Adoption of better safety standards, materials is key for healthy earthing system

By EPR Magazine Editorial November 26, 2021 3:53 pm IST

By EPR Magazine Editorial November 26, 2021 3:53 pm IST

This article explains how complying to the international safety standards, along with implementing technologically upgraded materials will minimise safety risks of an earthing system.

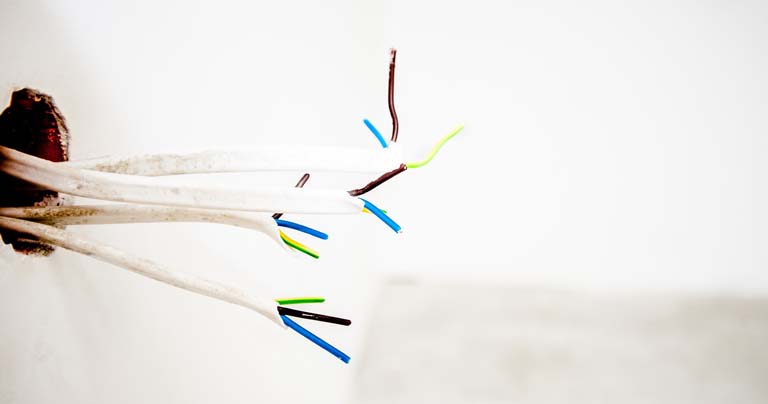

Earthing systems are one of the critical aspects of an electrical system. The ever-increasing demand for electricity has been transforming the outlook for electrical and earthing safety in an electrical unit or an electrical system. Appropriate installation of earthing applications enables us to ensure that the potential of a conductor carrying current remains to be constant. To be more specific, quality earthing systems and installation will enhance electrical safety.

Technological changes impacting the demand for an earthing system

Since its inception, there have been many changes in the earthing and lightning protection industry. Initially, salt & charcoal were the principal agents in the earthing system.

According to Kanderp Khandwala, Co-Founder & Managing Director, Axis Electrical Components (I) Pvt. Ltd. “The technology has moved us from salt and charcoal to copper bonded earth rods. Technology advancement concerning testing has evolved from no testing or maintenance to imposing strict policies for testing and maintenance. The demand for earthing systems, have seen 6-8 percent growth annually across India. Nowadays, the lightning protection system, supply system, and equipment earthing is identified, calculated and designed as defined in the standards.”

According to K. Arul Prakash, Managing Director, OBO Bettermann India Private Limited, “Increased awareness on overcoming challenges with advanced methods of earthing installation is helping the longevity of earthing systems. Proper understanding of latest standards and using products complying with the requirement of international standards will increase the efficiency of the earthing system to manifolds.” A classic example is the old pipe earthing with salt and charcoal are being gradually replaced with copper bonded earth electrode following guidelines of IEEE and IEC standards.

According to Priyank Verma, Director, Earthing Solutions Pvt. Ltd. “Earthing (grounding) is older than electricity itself. No matter what technological developments are made, grounding will be essential for product and life safety. With further developments, products are getting more sensitive to electrical faults. This calls for better and more efficient grounding systems to ensure complete safety of product and life.”

Selecting an earthing system

Over the number of years, the criticality of earthing is now well understood, and due importance is given to service as it is the heart of the system.

Noting the same, Kanderp explains us the three main aspects that one needs to keep in mind. Soil resistivity, System fault level and effective resistance allowed as per standards. The system earthing, body earthing and neutral earthing is calculated and designed accordingly.

Whereas, Arul highlights that before we select an earthing systems we must comprehend and understand the purpose and the design life of an earthing system. Post, we should look at the soil resistivity, soil’s corrosive nature, shape and available area to place the system and its seasonal variation.

“At ES we follow the PADE approach while consulting our clientele in selecting a suitable grounding system. Product, assessment, design and execution are four pillars of PADE which enable us to recommend the best possible products”, says Priyank. All other aspects such as Load Capacity, Type of Load, Range of Fault Current, Location, Soil Resistivity, Soil Condition, Power Line, etc falls under PADE.

Materials to reduce failure

Various international standards BS 7430, UL 467, IS 3043, IEEE 80, etc. have elaborated on design principles for Earthing. The earthing data is logged and kept in check to avoid or prevent a fault. “Earthing materials have evolved from salt and charcoal to environmentally friendly earth enhancing compounds. It ensures an extended life for earthing systems, less corrosion and better resistivity and the new generation earthing materials are not leachable, hence making them maintenance-free with better life,” says Kanderp.Proper functioning of earthing system depends on the selection of material, suitability of installation, compliance to test criterion mentioned in National / International Standards. As earthing is a passive component there shall not be any failure, however flaws in achieving value shall be avoided by measuring soil resistivity and designing required quantity of earth pits. “We at OBO measure soil resistivity, design required earth pits with the help of a proven software and provide suitable materials required for the soil condition” says Arul.

“ES believe every component make the entire product great. Electrode, chemicals, accessories all make up one remarkable product. Every day we hustle on every aspect of them to develop our products”, explains Priyank.

Enhancing the safety of electrical products

As mentioned above, people have moved away from materials like salt and charcoal that would cause a decrease in the life of the earthing system. “Now environmental friendly materials, non-leachable, nontoxic materials are in use. Along with the upgraded materials, more efficient ways of installing earthing have also positively impacted the safety of electrical products,” explains Kanderp.

Arul on the other side feels that an eco-friendly and safe Earthing system can be achieved by following the latest standards and fulfil the test requirement as per IEC 62561 in terms of non-toxic, leaching characteristics for compound and also humidity and salt mist test for electrodes.

Nothing the safety aspect, Priyank adds that ES advocate and practice sustainable and eco-friendly approach at every step of the way. Our chemicals include complete eco-friendly components as well. We firmly believe that with our intention to make our existence sustainable, we will achieve that in very near future.

Available earthing solutions

Axis is promoting all types of Earthing and LPS design systems. We are promoting structural earthing for better protection & life. Additional to the new stainless steel product range in earthing and lightning protection solutions, we are also launching our LPS design software. The Axis software provides you with a Step-by-Step Guide to Earthing and Lightning Protection Design.

OBO Bettermann is the only company in India offering the complete electrical infrastructure solutions for any type of Buildings. This provides our customers with an unique advantage of getting their complete electrical infrastructure solutions from one source.

ES is home to more than fifty two range of products and services in providing solution for lightning protection, surge protection and grounding, which help us in being the partner in safety of our clientele. Our product and service range consists of New Generation Lightning Protection System, Conventional Type Lightning Protection System, Maintenance Free Grounding System, Surge Protection Devices, Project Consultation, Audit & Maintenance, etc.

The way forward

With the most widest range of products available in our Lightning, Surge protection and Earthing systems portfolio we have been always a preferred choice for almost all customer segments in India.

We will remain focussed on offering our customers with the best of solutions as per the latest National and International standards. Our endeavour is to ensure we offer value for the trust being bestowed on us.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.