Modernisation of power distribution assets with Smart Retrofit

By EPR Magazine Editorial March 4, 2022 6:51 pm IST

By EPR Magazine Editorial March 4, 2022 6:51 pm IST

This article briefly discuss the technical aspects of switchgear and IoT enabled smart retrofits to deal with frequent machine downtime and offer efficient power distribution

Present Scenario

Power distribution is the lifeline of any industry or infrastructure, however most often it is neglected. Generally, it is fit and forgets. Not focused in terms of upgrades or modernisations, as power distribution assets are considered unproductive.

Throughout the world there are, many old, low voltage products protecting essential industrial processes that have been operational for a significant time-period ‘beyond’ their functional design life. Any such product that has been in service for this period will either be very close to the end of its useful working life or worst, beyond it.

Main challenges with this older power distributions system are:

Ageing: Due to end of its electrical/mechanical life, it will have less efficiency.

Un-available data: No trip history available.

Fault Diagnosis: Not easily possible.

Expertise: Very limited expertise in market to repair these old products.

Spares: Very difficult to obtain spares. Costs: Higher maintenance cost for frequent repairs and costly spares.

Downtimes: Higher downtimes required even for complete system/product replacement. Budget: Higher budgets required for complete system/ product replacement.

Safety: Extremely un-reliable for system and during human operations.

Frequent Faults: Faults like nuisance tripping, over temperatures can occur resulting in frequent breakdowns.

Conventional Approach

Conventional Approach

Many retrofits are mostly reactive and focused only after end of its products life cycle, which results in frequent breakdowns, higher downtimes. This further becomes a threat to entire system in terms of safety.

In most cases, customers take a lot of efforts based on their best knowledge to keep the plant running without breakdown. Like by keeping the panel door open, putting extra fan for air circulation in power distribution panel, which doesn’t solve the problem permanently, eventually leading to flashovers.

Although it looks very appealing to go for retrofits, customers should be very cautious while selecting new appropriate replacements and while retrofitting, detailed execution plan to be implemented in line with all prevailing safety standards.

Although it looks very appealing to go for retrofits, customers should be very cautious while selecting new appropriate replacements and while retrofitting, detailed execution plan to be implemented in line with all prevailing safety standards.

Hence it is highly advisable to avoid un-reliable market retrofitting solutions, which may temporarily give results, but fails in long run.

Solution

Hence, it is prudent to have more proactive and SMART holistic approach for retrofits.

Main components of SMART retrofits are:

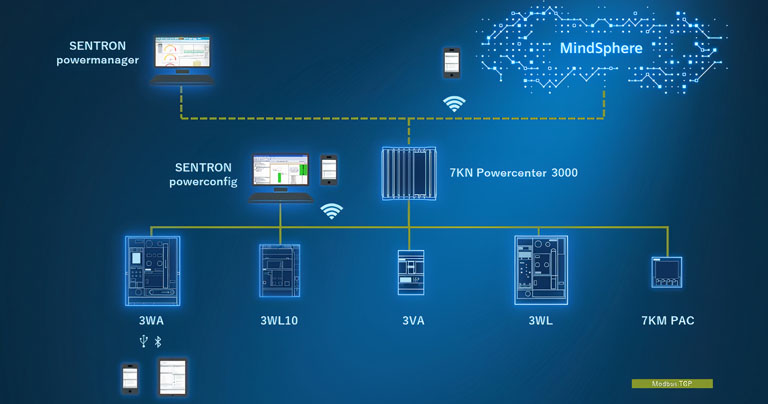

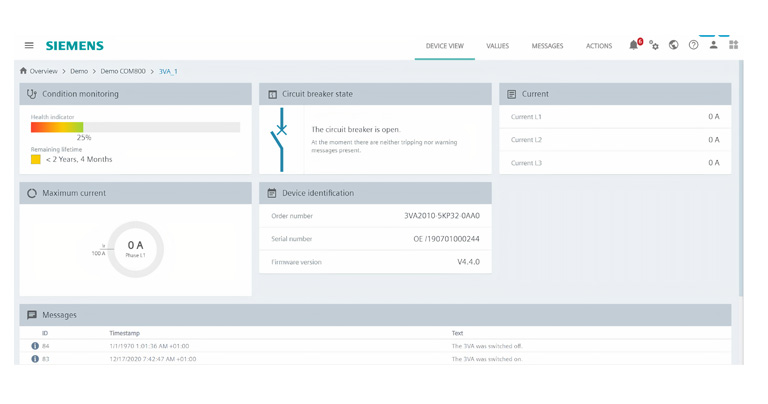

Product Retrofit: It can be considered when all other systems components are having further life and by implementing perfect engineered solution of factory tested RETROFIT KIT and also by including cutting edge products like IOT enabled breakers etc. switchgear system becomes DIGITAL panels which facilitates in easy integration with existing DCS.Sharing diagnostic information like terminal temperatures, currents, and all events data through web access/built in web server will not only be monitored but also actions can be configured like switching OFF while exceeding threshold values etc., to avoid unplanned breakdowns.

Getting diagnostic data for predictive maintenance on HMI, Mobile or TAB

System Retrofit: It is advisable when entire system life has ended or while upgrading to new technologies like IMCC’s which offers higher productivity

Benefits of Smart Retrofits

If planned and carried out as a design exercise, the retrofitting can prove to be a cost-effective solution for both, maintenance engineers and site managers, especially on facilities where down time must be kept to an absolute minimum.

Apart from addressing above challenges with older products, following are the added advantages*

Certification: All news products are with latest IEC/IS standards.

Compact: More compact when compared to older products.

Specifications: Higher specifications are possible within same product range.

IOT Ready: All new products are IOT ready in line with emerging technologies:

Operations: Remote operations are easily possible

Asset Management: Lower operating costs Cloud Connectivity: Multi location feeders can be commonly viewed in a single page

Data Analytics: By using AI/Machine Learning techniques, forecasting of faults is possible

Easy Maintenance: With in-built microprocessors, new products can self-check their healthiness regularly and can give maintenance alerts including remaining life time.

SMART RETROFITS can add substantial value to the integrity of the low voltage installation making it a DIGITAL SWITCHBOARD

Siemens provides end-to-end digital retrofit solutions right from panel feasibility study to complete retrofit execution.

Expertise shared by:

M Santhosh Kumar Raju, Manager – Customer services, and

Ram Ballabh Sinha, Head-Customer Service,

SIEMENS LTD.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.