Discovering origins of electrical fires and electrocutions

By EPR Magazine Editorial June 19, 2024 11:31 am IST

By EPR Magazine Editorial June 19, 2024 11:31 am IST

Analyse the causes of electrocution and fire hazards in various settings, highlighting the high reliance on electrical power supply in modern society.

Abstract: Nowadays, modern society is highly dependent on electrical power supply. To live & make our life comfortable, we use number of appliances/gadgets at our residence/office. Every day we get up with the news of electrocution or electrical fires in residential or commercial buildings or public location or distribution transformer or substation. This forces us to ponder over the reasons/ causes of such accidents which lead to loss of lives as well as assets/properties. This paper provides root cause analysis of different causes of electrocution or fire hazards for all locations.

Fig. 1 ELECTROCUTION AND ELECTRICAL FIRE ACCIDENTS

Nowadays, modern society is highly dependent on electrical power supply. To live & make our life comfortable, we use number of appliances/gadgets at our residence/office.

Electrocution, Electrical fire and Lightning kill 15,000 a year. Also 75000 (approx.) suffer because of these deaths, there is loss of property and assets, dreams of many people associated with deceased shatter.

Around 1 lakh people died due to electrocution in the last decade, as per NCRB data (please refer table 1).

NCRB DATA OF DEATHS DUE TO LIGHTNING ELECTROCUTION AND SC FIRE 2020-222

The news of electric shock or electric fire killing people gives pain and forces everyone to find the solution but in a day or two we again forget and wait for another accident to happen. (Refer figure 1)

There are too many tales that different parts of the country have to tell each day without fail (many cases are even not reported or recorded).

Keeping the figure for the injured aside, the numbers for the electrocution deaths in the country tell a story of their own. According to the National Crime Records Bureau, around one lakh people lost their lives because of electrocution in the last decade alone. The annual average of fatalities rose to 12,500 per year or 30 fatalities every day.

Calling the 30 electrocution deaths per day in India “accidents” is something which is not justified as it tends to insulate all stake holder from accountabilities.

MAIN CAUSES OF ELECTROCUTION & ELECTRICAL FIRE HAZARD

Electrocution & Electrical Fires in Electrical Installation may be broadly caused by

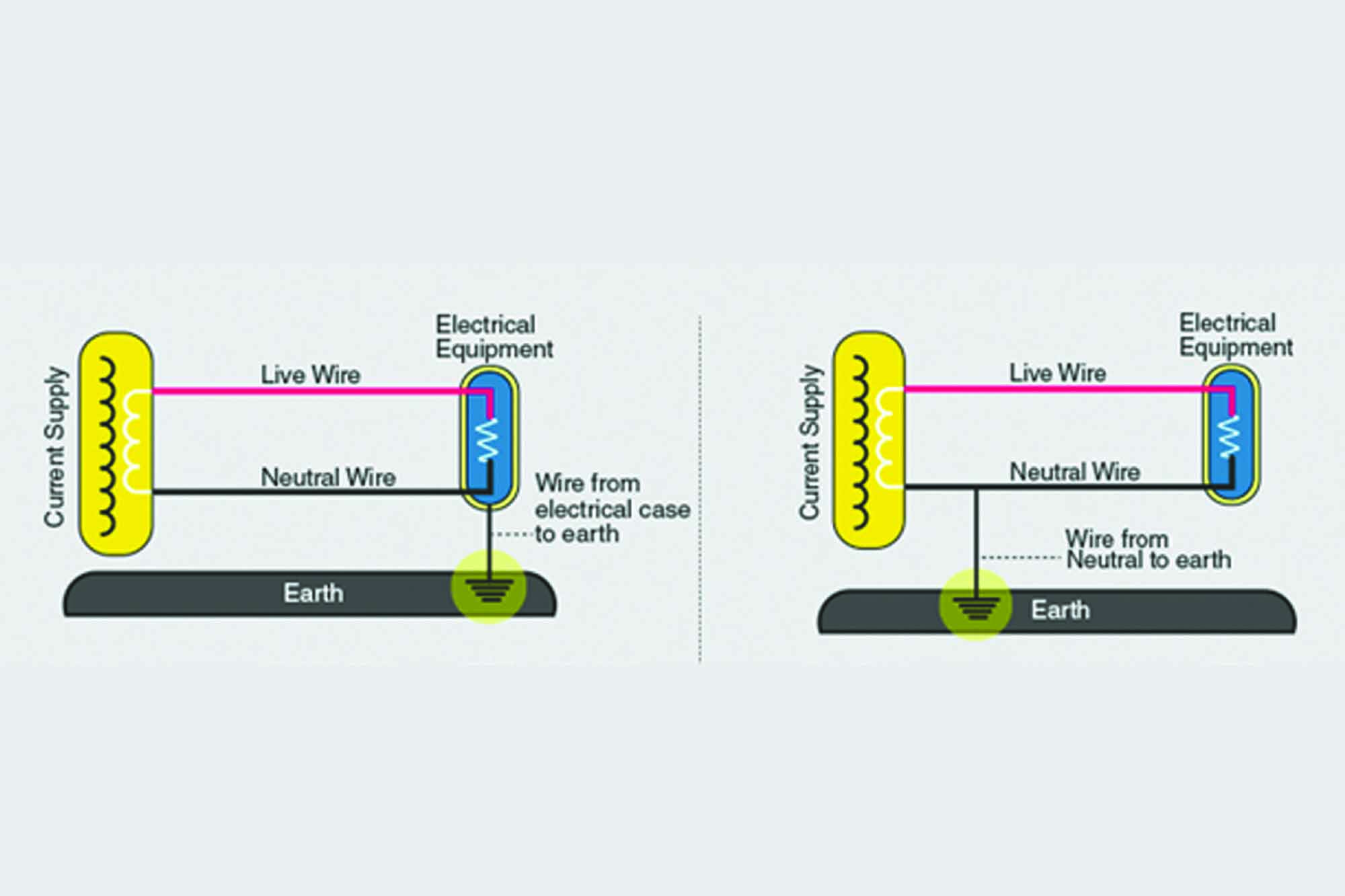

ROLE OF ADEQUATE EARTHING/GROUNDING

Grounding/ Earthing means making a connection to the general mass of earth. The use of grounding is so widespread in an electric system that at practically every point in the system, from the generators to the consumers’ equipment, earth connections are made.

There are two types grounding (Refer figure 2):

Fig.2 EQUIPMENT AND NEUTRAL EARTHING

The objectives of General Grounding system include:

UNEARTH SYSTEM AND SHOCK HAZARD

The main objective of grounding electrical systems is to provide a suitably low resistance path for the discharge of fault current which ultimately provides safety to working personnel and costly installed equipment by providing sufficient current to safety devices.

2.2 BASIC OF SHORT CIRCUIT IN THE ELECTRICAL SYSTEM

Electrical fires very often take place in residential sector. This is because most of the people do not account for the rating of the appliances while placing or connecting them. Being an individual, most of us are not aware about the parameters we need to consider while purchasing the product. The only thing that people look for is the cost effectiveness which in turn leads to extreme situation resulting in electrical fires. Major reason for electrical fire in LV system is Short Circuiting i.e. flowing of current through unintended path.

A short circuit is an abnormal connection between two nodes of an electric circuit intended to be at different voltages. This results in an electric current limited only by the equivalent resistance of the rest of the network which can cause circuit damage, overheating, fire or explosion (please refer figure 4).

This high current generates high heat and presence of fuel or any other flammable materials may result in the fire hazard as governed by fire triangle in figure 5.

Fig.5 FIRE TRIANGLE

Short circuit happens mainly due to degradation of insulation. As the wire gets old, the insulation gets degraded, due to which there is a chance of short circuiting (figure 6) & this may lead to fire.

MAIN CAUSES OF ELECTROCUTION AND ELECTRICAL FIRE – DIFFERENT LOCATIONS

Electrocution and fire hazards pose significant risks to individuals and properties in various settings, including homes, commercial buildings, public places, public processions and substations. These hazards can result in devastating consequences, including loss of life, injuries, and extensive property damage. Understanding the causes behind these incidents is crucial for implementing preventive measures and ensuring safety in these environments. In this section, we will explore the primary causes of electrocution and fire in each of these settings.

Electricity is not something to play around with – neglect and carelessness lead to both electrocution and fire at our homes. Homes are where individuals spend a significant portion of their time, making them susceptible to electrical hazards if proper precautions are not taken. Commercial buildings house various electrical systems to support operations, making them susceptible to electrical hazards if not adequately maintained. Several factors contribute to the risk of electrocution and fire in residential as well as commercial places).

Public places, such as schools, hospitals, shopping malls, and recreational facilities, accommodate large numbers of people, making electrical safety paramount (refer figure 7). Electrocution in public places is also evidence of power companies and governments cutting corners. Safety requires discoms to take all high-tension cables underground. But power companies resist this for the costs entailed and direct impact on electricity tariff.

Fig.7 FIRE IN HIGH RISE COMMERCIAL BUILDING

Causes of electrocution and fire in public places include (apart from above causes in table 2) are discussed below:

a. Aging Infrastructure: Older public buildings may have outdated electrical systems that are more prone to faults and failures, increasing the risk of electrical incidents.

b. Lack of Maintenance: Inadequate maintenance of electrical systems and equipment in public facilities can lead to deteriorating conditions and potential hazards.

c. Overcrowding: Events or facilities that experience overcrowding may put strain on electrical systems, increasing the likelihood of overloads and electrical fires.

d. Improper Installation: Faulty installation of electrical systems or equipment in public places can create hazardous conditions that endanger occupants and visitors.

e. Vandalism or Sabotage: Deliberate acts of vandalism or sabotage targeting electrical infrastructure in public places can result in electrocution hazards and fires. (Refer figure 8)

ELECTROCUTION HAZARD DUE TO POOR UPKEEPING / THEFT

Public processions and gatherings hold significant cultural, religious, and social importance in India, often involving large crowds congregating on streets. However, amidst the fervor and celebration, safety concerns often take a backseat, leading to tragic incidents like electrocution & fire.

Causes of Electrocution

1. Improper Wiring: Inadequate or faulty wiring setups are common during public events due to hasty installations or lack of expertise. These setups may include temporary electrical connections that are not insulated properly, increasing the likelihood of electrocution if they come into contact with water or damp surfaces.

2. Overloaded Circuits: The demand for electricity surges during festivals and processions due to extensive lighting arrangements, sound systems, and other electrical paraphernalia. Overloading circuits beyond their capacity raises the risk of short circuits and subsequent electrocution hazards.3. Poor Maintenance: Existing electrical infrastructure often receives minimal maintenance, exacerbating risks during public gatherings. Aging cables, corroded connections, and neglected equipment pose significant threats when subjected to the additional strain of large-scale events.

4. Unauthorised Installations: In the rush to set up for festivities, unauthorised installations by unqualified personnel are common. These makeshift arrangements bypass safety protocols, heightening the probability of accidents such as electrocution.

5. High-Tension Wires : High-tension wires, also known as high-voltage power lines, carry electricity over long distances at high voltages. These wires are typically installed on tall transmission towers or poles to ensure clearance from the ground and surrounding structures. However, during public processions, temporary structures such as stages, pandals (decorative tents), or banners may inadvertently come into contact with these wires, leading to catastrophic consequences. (Refer figure 9)

ELECTROCUTION & FIRE DUE TO PUBLIC PROCESSION

Causes of Electrocution Due to High-Tension Wires

1. Inadequate Clearance: Temporary structures erected for public processions often lack proper planning and supervision, resulting in insufficient clearance between the structures and overhead high-tension wires. Failure to maintain adequate distance increases the risk of accidental contact, especially when structures sway due to wind or crowd movement.

2. Ignorance and Negligence: Organisers and participants may lack awareness about the dangers posed by high-tension wires or fail to recognise the potential hazards associated with erecting structures near them. Ignorance coupled with negligence in adhering to safety guidelines exacerbates the risk of electrocution incidents.

3. Lack of Coordination: Coordination between event organisers, local authorities, and power distribution companies is often inadequate, leading to haphazard planning and implementation of safety measures. Failure to coordinate activities such as route planning, structure placement, and crowd management increases the likelihood of accidents involving high-tension wires.

4. Encroachment and Unauthorised Construction: Encroachment on public spaces and unauthorised construction near high-tension wire corridors is a common phenomenon in many Indian cities and towns. Informal settlements, temporary shelters, and makeshift structures often encroach upon the safety buffer zones around high-tension wires, heightening the risk of electrocution during public processions.

Electrocution due to contact with high-tension wires during public processions represents a preventable tragedy that underscores the need for concerted action and collective responsibility. By raising awareness, enforcing regulations, conducting pre-event inspections, integrating safety into structural planning, and enhancing emergency response preparedness, India can mitigate the risks associated with high-tension wires and ensure the safety and well-being of its citizens during festive celebrations. Only through proactive measures and collaborative efforts can help in getting rid of danger of electrocution from India’s public gatherings, allowing communities to celebrate their cultural heritage in safety and solidarity.

3.4. ELECTRICAL SAFETY AT INDUSTRIAL LOCATION, GENERATING STATION & SUBSTATIONS

Industries, generating station and substations are critical components of electrical networks, but they also pose significant risks if safety measures are not strictly enforced (Refer figure 10). Causes of electrocution and fire in substations include:

a. High Voltage Exposure: Industries & substations contain high-voltage equipment that poses a severe risk of electrocution to untrained personnel or trespassers who come into contact with live components.

b. Equipment Failure: Malfunctions or breakdowns of transformers, circuit breakers, and other substation equipment can result in electrical arcs, sparks, and fires.

c. Lack of Proper Enclosure: Unprotected or poorly enclosed panels or substations may expose electrical components to environmental factors such as moisture, debris, and wildlife, increasing the risk of failures and fires.

d. Inadequate Security Measures: Substations that lack sufficient security measures are vulnerable to unauthorised access, which can lead to tampering, theft, or vandalism that compromises safety.

e. Insufficient Training: Workers at factories or substations must receive comprehensive training on electrical safety protocols and emergency procedures to mitigate risks effectively.

Fig.10 FIRE IN GENERATING STATION AND EHV SUBSTATION

Seven Golden Rules to Ensure Safety for Industrial locations and Substation or Generating Station are given below in the table 3.

TABLE 3 SEVEN GOLDEN RULES TO ENSURE SAFETY FOR INDUSTRIAL LOCATION, GEN STATION & SUBSTATION

| Sr. No. | Descriptions |

| 1 | Evaluate the work to be performed. Do an on-site risk assessment or hazard analysis. |

| 2 | Ensure that you clearly identify the work location and equipment where the maintenance work is to be carried out. |

| 3 | Always apply permit to work and discuss the work to be carried out in detail with team who is going to perform the work. |

| 4 | Always disconnect electrical sources and secure against reconnection in any condition. |

| 5 | Verify the absence of operating voltages. Test before touching/ starting any activity |

| 6 | Ensure to carry out Earthing of the part where the work is to be carried out by team. |

| 7 | Protect adjacent live parts and take special precautions when working close to the bare conductors. |

3.5 ELECTROCUTION AND FIRE HAZARDS DUE TO CONTACT WITH OVERHEAD POWER LINES OR SNAPPING & FAILURE OF DT

India’s rapid urbanisation and industrialisation have led to an exponential increase in demand for electricity. As a result, the country has witnessed a significant expansion in its power network infrastructure, including overhead power lines and distribution transformers. However, this growth comes with inherent risks, particularly concerning electrocution and fire hazards due to the snapping of overhead power lines and malfunctioning distribution transformers.

The snapping of overhead power lines or accidental contact with HT conductor (bare) poses a grave risk of electrocution to individuals in close proximity. The high voltage carried by these lines can instantly incapacitate or fatally injure anyone who comes into contact with them. This danger is exacerbated in densely populated areas, where overhead power lines often crisscross residential neighbor hoods, posing a constant threat to unsuspecting residents, especially children and pedestrians. (Refer figure 11)

Fig.11 ELECTOCUTION DUE TO LADDER IN CONTACT WITH HT WIRE

Furthermore, inadequate maintenance and aging infrastructure increase the likelihood of power line failures. Corrosion, wear and tear, and environmental factors such as storms and strong winds can weaken the structural integrity of power lines, making them susceptible to snapping. In rural areas, where electricity infrastructure may be less robust, the risk of electrocution due to snapped power lines is particularly pronounced, as prompt intervention and repair may be delayed.

Distribution transformers play a crucial role in supplying electricity to homes, businesses, and communities across India. However, these transformers are not immune to faults and malfunctions, which can lead to catastrophic fires. One common cause of transformer fires is overloading, wherein the transformer becomes overwhelmed by excessive demand, causing its components to overheat and ignite flammable materials nearby.

Fig.12 FIRE DUE TO DISTRIBUTION TRANSFOR FAILURE

Inadequate cooling systems, poor maintenance, and substandard materials further exacerbate the risk of transformer fires. Over time, the insulation materials within the transformer degrade, increasing the likelihood of internal arcing – a phenomenon where electrical discharge occurs within the transformer, generating intense heat and sparks. If left unchecked, these sparks can ignite the transformer’s oil coolant, triggering a rapidly spreading fire. (Refer figure 12)

Electrocution and fire incidents involving overhead power lines and distribution transformers have far-reaching consequences for public safety and infrastructure integrity. Beyond the immediate loss of life and property damage, such incidents can disrupt electricity supply to entire communities, leading to widespread blackouts and economic losses. Moreover, the collateral damage caused by fires – including damage to nearby buildings, vegetation, and infrastructure – further compounds the impact on affected areas.

In urban settings, where population density is high and buildings are closely clustered, transformer fires pose a significant threat to public safety. The rapid spread of fire can overwhelm fire fighting efforts, putting residents and emergency responders at risk. Additionally, power outages resulting from transformer failures can disrupt essential services such as hospitals, communication networks, and water supply systems, exacerbating the crisis

3.6 ELECTROCUTION AND FIRE HAZARDS DURING RAINY SEASON

India, a country characterised by diverse cultures, traditions, and climatic conditions, faces numerous challenges related to safety during the rainy season and public processions. Among these challenges are the risks of electrocution and fire accidents, which become more pronounced during these periods.

Fig.13 ELECTROCUTION DURING RAINY SEASON

The rainy season in India, typically spanning from June to September, brings relief from scorching heat but also poses threats, especially concerning electrical safety. The combination of heavy rainfall and inadequate infrastructure often leads to electrocution incidents. Poorly insulated wires, malfunctioning electrical appliances, and flooded areas create a lethal environment where even a slight negligence can result in fatal accidents. Moreover, the lack of awareness among the populace exacerbates the risks, as many people are unaware of basic safety measures during monsoons.

One of the primary causes of electrocution during the rainy season is the waterlogging of streets and residential areas. Puddles of water become conductors of electricity, turning seemingly harmless locations into potential death traps. Additionally, damaged power lines dangling precariously or submerged in water pose imminent dangers to unsuspecting individuals. Moreover, the practice of illegal tapping of electricity, rampant in many parts of the country, further heightens the risk of electrocution, as makeshift connections are often poorly insulated and vulnerable to water ingress. (Refer figure 13)

The consequences of electrocution accidents during the rainy season are often catastrophic. Loss of life, injuries, and property damage are common outcomes of such incidents. Families are torn apart, livelihoods disrupted, and communities traumatised by the sudden and preventable loss of loved ones. Furthermore, the economic burden resulting from medical expenses, legal proceedings, and compensation claims adds to the already dire situation. Moreover, electrocution accidents can also lead to power outages, disrupting essential services and causing inconvenience to the public.

CONCLUSION (RECOMMENDATIONS & SAFETY TIPS)

1. Regular Maintenance & Condition Monitoring testing of all the equipment in the system must be done periodically to avoid any hazards. The list of test to be conducted are summarised in the table 4 below.

TABLE 4 TEST TO BE CONDUCTED AS PER IS 732

By implementing these recommendations, individuals and organizations can significantly reduce the risk of electrocution and fire hazards in various locations.

REFERENCES

| [1] | Manual on,” Grounding of A C Power Systems,” Publication No 339, C.B.I.P. New Delhi. |

| [2] | IS 3043-2018,Indian Standard Code of Practice for Grounding. |

| [3] | CEA ‘Measures relating to Safety and Electric Supply’ and ‘Technical Standards for Construction of Electrical Plants and Electrical Lines and Connection to Grid under Regulations 2010. |

| [4] | IS 732: Code of Practice for Electrical Wiring Installations |

[5] | IS/IEC 62305 – Protection Against Lightning |

[6] | National Building Code 2016 |

[7] | National Electrical Code (NEC) 2023 |

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.