Ensured preventive maintenance with testo 890 thermal cameras

By EPR Magazine Editorial November 11, 2020 2:59 pm IST

By EPR Magazine Editorial November 11, 2020 2:59 pm IST

Proper maintenance of important assets, components and systems is a necessity for every industry sector and thus it becomes significant that effective methods are implemented for the same. Predictive and preventive maintenance plays a crucial role to ensure the efficient and optimal output of any facility. Testo being the market leader in testing and measuring instruments, provides thermal cameras testo 890 for thermal inspection and troubleshooting of all necessary assets. Be it preventive maintenance of electrical and mechanical machine parts, defects on photovoltaic plants, detecting structural defects, thermal checking of HVAC systems and installations or be it any power plant inspection, testo 890 is the most advanced and recommended measurement tool.

Important areas of application

Considering the general industries like automotive, electrical, cement etc, these thermal cameras are ideal for the early identification of imminent malfunctions or defects on machines by identifying the critical thermal status or hot spots arising due to over-heating of the parts or continuous operation of the components like electric motors, shafts etc. They are also used for detecting defects in switching cabinets, short circuits or over heating in the cables, energy loss from buildings, process control and product quality assurance, identifying wear, insulation damage and defects in kiln and furnaces.

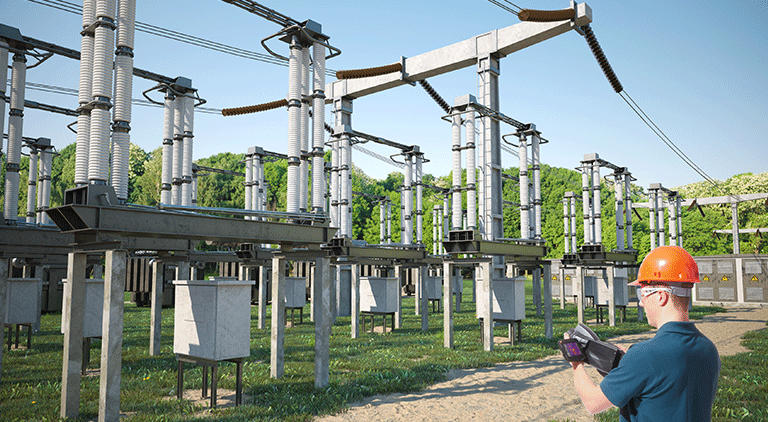

Similarly, power sector plays a very crucial role and one cannot afford to experience a shut down or higher lead time of the power plants. Encountering problems like power losses, system failures and at worse even accidents are uninvited and unforeseen. Thermal Imager testo 890 enhances the life of any power plant at every step. Right from installation phase thermal imagers can be used for setting up benchmark parameters. At generation phase of the power plant preventive and predictive maintenance can help to eliminate unsafe conditions. Most importantly, in power T&D phase, the electrical connection points and insulators for overhead power lines in substations or in high-voltage systems, switch yards and transmission lines can be regularly checked for routine maintenance for thermal anomalies.

Salient Features

• Camera lens of 640 x 480 pixels plus Super Resolution technology (1280 x 960 pixels)

• High temperature measurement up to 1200-degree C

• Fully radiometric video and sequence capturing

Thermal Cameras testo 890 even has built-in fever detection mode and automatic face recognition feature that helps the user to conduct mass scanning of the people. They can be installed at the entrance of the premises over a tripod and a separate LED screen (connected to the instrument via HDMI cable) can be used as a bigger virtual screen to monitor the scan results of the people. It is a must to have tool in times of COVID 19 for any workplace.

For more details, visit

website www.testo.com or write on info@testo.in

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.