Steaming the corrosion away

By EPR Magazine Editorial February 7, 2019 5:28 pm IST

By EPR Magazine Editorial February 7, 2019 5:28 pm IST

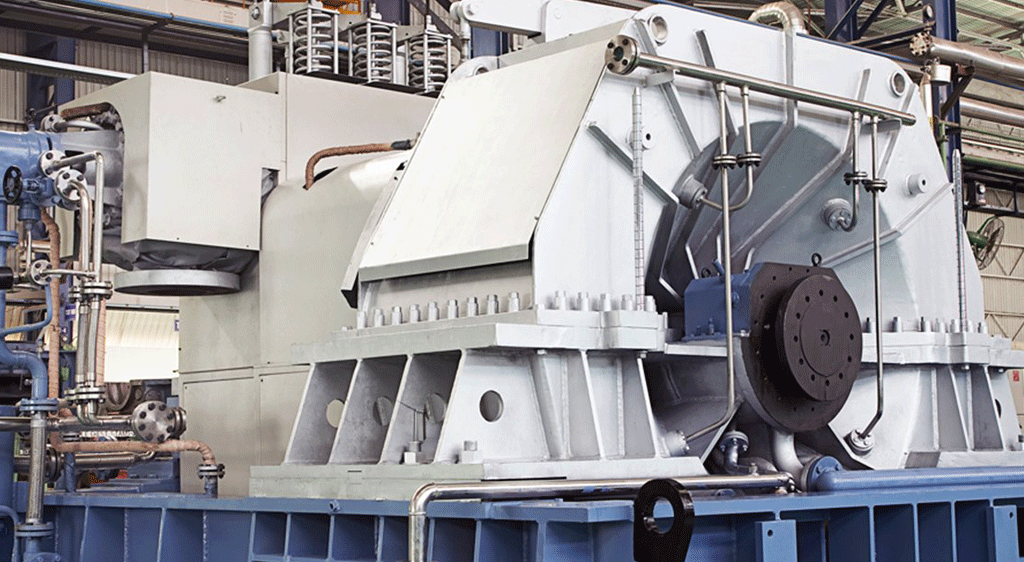

The steam turbine is a highly efficient product that is used for converting large amounts of heat energy into mechanical energy. As the steam expands, enthalpy of the steam is first converted into kinetic energy in nozzles or blade passages and it acquires high velocity and exerts force on the turbine blades and power is developed due to rotation of the blades.

Efficient and meticulous design of blade profile combined with advanced aerodynamic designs aimed at reducing energy losses is integrated into the turbine for extracting maximum energy from the steam.

Corrosion damage be handled in steam turbines

A steam turbine faces the worst possible environment regarding corrosion. This is due to the working conditions of a normal steam turbine, which are high temperature, constant contact with water and air, and high probability of facing concentrated chemicals due to evaporative concentration in the boiler.

Turbine corrosion is dependent on a combination of environmental aspects such as steam chemistry, temperature, stresses, material properties, composition, and defects. Even pure water and wet steam can causes corrosion of turbine materials, chiefly in the rotor and disc parts.

Authored article by:We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.