Intelligent transformer monitoring system for grid with cost reduction & extended service life

By EPR Magazine Editorial July 31, 2023 3:21 pm IST

By EPR Magazine Editorial July 31, 2023 3:21 pm IST

Gujarat Power Research and Development (GPRD) sought a comprehensive real time monitoring system for transformers. System Level Solutions (SLS) developed an Intelligent Transformer Monitoring System with IoT technology, providing real-time data for predictive and preventive maintenance.

Challenge: The unavailability of a real-time transformer monitoring system leads to high downtime and increases the risk of transformer burning.

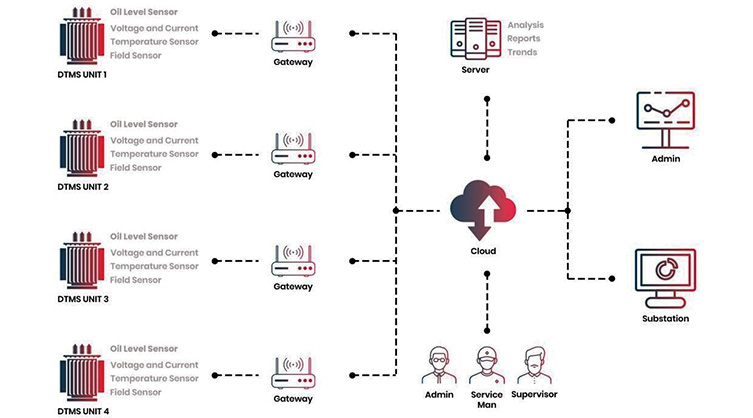

Solution: Implementing an Intelligent Transformer Monitoring System comprising IoT Gateway, Sensors, and CMS (Central Management System) to provide real-time data for predictive and preventive maintenance of transformers.

Outcome: • Reduced maintenance cost • Enhanced service life of transformers • Improved Asset Monitoring and Asset Optimisation

Summary: The Gujarat Power Research & Development (GPRD) sought a comprehensive system to monitor key transformer parameters. The desired solution would read digital and analogue signals from the transformer, process them at the central management level, and provide valuable insights to the Asset Manager for efficient transformer functioning. The client required a complete system with sensors included. We successfully monitored the LV side lug temperature, especially during summers, to predict potential risks of transformer burning.

Client Profile: The Gujarat Power Research & Development (GPRD) Cell is a prestigious research centre established by the Government of Gujarat to serve Gujarat Urja Vikas Nigam Limited (GUVNL) and its subsidiary companies, including GSECL, GETCO, DGVCL, MGVCL, UGVCL, and PGVCL. Operating under the umbrella of Gujarat Urja Vikas Nigam Limited (GUVNL) and supported by the Government of Gujarat, GPRD plays a crucial role in advancing power-related research and development initiatives in the state. GUVNL is the parent holding company for GSECL, GETCO, DGVCL, MGVCL, UGVCL, and PGVCL. Each of these companies contributes to the energy sector in Gujarat, with GSECL focusing on electricity generation, GETCO handling transmission, and DGVCL, MGVCL, UGVCL, and PGVCL managing electricity distribution, operation, and maintenance up to the consumer level within the state.

Business Challenge

GPRD faced a significant challenge without a real-time monitoring solution for transformers. Relying on traditional field visits to assess transformer status proved inefficient and outdated. Moreover, on-site personnel had to carry various instruments to measure key electrical parameters, such as voltage, current, harmonics, oil level, oil temperature, LV Lug temperature, phase angle, power factor, and energy consumption. This approach often led to skill-related issues among the site personnel or the unavailability of necessary measuring instruments, resulting in time-consuming processes.

The Solution

GPRD turned to System Level Solutions (SLS) to address these challenges, renowned for its successful track record in providing products and solutions for industrial applications. SLS designed and implemented a cutting-edge Real-Time Transformer Monitoring System (TMS) tailored to GPRD’s requirements. The TMS allows precise measurements of various electrical and physical parameters, including three-phase voltage and current, frequency, phase angle, active power, reactive power, apparent power, energy consumption in the last 24 hours, power factor, voltage THD, current THD, graphical representation of voltage and current harmonics up to 60, phasor diagram, LV side lug temperature, oil level monitoring in the conservator tank, primary tank oil temperature measurement, graphical representation of real-time and historical data, and prediction of abnormal transformer conditions.

Moreover, the TMS incorporates an alarm and fault management system, ensuring prompt identification and resolution of potential issues, thus enhancing the overall efficiency and reliability of transformer monitoring.

The Real-Time Transformer Monitoring System developed by SLS represents a significant step forward for GPRD, providing a reliable and comprehensive solution that streamlines transformer monitoring, enables data-driven decisions, and ultimately enhances the performance and longevity of the electrical infrastructure in Gujarat.

TMS solution consists of TMS Hardware, TMS Firmware, TMS Sensors and CMS TMS HardwareThis unit consists of a metering chip and a communication module. It has an internal ADC to support field functionalities and sensors. It supports GSM, Bluetooth, RS485 and Ethernet interfaces based on specific requirements. It also has two channels for potential free contacts (DO); four channels of optically isolated digital input for 24V; four temperature channels; four 4 to 20mA channels; few indication LEDs at the front side of the unit; provision for Li-Ion battery for 4 hours of battery backup.

Field Sensors

This unit consists of various field sensors like flexible Rogowski coils as a current sensor; oil level sensor; temperature sensors; oil temperature sensor; ambient temperature sensor.

TMS Firmware

TMS firmware is developed for measuring energy parameters, monitoring field sensors, and regularly sending all the measured data to the cloud. Data collection, validation, and arranging in a suitable format are one of the most important functions that the firmware serves. The firmware handles various arithmetic and logical operations corresponding to the energy data, like over-voltage, overcurrent, phase imbalance, etc. It collects unit-level information and processes it based on real-time operational requirements. It also communicates with the TMS mobile application, ensuring easy and interactive data transfer at normal operation and maintenance modes. It monitors communication happening with the cloud.

Central Monitoring System (CMS)

A CMS integrates all the data and represents it on a single user-friendly dashboard.

Outcome

With the solution, the client monitored multiple parameters within a fraction of the time and presented them in a user-friendly form, even in a harsh environment. Each transformer used in the power plant has a different type and number of sensors which made the client configure hardware and software according to the requirement without any further dependency on a third party for modifications.

With the Intelligent Transformer Monitoring System (TMS) the client was able to find ways to reduce maintenance costs and increase the service life of the transformer. Moreover, they could also optimise transformer performance and identify faults at any stage and location.

For more details, visit: www.slscorp.com

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.