e-skin flat and the e-skin soft: for cleanrooms

By EPR Magazine Editorial October 16, 2019 6:00 pm IST

By EPR Magazine Editorial October 16, 2019 6:00 pm IST

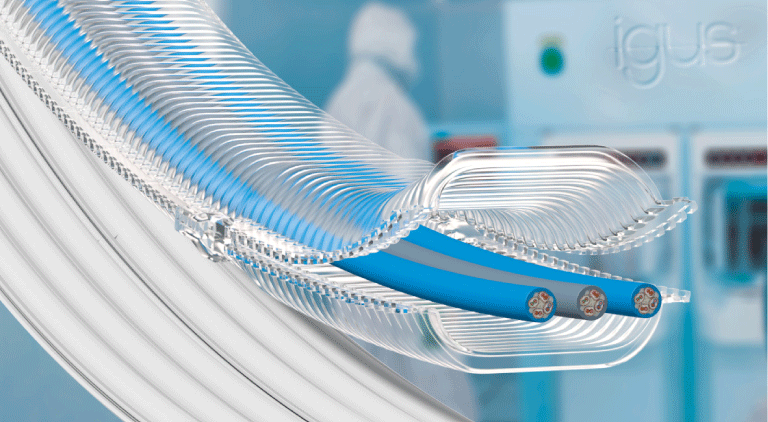

In the production of microchips, OLEDs, LCDs, implants, and semiconductors or in the pharmaceutical industry, there are very high demands in pure manufacturing environment. Because every type of contamination has a direct effect on the product and can lead to serious damage for the manufacturer. Therefore, the conditions on the used machine elements as well as on energy supply systems are particularly high. As a result, igus presented the easily openable e-skin, an enclosed corrugated tube, four years ago. The energy chain for cleanroom applications has now been equipped with a softer material especially for compact installation spaces. The new low-profile energy supply has a chamber design and is easy to fill and maintain.

It has the seal of approval Fraunhofer tested device of the ISO class 1 and in 2018 received the 2nd prize of the Fraunhofer clean technology award “Clean! 2018”. The reasons for this approval were the e-skin is made of tribologically optimised, abrasion-resistant plastic, has a modular structure, and can be filled quickly. To make the e-skin suitable for use in compact rooms, it has now been fitted with a new soft material. The new e-skin soft can also be used in small installation spaces on short unsupported lengths. For very flat installation spaces, igus offers a new solution with a chamber design: the e-skin flat. Both energy chains were convincing in the noise test in the movement. The e-skin soft had a value of 32.4 dBA and the e-skin flat, 29 dBA. This means that the new energy supply systems for cleanrooms are significantly quieter than alternative solutions on the market.

Immediate ready-to-connect system with guaranteed service lifeWe use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.