Automation and control solutions propelling next-generation energy infrastructures

By EPR Magazine Editorial January 3, 2024 4:50 pm IST

By EPR Magazine Editorial January 3, 2024 4:50 pm IST

The software and configuration tools like Crimson® and N-View™ make integrating intelligent new equipment monitoring capabilities with existing SCADA, maintenance management and other systems easy.

Red Lion’s Access, Connect and Visualize series of products are instrumental in transforming India’s energy sector towards sustainability. Through innovative products, such as FlexEdge® Intelligent Edge Automation Platform, Secure Remote Access routers, NT5000 Ethernet switches and CR3000/ Graphite HMIs, Red Lion enhances reliability, real-time data access, and cybersecurity, making it a trusted partner in advancing industrial automation within the energy industry. Jayprakash Patil exclusively shares the company’s know-how with the EPR Magazine.

Transformation towards sustainability

Red Lion allows power sector companies to access, connect, and visualise data from different types of assets remotely. These include wind turbines, solar panels and submersible hydroelectric generators. As key production variables change by seconds, operators need real-time data collection, communication and control systems.

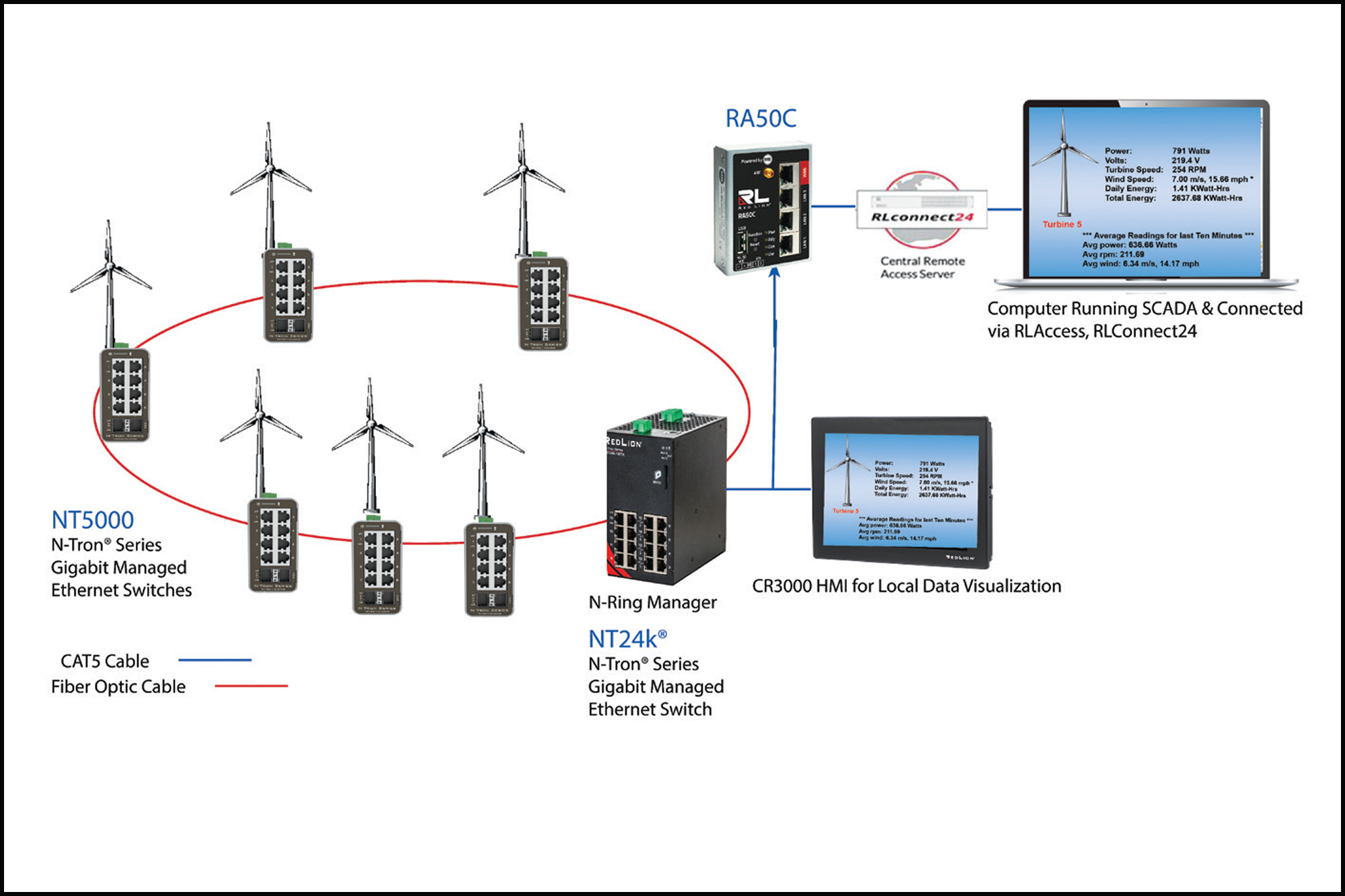

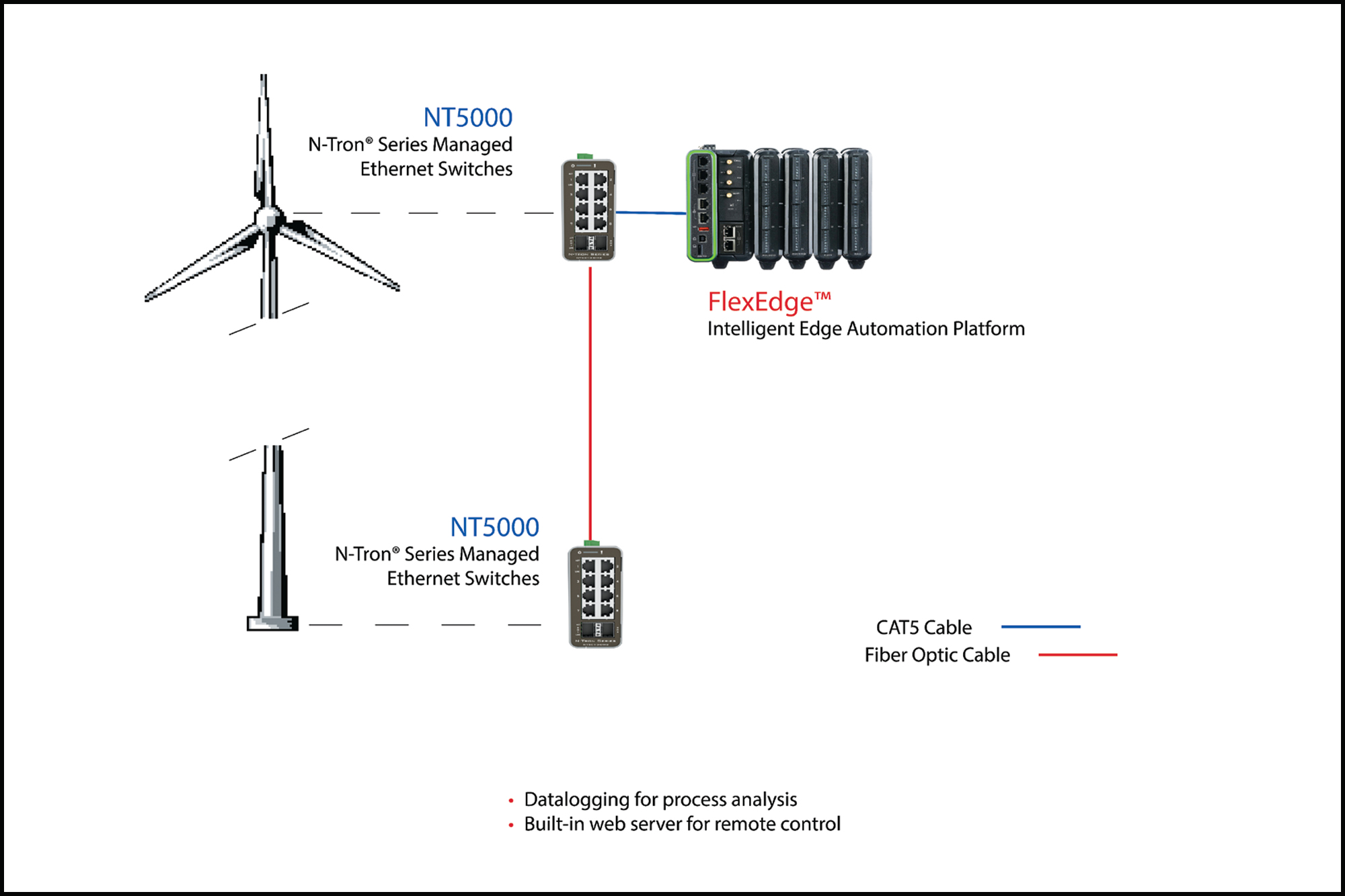

Red Lion’s Connect solutions include the NT5000 and NT24k managed Ethernet switches, that pass data transmission and quickly communicate and process information in operational technology networks. In addition, the Secured Remote Access Platform and FlexEdge® Intelligent Edge Automation Platform provide remote access and data monitoring, HMI series like CR3000 & the rugged Graphite series enable companies to visualise and monitor the collected data.

Improving reliability in India’s energy sector

Companies worldwide rely on Red Lion to keep systems running safely and reliably around the clock, regardless of location. Production must become more dependable and cost-effective to scale the wind, solar, and hydro sources reliably. Energy sources of the future will require next-generation infrastructures.

Reliable data access and communications using our Secure Remote Access routers and FlexEdge devices provide the operator with the required information. This information is necessary to instantly adjust blades, turbines and valves to maximise power generation and monitor equipment durability. Timely access to remote data is essential to predicting required maintenance and minimising costly downtime. The software and configuration tools by Red Lion, like Crimson® and N-View™, make it easy to integrate intelligent new equipment monitoring capabilities with existing SCADA, maintenance management and other systems.

NT5000 and NT24K Ethernet switches by Red Lion are designed to provide rugged reliability and high performance. Designed for fault tolerance, the switches use dual‐independent power supplies and are fully compatible with multimode and single‐mode fibre optic ring network topologies. Built‐in redundancy ensures data automatically gets rerouted. Ring technology also enables maintenance to be performed without communication loss. Switch performance under electrical transient fault conditions makes it one of the most reliable features for Energy applications.Built for reliability and ease of use, Red Lion’s rugged industrial products deliver the performance required to help ensure infrastructures stay up and running. Red Lion is considered a trusted partner for industrial automation and networking solutions within the energy industry. As a trusted partner, Red Lion helps organisations worldwide develop systems that improve output efficiency and reduce downtime.

Cybersecurity concerns

Cyber security is a crucial issue in all industrial sectors, including Energy. Unfortunately, the cases of cyberattacks that paralyse entire productions or even ruin companies are increasing. Global lloT-enabled networking and automation also harbour risks, and one becomes vulnerable.

Red Lion products offer security features that help protect against attacks. For example, NT5000 Gigabit Managed Ethernet Switches with multi-level security features that were introduced to the market to help keep networks connected and protected.

At the level of network connectivity, the IEC62443 standard establishes requirements for dividing systems into segments as a key security measure to fortify industrial systems. A safer approach is to segment the factory floor/ wind turbine systems into multiple smaller containers called zones. Zones create a layered security boundary and help maintain the same security level for all devices within that zone. Zones are not isolated from one another. However, communication between devices in different zones can be enabled through conduits that control and monitor traffic in and out of individual segments.

A better and easier method is possible with Red Lion’s RA10C compact industrial firewall by simply installing the RA10C in the panel as the conduit between two zones (e.g. Line A and Line B) and providing the necessary segmentation between zones. The unit provides firewall protection, traffic control and monitoring and eliminates the need for VLANs and routers.

Jayprakash Patil, Technical Manager- Red Lion SAARC & ME

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.