Live-line working for transmission and distribution systems

By EPR Magazine Editorial May 5, 2020 1:07 pm IST

By EPR Magazine Editorial May 5, 2020 1:07 pm IST

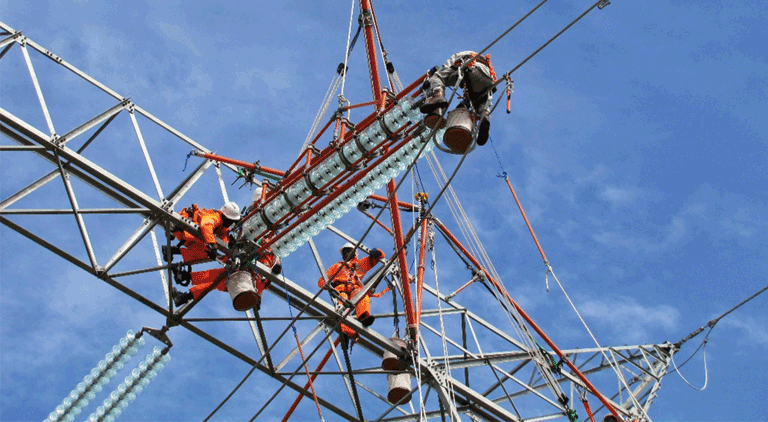

Live-line working or hotline maintenance involves maintenance, repair or replacement activity carried out on a live and operational line or switchyard apparatus using approved techniques and equipment. It is the preferred method of maintenance where system integrity, system reliability, and operating revenues are at a premium and removal of circuit is not acceptable.

Need of live-line working

To evade the necessity to shut down electrical networks for maintenance services, it is mandatory to develop safe and practical techniques that would allow continuous electrical power supply, thereby reducing the risks and minimising the costs for the transmission and distribution companies. Live-line maintenance is a comprehensive solution to restrict outages and breakdowns substantially by systematic implementation of condition monitoring and preventive maintenance schedules with appropriate use of human resources and machinery.

Major benefits of live-line working are listed below:

Progress of live-line working in India

Historically, live-line technologies in India were introduced since the 1960s, where limited maintenance on energised lines was performed by the hot-stick method up to 220 kV. After the introduction of the bare-hand technique of live-line maintenance in the 1990s, some maintenance activities were expanded on 400 kV lines by a couple of utilities. However, we have seen a real boost in live-line working in India since 2005 after the introduction of insulated modular scaffolding system and puncture insulator detectors, and supply of customised tools suitable to customer’s requirement, providing technical assistance to utilities. Presently, we have achieved live-line working up to 765 kV level and introduced insulated aerial work platform on par with western countries.

Condition monitoring

Although visual inspection of transmission and distribution lines provides flashover or broken insulators’ data, the internal puncture phenomenon could not be recognised by such conventional methodology. A microprocessor-based Puncture Insulator Detector (PID) identifies all such invisible problems with computerised graphical output for every type of insulators such as porcelain, glass or polymer. This PID equipment is useful for different types of lines and switchyards. There are other live-line condition monitoring techniques available such as fault passage indicators for distribution lines and inspection of energised electrical joints and line conductors, etc.

Live-line working methods

Hot-stick or distance technique consists of an insulated glass stick to protect the line worker from a grounded source while working on live lines. Generally, this technique is suitable and widely adopted up to 220 kV potential.

Bare-hand technique permits linemen to be in direct contact with potential, being insulated from the grounded object. This live-line methodology is used above 132 kV level and up to 800 kV.

Rubber glove or contact method is a technique in which the person is fully insulated from the ground through an insulated elevated platform and performs live-line work using approved insulating gloves and sleeves. This technique is useful only for distribution networks up to 46 kV.

Live-line work on transmission lines

Entire routine maintenance activities such as insulator replacement on suspension and tension towers, on-load tightening of clamps and connectors, strengthening of dead-end joints, replacement of jumpers and mid-span joints, line conductor repairs, insulator hardware maintenance or replacement are possible by suitable hot-stick or bare-hand technique with appropriate live-line tools and equipment.

To maximise the output of a live-line crew working on high-voltage transmission lines, systematic application of vehicle mounted insulated aerial work platform will be highly beneficial as it will directly launch linemen on energised conductors and thus prevent the unnecessary task of climbing towers by linemen. Specially designed conductor trolleys for bare-hand technique are helpful for linemen to work on energised conductors with increased safety and efficiency.Live-line work in EHV switchyards

With the help of insulated modular scaffolding system, maintenance activities in switchyards up to 765 kV have been completely redefined. Activities such as hotspot rectification, jumper replacement, maintenance of isolator switches, clamps and connectors are being performed with great safety and reduced efforts. With an advanced set-up of multiple scaffolding systems, live-line crews able to replace isolator switches and busbar tubes in extra high voltage switchyards. Replacement of lightening arrester and working on high-voltage line traps are now possible with the introduction of on-load temporary bypass switch. With some specialised insulated forklift attachment, one can replace heavy support insulators in high-voltage energised switchyards.

Live-line insulator washing

Now indigenously developed live-line insulator washing equipment armed with twin high-pressure jet washing guns up to 800 kV lines are available to fulfil complete requirement of utilities for transmission or distribution lines and switchyards. Insulator cleaning is highly beneficial and recommended where the pollution deposition is high, particularly in coastal and industrial areas. If the deposited pollutants increase above a certain predetermined level, insulator flashover will happen, which is a very costly affair. By implementing periodic insulator washing cycles, utilities have experienced minimal or zero interruptions.

Live-line work on distribution lines

Although we have achieved the feat of live-line working on transmission lines up to 765 kV, live-line working on distribution lines has been highly negligible so far. A couple of utilities used to work on distribution lines but were limited to few areas due to conventional methods. Except tree trimming, systematic preventive maintenance activities could not be possible due to direct interruptions to the highly paying commercial and industrial consumers and there is no other way than breakdown maintenance.

Therefore, this picture of breakdown maintenance must be transformed to preventive maintenance and live-line working will play a very important role here. With the help of aerial work platform and rubber glove technique, we can perform all the uninterrupted maintenance activities on distribution lines like change of pin or disc insulators, hotspot rectification, conductor or jumper repairs, and tree trimming up to the extreme pole replacement in energised conditions.

Safety during live-line work

By following safe work procedures defined in various manuals, regulations and standards and use of pre-service equipment like hot-stick, rope and conductive suit tester, proper cleaning and conditioning of live-line tools and equipment and in-service leakage current monitors, etc., safety during live-line working can be fully achieved. Alternatively, risk of back feeding or accidently charged circuits, particularly in case of distribution systems, has been completely eliminated while performing live-line working.

Conclusion

By overseeing the major expansion of the transmission and distribution system and with growing entry of private players in the power sector during recent years, every utility shall look forward and adopt the modern techniques of maintaining the T&D system to put at par with the global trend of maintenance techniques. The adoption of live-line working technology will definitely reduce interruptions and increase the availability of the T&D system which is vital to generate more revenue.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.