Features of plate earthing diagram – explained

By EPR Magazine Editorial November 14, 2021 11:04 am IST

By EPR Magazine Editorial November 14, 2021 11:04 am IST

Electrical earthing is the phenomenon of connecting metallic parts of an electrical component to the earth.

Earthing is the connection of all the neutral points present in the supply of the system to create immediate discharge of the electrical energy during a fault without any danger. Earthing provides an alternate path for the fault current to flow and ensures that all the exposed conducting materials do not reach their respective maximum potentials.

A good earthing system always has low impedance to make sure that sufficient current can flow through the safety device and disconnects from the supply during the occurrence of fault current. A good earthing system protects the personnel against electric hazards and safeguards electrical devices, appliances, power tools, machinery, etc., from current leakage. Properly designed earthing also avoids interference with the communication circuits present in the system. There are many types of earthing systems which include plate earthing, pipe earthing, rod earthing, and chemical earthing.

Plate Earthing: In this type of earthing, a plate made up of galvanised copper or iron is buried vertically at a depth of not less than 3m from ground level. The plate connects all the conductors to the earth.

Pipe Earthing: In this type of earthing, a galvanised steel perforated pipe is buried vertically connecting all the electrical conductors to the earth where the depth of the pipe depends on the soil conditions. Pipe earthing is an economical type of earthing compared to other earthing methods.

Rod Earthing: In this method, a copper rod of 16mm diameter and galvanised steel or hollow section of 25mm is buried vertically at a depth of not less than 2.5m. This resembles an embedded electrode which reduces the earth’s resistance to the desired value. The procedure implemented for rod earthing is similar to that of pipe earthing.

Chemical Earthing: In this type of earthing, a chemical compound material is applied to the charcoal and salt layers and buried inside the earth. The procedure for implementing this method is also similar to pipe earthing methods.

Different factors are to be considered for choosing the type of earthing applied such as safety requirements for humans and equipment, maintenance of the equipment, economic considerations and the continuity of supply at different voltage levels and eliminate dangers from threats and hazards.

Below mentioned are a few applicable standards that are followed throughout the execution of the earthing system:

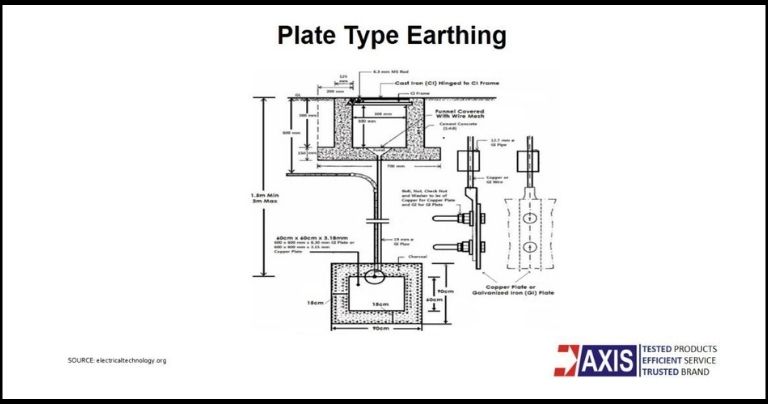

To implement a plate type earthing, a plate made up of either copper or galvanized iron (GI) with dimensions 600mm x 600mm x6.35mm is buried vertically in the earth which is not less than 3m from the ground level. For successful completion of the plate type earthing, an earth pit must be dug, plate electrodes should be inserted, earthing and water connections are to be made, the pit must be backfilled and an inspection chamber should be built. The plate type of earthing is generally carried out in a muddy area where the most percentage of the earth’s soil is loose.

Earth Pit: Excavation is done at a feasible spot in the substation and an earth pit of minimum size 900mm x900mm and a depth of 3m below the surface is created.

Plate Electrode: A GI plate of minimum size 600mm x600mm and thickness of 6.3 mm is used and in the case of a copper plate a minimum thickness of 3.15mm can be used. The plate is placed in such a manner that the earthing plate is surrounded by an alternate layer of charcoal and salt.

Earthing Connection: In an earthing connection a GI strips of a minimum 50mm x 6mm to GI plate firmly with a GI nut, bolt and washer where each strip is fixed and welded to the plate at two different locations. These connections are made stronger as any loose earthing can lead to an adverse effect on the electrode system resistivity.

Water Connection: To maintain moist conditions around the earth plate, a fixed GI pipe of diameter 25mm is attached at the top covered with a wire mesh and water is poured through this pipe after which the excavated pit is backfilled with soil which is free of stones and lumps.

Inspection Chamber: A brick chamber is built around the earth pit over a P.C.C layer of size 450mm x 450mm x 450mm with a thickness of 100mm placed at 100mm above the ground level where the top cover is placed with cast iron (CI) hinges to CI frame.

There are different steps to be taken before installing an earthing system to follow the approved design and drawing or laying of the earth wires between the electrode and the electrical room are as follows; There are numerous applications of plate type earthing such as telecommunication, transmission, substation and power generation, transformer neutral earthing, lightning arrestor earthing, equipment body earthing, water treatment plants, heavy industries, college, hospitals, banks, residential buildings, etc.

Conclusion

Electrical earthing is the phenomenon of connecting metallic parts of an electrical component to the earth. Earthing always minimises the danger of discharge of electrical current which is designed using various earthing standards such as IEEE, IEC, NEC, ANSI, IS, etc. different standards are used for different occasions. Earthing a live wire would lead to a catastrophic disaster. Earthing can also improve the lightning protection systems. Plate earthing can prevent major accidents such as accidents that occurred due to static charges and stray current and protect systems like central communication, electronic and AC power systems meeting the earthing safety requirements for the electrical substation.

At AXIS, we test our products following major international standards such as IEC, BS EN, UNE, and UL & IS. We also provide design solutions including proprietary risk assessment software complying with IEC 62305 -2.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.