The next generation of MPD most user friendly technology

By EPR Magazine Editorial April 2, 2020 12:26 pm IST

By EPR Magazine Editorial April 2, 2020 12:26 pm IST

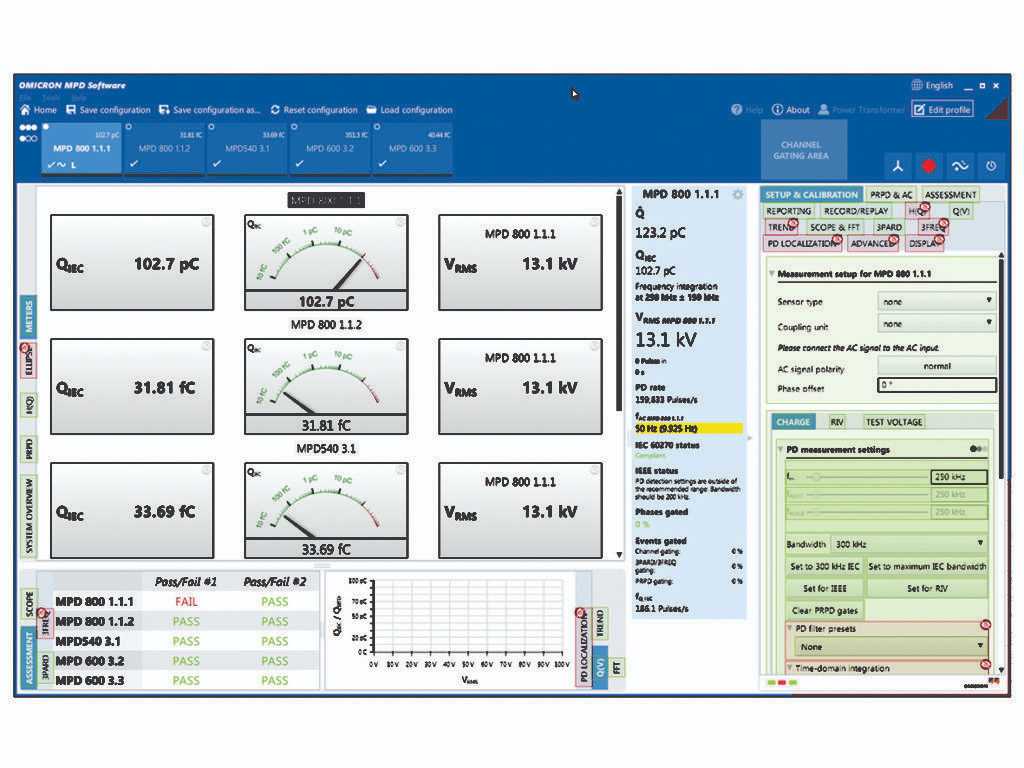

OMICRON’s MPD 800 universal partial discharge (PD) measurement and analysis system represents the next generation of the company’s innovative MPD PD testing technology, which is based on 20 years of MPD customer experience, feedback and their expanding list of requirements for PD testing. Established hardware and software features have been enhanced and new functionality has been added to make the MPD 800 the most complete, accurate, and flexible solution available for PD testing in various applications.

Standard-compliant PD testing

The MPD 800 system performs IEC and IEEE standard-compliant PD measurements and analysis for routine and type testing, factory and site acceptance testing (commissioning), as well as repair testing and troubleshooting in the field.

With very high measurement accuracy, the MPD 800 system enables users to reliably detect, localise and assess the risk of potentially failure-causing PD activity in the insulation of various electrical assets and components. These include power transformers, rotating electrical machines (motors and generators), power cables, switchgear, and industrial drives, as well as bushings, insulators, capacitors and busbars.

High-performance specifications

The MPD 800 system features an expanded adjustable PD frequency range of up to 35 MHz, a faster 125 MS/s sampling rate, an increased PD localisation time greater than 130 μs, and more powerful digital PD filtering capabilities – all of which greatly increase the sensitivity of PD measurements. Additional advanced software-based filtering techniques have been enhanced, such as channel gating, 3PARD (3-Phase Amplitude Relation Diagram) and 3FREQ (3-Center Frequency Relation Diagram), to allow users to reliably distinguish between harmful PD and external noise to ensure highly accurate and reliable PD analysis.

For efficient factory testing on power transformers, the MPD 800 system simultaneously measures and analyses both PD (QIEC) and Radio Influence Voltage (RIV) according to IEEE, NEMA and CISPR standards. Powerful PD localisation techniques accurately pinpoint the location of PD-related defects along entire lengths of power cables.

Convenient battery-powered operation

The rugged and lightweight (1.2 kg / 26.5 lbs.) MPD 800 PD measurement device is powered with the portable re-chargeable battery supplied with the system for up to 16 hours of continuous PD testing. Multiple batteries can be connected via daisy-chain for longer testing periods.

Multi-channel PD measurements

Safe fibre optic connectionsThe use of fibre optic cable connections enables precise synchronicity of all connected MPD 800 measurement devices located in the high-voltage area to a master control device in a safe working area. Fibre optic cables reduce the influence of interference coupling, minimise ground loops, and ensure user safety due to the galvanic isolation they provide.

PD measurement recording

The MPD 800 system software records PD data sets in real time as measurements are being performed to be replayed later for analysis and reporting. The recorded PD data includes all measurement values and relevant system settings, allowing users to apply various analysis and disturbance reduction functions in post analysis without having to repeat the measurement. The recorded PD data sets can also be cut individually and replayed slowly to focus on relevant PD events and analyse them in greater detail.

Flexible, multi-language PD analysis software

The MPD 800 measurement and analysis software is available in multiple languages, including simplified Chinese, English, German, French, Japanese, Portuguese and Russian. Users can easily adjust calibration and measurement settings, as well as how data is displayed.

Individualised reports can be created based on user requirements.

Customisable user profiles

Users can also define individual test specifications, including calibration and measurement settings, based on applicable international standards for specific types of PD tests and test objects, and save them as profiles for current and future use. In addition, users can decide which of the available PD measurement and analysis software features they need for a particular PD measurement, hiding those they do not need at any time for individualised PD testing and reporting. These capabilities make PD testing and analysis much more efficient and easier for users at all skill levels.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.