittent renewable energy sources, Digital Substation is a core enabler to increase safety, productivity and reliability for grid operators and to reduce the overall substation cost. It’s a key enabler for the electric power utilities to increase productivity, reduce footprint, increase functionality, improve the reliability of assets and, crucially, improve safety for service personnel. Digital Substations exploit the benefits of digital protection, control and communication technologies, mirroring the trend towards digitalisation seen in many other industries.

The defining feature of a Digital Substation is the implementation of a process bus. The IEC 61850 process bus enables the substitution of point-to-point copper connections between IEDs, other devices (e.g. instruments transformers, gas monitoring, etc.) and switchgear by means of a safe, standardised optical communication bus. The process bus enables real-time measurement signals and status information to be broadcasted throughout a substation without complex wiring schemes.

The key Digital Substations technologies include:

High Voltage Primary Equipment: Primary High Voltage switchgear in Air Insulated Technology (AIS), Gas Insulated (GIS) or Hybrid Technology (PASS) non-conventional instrument transformers enable smaller substation foot print and easier engineering. Alternatively, existing CTs & VTs can be connected to Stand Alone Merging Units, which connect the analogue measurement signals to the process bus.

Protection, Supervision and Control: The substation automation, protection and control system solutions ensure reliable power transmission and distribution. To ensure interoperable and future-proof solutions, the substation automation, protection and control system has to be designed to implement the core values of the IEC 61850 standard.

Medium Voltage Switchgear: Air and gas insulated switchgear solutions for primary and secondary distribution that suits various applications like railway power supply and wind farm integration.

Communication Networks: The Communication Network inside the substation and from the substation to remote network control centers. These solutions fulfil the highest demands with respect to safety, reliability, and real time response.

The equipment level implementation of a Digital Substation can be extended to further enhance the operational and maintenance efficiencies with the applications for monitoring, diagnostics and asset management.

Authored by

Vijayan SR, Asst VP, Technology Manager, Smart Grids and Cyber Security, Power Grids Division, ABB India Limited

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.