Robust power sector pushing growth of power transformer market

By EPR Magazine Editorial March 27, 2020 4:01 pm IST

By EPR Magazine Editorial March 27, 2020 4:01 pm IST

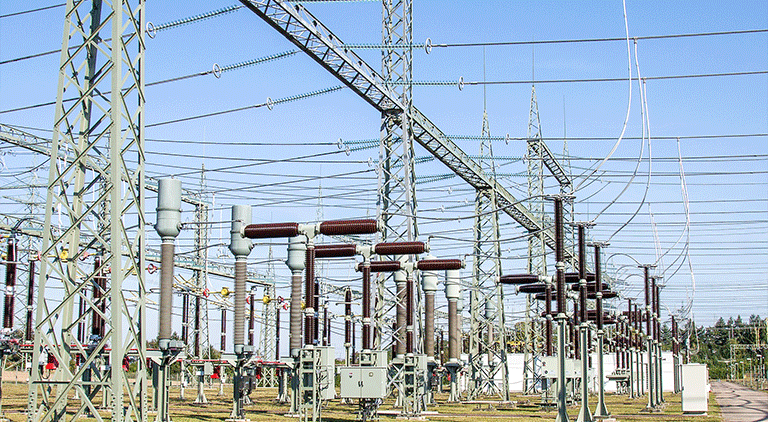

Favourable reforms and rising power consumption are the major factors driving the growth of India’s power transformer market. We take a look at the other causes of market growth and how companies are participating in this growth.

The Indian power transformer market is set to witness an upswing due to an increase in electricity consumption and favourable regulatory reforms by the government and is expected to reach $2.9 billion by 2022. The surge in power demand has been fostered by an increase in capacity utilisation, industrialisation, urbanisation and population. New technologies, materials and practices are set to drive this growth further. We look at the factors contributing to market growth in detail and the technological innovations that we can expect to see in the near future.

Harnessing the benefits of recent growth in transformer market

With the above factors pushing market growth, it is imperative for companies in the segment to take advantage of the growth factors and use them to their benefit in order to keep up the momentum. Atul Agrawal, MD, Uttam Bharat Electricals Pvt. Ltd. says, “In order to be part of the growth momentum, we are aggressively working on technological and capacity expansions. Our strong sales and marketing team is continually working on expanding our geographies both in the domestic and international market. The power sector is extremely robust with an increase in demand for electricity. As renewable energy and sustainability are becoming the need of the hour, our company is gearing up to focus more on solar energy. Through these initiatives, we plan to contribute to the growth of the Indian transformer industry.”

N.K. Duggal, GM (Marketing), ABC Transformers, informs us, “We make multi prototype products and strictly adhere to the set standards and specifications. We get references from the industry and also repeat orders from our customers. Our old customers still partner with us because of our excellent quality. We cater to new transformers too and get new tenders. Consumers are now more aware of the products they are buying, so they want good quality products that meet their demands. They are ready to pay the right price for the product.”

Narendra Goliya, Director, Rishabh Instruments Pvt. Ltd. says, “All power and distribution transformers need measurement, not only basic parameters like voltage, current and active/reactive power but also advanced parameters like tap position, oil temperature, electrical disturbances like swivels, dips and transients to ensure continuous operation of the transformer. These measurements can be used both for predictive failures and for post-failure analysis depending on the software installed. Rishabh is in all these fields including data on the cloud.”

Development of technologies and insulation materials for transformers

Laser scribing technology was introduced about 25 years ago. The main purpose of this technology was to reduce the eddy current component of the core loses. Through laser scribing, small domains were created on the core laminations. In this way, the resistance to eddy current was increased and thus the I2R losses were reduced. Agrawal discusses, “The etching or scribing was initially done by drawing physically visible parallel lines. This affected the overall stacking factor badly. Nowadays such domain defining is being done using laser rays which do not affect the physical dimensions and hence the stacking factor is not affected adversely. But there are limitations in such laser scribed laminations as the annealing process nullifies the benefits obtained due to laser scribing. However, in the present scenario, laser scribed CRGO is available where annealing after processing of the lamination is possible. Further, the laser scribed lamination poses the same challenges while using these materials for wound core construction.”

With regards to technologies for better safety of transformers, Jitendra Agrawal, Managing Director, The Motwane Manufacturing Company Pvt. Ltd. tells us, “We have a very large fleet of assets and distribution networks. The first and foremost is to maintain the assets. The traditional maintenance practices would require huge investment of manpower, money and time, making it highly inefficient and unproductive due to requirement of prolonged duration of shutdown. It is time to use the modern method of need-based maintenance practices by deploying real-time monitoring of transformers and analysis of historical records of asset health parameters.”

Goliya adds, “With the vast amount of transformer failures, cost of downtime and technologies available in today’s world, it is imperative to understand all the failures, have continuous monitoring of these parameters and alarms set up so that there is a predictive signal to the user to avoid the failure.” Failures could be simple overloading, either continuous or intermittent; deterioration in the quality of oil; excessive current and/or voltage harmonics in the system; too much of reactive current; and deterioration in the insulation resistance of the windings. All these can be continuously monitored and data be taken to a cloud to give appropriate alarms to mend these in proper time.

New insulation materials are also helping transformer companies create better quality products that meet the high safety standards of the industry. Insulation systems in power transformers consist of a fluid — either liquid or gas — together with solid materials. The solid insulation and oil form an inseparable insulation system in a transformer. Insulation in transformers mostly comprises paper wrapped around the conductor in transformer coils, mineral oil and pressboard. One basic requirement of all insulating materials is that they should be compatible with the insulating oil and should not react with it.

Agrawal elaborates, “Paper is a low-cost base material with strong mechanical and electrical properties. But due to variety of factors including temperature, paper can substantially lose its properties, thus affecting the service life of a transformer. To substitute, the so-called thermally upgraded Kraft papers/diamond dotted Kraft are made for covering the conductor with high thermal index and mechanical strength. These types of papers help in maintaining insulation property even at a higher temperature. The other new insulation material used in transformer is ester oil. Ester oils have a high flashpoint temperature and excellent biodegradability.”

Jitendra discusses, “Power transformer design has already matured to deliver maximum efficiency. The technological innovations are largely concentrated in improving the reliability of the transformer by minimising the chances of breakdowns and failures.” There are two approaches to tackle this issue: online condition monitoring of the transformer, and use of different insulating medium. Based on the choice of medium used for insulation, there are two innovative designs, i.e., Dryformers and gas-insulated transformers (GITs).

Latest innovations in power transformersJitendra states, “Investment is required in innovative solutions for monitoring various critical assets like transformers, reactors, switchgears, etc., which enhance the reliability of operations of the assets.” He adds that investment in various material technologies to improve asset stability and extend the range of the operation and life of assets, as well as investment in power storage technologies like batteries and inverter technologies are also essential.

With increasing power and voltage ratings of transformers, the technological leap will continue to grow in the coming years.

N.K. Duggal, GM (Marketing), ABC Transformers

Consumers are now more aware of the products they are buying, so they want good quality products that meet their demands.

Atul Agrawal, MD, Uttam Bharat Electricals Pvt. Ltd.

Though there has been no significant change in the type of winding conductors used in power transformers, we can see a steady development of core steel materials from non-oriented steels to scribed-grain oriented steels.

Jitendra Agrawal, Managing Director, The Motwane Manufacturing Company Pvt. Ltd.

The technological innovations are largely concentrated in improving the reliability of the transformer by minimising the chances of breakdowns and failures.

Narendra Goliya, Director, Rishabh Instruments Pvt. Ltd.

With the vast amount of transformer failures, cost of downtime and technologies available in today’s world, it is imperative to understand all the failures, have continuous monitoring of these parameters and alarms set up so that there is a predictive signal to the user to avoid the failure.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.