How does a digital-platform framework help you achieve your objectives?

By EPR Magazine Editorial February 10, 2023 3:21 pm IST

By EPR Magazine Editorial February 10, 2023 3:21 pm IST

Industry 4.0 introduced the concept of automating industrial workflows to reduce errors, increase shop-floor safety, and increase productivity. The concept behind automating these workflows rests on developing a framework of digital industrial solutions with the ability to drive interconnectivity, capture data, and analyse the captured data to empower automated systems with machine vision or machine learning capabilities. Integrating the use of a digital platform provides the enabling environment that digital technologies require for delivering the benefits of Industry 4.0.

What are digital-platform frameworks?

The traditional concept of digital platforms refers to the interfaces such as Facebook, Twitter, and Instagram that dominate the social media space. However, in the industrial sector, digital platforms refer to service-oriented platforms that support communication, data collection, and analysis within a facility. These digital platforms become the framework for managing an industrial enterprise’s IT and interrelated OT infrastructure.

Digital platforms leverage a centralised computing resource framework—the cloud or on-premises infrastructure—to host applications and app development tools. These applications and tools, such as APIs or machine-learning apps, can be industry-specific or generic for all industries. For example, using a digital platform built to support manufacturing digitalisation gives manufacturers the tools to develop very technical apps from scratch that wouldn’t be found in the average Play Store or iTunes Store.

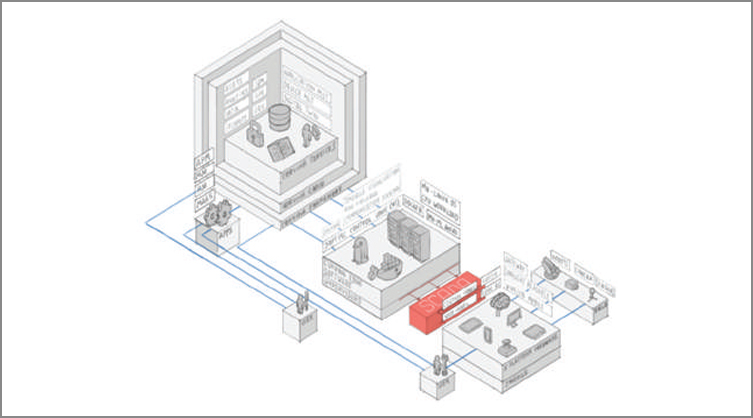

Focusing on the manufacturing industry, the image below highlights the industry-specific nature of a digital-platform framework that supports industrial use cases.

The framework provides extensive support for the edge, near-edge, smart, and automated systems deployed on the shop floor. The framework showcases the storage and computing assets needed to power a digital platform, the data-producing devices, and the apps for collecting and analysing captured data. The insight and data captured within the framework are accessed using the web and mobile apps, as can be seen in Figure 1. The capabilities of the average digital platform can be categorised as offering the following:

Leveraging digital platforms to implement Industry 4.0

With approximately 81 percent of manufacturing enterprises adopting increasingly advanced digital transformation solutions, providing answers to the question “Why go the digital route?” is no longer valid. Today, everyone understands the productivity and operational benefits that come with embracing digital transformation. A digital-platform framework integrates all digitalisation tools into a single virtual environment. Thus, a manufacturer gets a singular environment for managing every digital and physical asset deployed on the shop floor from a single platform.

Validation and testing: reducing failure rates when implementing new technologies or strategies on the shop floor is important to reducing implementation costs. A centralised digital platform provides the tools for assessing the effects of implementations using VR headsets or analytics software to analyse related data sets.

Build or buy digital industrial solutions: digital-platform frameworks

Manufacturers interested in adopting digital platforms to ease manufacturing operations have two choices before them: build their platform from scratch or buy into an existing platform. Making the right decision involves understanding some important factors. These considerations include:

Security: Many manufacturing enterprises choose to build their platforms with security challenges as the deciding factor. 75 percent of enterprises name cloud security as their biggest challenge with purchasing digital solutions, and these concerns are legitimate. Although building your platform provides a measure of the security factor. these platforms must be properly configured because poor configuration accounts for 68 percent of successful data breaches. The negative effects of misconfiguration once again raise the question of how competent the in-house personnel are at building and managing a digital platform.

The decision to buy or build rests on the shoulders of C-level executives, who must consider their industrial enterprise’s key competencies before deciding. The cost and technical requirements for building digital platforms make purchasing a more attractive option for small and medium-sized businesses. However, large businesses that choose to build generally partner with reputable industrial solutions providers to meet their building requirements.

For more details, please visit: www.exorint.com/en/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.