Efficient water solutions to drive growth of pumps and valves market

By EPR Magazine Editorial June 11, 2020 5:43 pm IST

By EPR Magazine Editorial June 11, 2020 5:43 pm IST

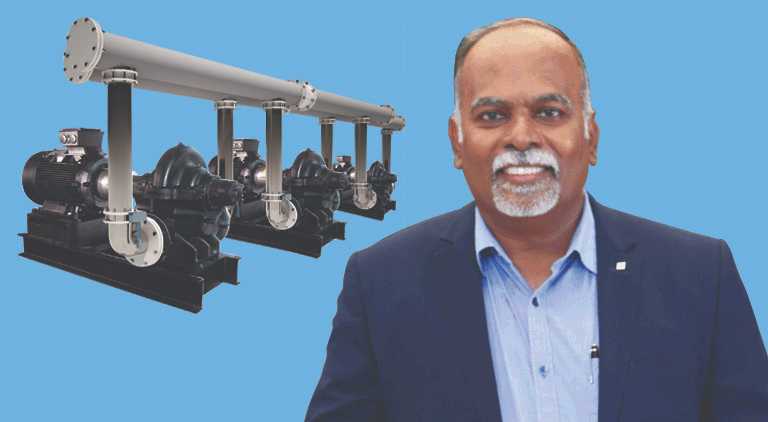

Saravanan Panneer Selvam, General Manager, Grundfos India talks about the latest innovations the company has developed to enhance pump systems, and how intelligent solutions facilitate remote process monitoring on a real-time basis, thereby reducing the need for human intervention.

Please elaborate on the company’s noteworthy offerings including innovations and digitalisation.Grundfos was the first company to bring in electronics to pumping solutions way back in 2007. Currently, our electronic pumps or E-pumps are equipped with integrated controls that help our solutions adapt to changing demands. Their frequency converter ensures that the pumps are significantly more energy-efficient with optimised performance capabilities. Innovation is a part of our DNA and our endeavour is to consistently improve the energy efficiency of our solutions. For example, our MAGNA3 solution has an unmatched Energy Efficiency Index (EEI) in comparison to our counterparts in the industry.

What kind of latest technologies are being implemented in your products to increase efficiency and ease the water processing system?

Powered by our deep understanding of the nexus between water, energy, hydraulics, and digitalisation, Grundfos iSOLUTIONS utilises intelligent pumps, cloud connectivity, and digital services. Together they enable real-time monitoring, remote control, fault prediction, and system optimisation to help customers reach a new level of performance and efficiency. Grundfos iSOLUTIONS brings a new era of intelligence to pump systems and water technology with solutions that look beyond individual components and optimise the entire system, making them more energy-efficient as well.

There are concerns of water being wasted during the transit process in pipelines. How are your pumps and valves helping to minimize water wastage?

In India, 30–70 percent of piped water is wasted through leakages as non-revenue water during the distribution stage. These leakages can be primarily attributed to pressure built up in the pipes. As a trendsetter in water technology, Grundfos has introduced the Demand Driven Distribution (DDD) to tackle this concern by intelligently managing water pressure in the pipes based on the load in the system. DDD has been successful in reducing water leakage by almost 20 percent as it adjusts surplus water pressure and minimises the possibility of ‘water hammer’. Since the water pressure is maintained only at the optimum level and not at the maximum level most of the time, the life of the pipes is also enhanced. This positively impacts the overall life cycle of the system and decreases the need for human intervention to monitor the pressure.

What are the growth opportunities and challenges in the domestic pumps and valves sector?

With the increasing demand for highly efficient water solutions, the pumps and valves industry are witnessing immense growth and potential for further development. Their growing presence and need in urban areas can be attributed to booming infrastructure projects and smart cities. In residences and commercial buildings, their applications include but are not limited to pressure boosting, water distribution, heating, cooling, and wastewater handling and treatment.

The pump industry, including the domestic market, is also witnessing an influx of counterfeit products. It is now up to the customer to understand the efficiency, cost savings and other benefits in the long run while making their purchase. In other words, the life cycle cost of the pump should be given more importance than the initial investment alone.

What is the future outlook for the sector?

The focus on intelligent pumps is increasing rapidly in this sector, particularly the pumps with built-in intelligence than the ones with a stand-alone intelligent unit. This will provide a great platform for the Indian pumps and valves industry to gear up with the latest technology in artificial intelligence not only in the products but also in the manufacturing process. Intelligent solutions help monitor processes on a real-time basis to reduce the need for frequent human intervention and promote remote monitoring and control.

Additionally, the next generation of pumps and valves is designed to redefine optimal efficiency levels while increasing energy and water savings significantly. In the long run, these are the future trends which will help improve the longevity and performance of pumps and valves and at the same time help customers scale down their energy and operational expenses.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.