Advanced cables powering smart and sustainable energy solutions

By EPR Magazine Editorial November 3, 2023 3:03 pm IST

By EPR Magazine Editorial November 3, 2023 3:03 pm IST

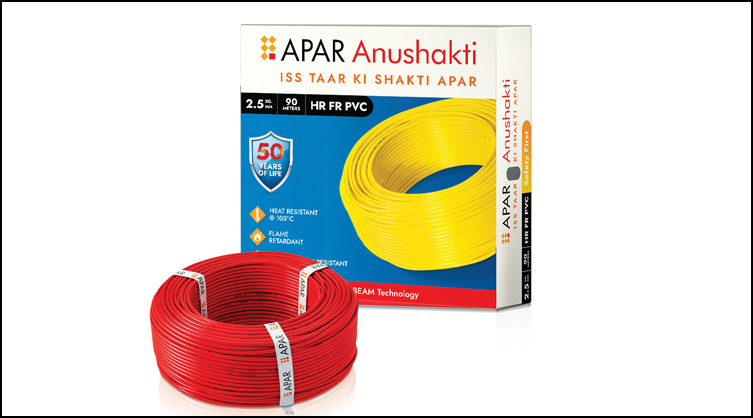

Apar Anushakti wires can withstand temperatures up to 105 degree C, carry 50 percent more current than conventional wires, last for longer than 50 years and save energy also.

India is the 3rd largest electricity producer worldwide, with a target of 500 GW of renewable energy by 2030. The cable market will naturally grow in synchronisation with the power industry. Further, INR 19500 crore for the solar PLI Scheme and 449 ongoing projects are worth $181.86 bn, significantly increasing the demand for sustainable & eco-friendly cables. Apar’s Spokesperson shares insights into the industry.

How are the advanced cables ensuring high-quality power while prioritising environmental sustainability?

Smart cities require a carbon-efficient and energy-efficient energy source comprising various elements like electricity generation, distribution, storage, and transportation. Sustainable cables contain Type C PVC compound with heat-retardant, flame-retardant, low-smoke, low-halogen, and lead-free properties. This heat resistance prevents insulation degradation and minimises conductor heat emission, reducing energy loss in transmission and distribution networks. We offer APAR ANUSHAKTI, a flagship house wire exceeding IS: 694 standards using e-beam technology. It withstands temperatures up to 105°C, carries 50% more current, lasts over 50 years, and conserves energy for the Indian market.

How do green and smart cables contribute to energy efficiency, reduced carbon footprint, and enhanced safety?

In the last decade, the demand for sustainable business practices and consumer concern for long-term environmental impact have risen. Consumer focus on cost-efficiency has shifted, prompting companies to integrate sustainability into production and distribution to stay competitive.

In today’s economy, a company’s ability to adapt to market trends and embrace green initiatives can determine its overall success.

Recently, our cable division introduced specialized OFC cables, tether cables, tactical cables, submarine pressure-tight cables, and torpedo cables for defence and shipyards. APAR ANUSHAKTI, with its fire resistance and 50-year lifespan, has been a key offering.

Our R&D team works on high-ampacity, high-temperature-resistant cables, improving rodent resistance, and developing specialized cables for defence, telecom, renewable energy, and other industrial applications.

How are advanced monitoring and fault detection systems in wires and cables enhancing safety, reliability, and quick response during electrical incidents?

Underground cables suffer various faults due to conditions, wear, and rodents, making fault detection and repair challenging. A system is needed to pinpoint faults precisely for all three phases (R, Y, B) in different conditions.

Leveraging expertise in IoT, big data, and AI enables proactive fault alerts, rule setting, and expert notifications during downtime. This allows power companies to ensure timely responses, enhance SAIDI, SAIFI, and ensure reliable power supply.

Can you highlight the key advancements in wires and cables that are driving the evolution of smart grids and enabling the seamless integration of renewable energy sources?

The energy transmission landscape is shifting towards clean and sustainable solutions, benefiting industrial progress and the nation’s growth. APAR Industries, a prominent Indian cable manufacturer, supports this transition.

In Renewable Energy: APAR Industries has international certifications like BS EN 50618, TUV 2007 & 2012, IEC 62930:2017, and UL 4703 for cables with exceptional attributes. These cables offer high dielectric strength, flame resistance, resistance to oil, chemicals, and resilience to abrasion and cracking. They are highly flexible, operate efficiently at temperatures up to 120°C, and have a lifespan of over 25 years. Rated for 1.8 kV DC operation and halogen-free, they offer a 15% higher current rating than traditional cables. Options include flexible aluminium conductors and various armour types. APAR Industries also provides solar PV cables with rodent resistance and AS/NZ-compliant nylon-jacketed cables. They’ve commissioned a new CCV line for elastomeric cables up to 75KV, enhancing their international cable supply for mining.

In Wind Power: APAR Industries offers comprehensive harness solutions from nacelle to turbine, including LV power cables, control cables, sensor harnesses, OFC patch cords, and sub-station/transmission cables.

In the EV Segment: APAR Industries is the first Indian cable manufacturer to enter the EV segment, automating production to meet global standards. They plan to produce harnesses for 0.3 lakh passenger vehicles and 1 lakh three-wheelers in the next two years.

Credentials of Apar EV Wiring and Solutions: Their IATF-certified manufacturing unit in Khatalwada, Gujarat, houses four E-beam accelerators and manages cot tube production. All EV wiring cables are electron beam cured, type D, meeting international standards with a wide temperature range of -40°C to +150°C. Their EV charger cables are TUV and UK Cert certified for EN 50620 and EN 62893-4-1. APAR Industries has successfully launched EV chargers up to AC 63 Amp-415V/DC 1000V Load 200 Amp. They’ve designed and supplied numerous HV cable harnesses for over 1200 EVs.Manufacturing Range for the EV Segment: APAR Industries offers a comprehensive product range, including screened battery cables from 0.5 sq. to 300 sq. mm, featuring multi-strand copper conductors insulated with e-beam crosslinked polymers, screened with copper/aluminium/steel, and sheathed with XLPO polymers for a temperature range of -40°C to +150°C. Specialized cables are available for higher temperature needs. They also provide nylon cot tubes in various sizes, complete HV cable harness solutions, and various EV charger composite cables and assemblies, including CCS2 type chargers suitable for AC and DC charging.

How are advanced wires and cables optimising energy transmission, reducing losses, and enhancing grid stability?

Technical losses in power systems occur due to energy dissipated in the conductors and equipment used for transmission, transformation, sub-transmission and power distribution. Summarising losses due to cables can be mainly due to 4 reasons.

Size of the cable: The size of the conductor/cable is an important parameter as it determines the current density and the resistance of the line. A lower conductor size can cause high I2R losses (a technical loss that can be reduced) and a high voltage drop, which causes a loss of revenue.

Tapping of underground service cables: The service cables must be visible so that tapping of cables can be detected. Underground service cables should be avoided as they are not visible for routine inspection.

Connections: Loose connections of the service cables can result in sparking and are another source of avoidable energy loss.

Bimetallic connections: Generally, the LT conductor is of aluminium, while at many places, the service cable is of copper. Connecting aluminium and copper creates a bi-metallic junction, leading to corrosion, high resistance and failure.

APAR Industries, as always with its innovative solution, comes to arrest the electrocution accidents problem. Medium voltage covered conductors (MVCC) are the best economical solutions wherever the safety of humans and wildlife is challenged or compromised by bare conductors.

Our MVCC is loaded with the below features.

· 100 percent safe from power line tripping:

· The insulation on conductors increases the life of overhead conductor

· Operating temperature up to 105°C allows handling high loads

· Suitable for monsoons, humidity, high wind zones, and high dust or sandstorm areas

– Fire retardant outer sheath to avoid forest fire hazard.

Spokesperson- Shashi Amin, CEO- Cable Solutions, Company, Apar Industries Limited.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.