High-performance conductors contribute to a resilient transmission network

By EPR Magazine Editorial July 24, 2023 1:54 pm IST

By EPR Magazine Editorial July 24, 2023 1:54 pm IST

High-performance conductors are critical to sustaining effective power transmission, explains Hitesh Mundhada, Vice President for South Asia at CTC Global. He describes how High-Performance Conductors (HPCs), such as CTC Global’s ACCC® Conductor, transform the industry, improve dependability, and support a sustainable grid.

India is rapidly progressing towards an energy transition’ by investing heavily in the renewable sector. What is your perspective on this? What do you think is working, and what will be the challenges?

India has made notable progress towards the energy transition in recent years, positioning itself as a significant player in the global effort. Over the past decade, India has seen a more than 25-fold increase in solar power installed capacity. It has set a target to achieve 50 percent capacity from non-fossil fuel sources by 2030. Due to economic development, urbanisation, and electrification, India’s power demand will likely double by the end of 2030. However, despite the progress, challenges lie ahead. One key challenge is the integration of the newly produced renewable energy sources into the existing power grid. I believe India can move much closer to its Net Zero goal by transitioning towards cleaner energy sources and developing a robust transmission infrastructure. With the rapid growth in renewable energy capacity, investing in infrastructure that can efficiently transfer green power to areas of demand is essential. Essentially, ‘No Transition without Transmission’!

How are your High-Performance Conductors (HPCs) reshaping the industry and revolutionising power transmission? How are they enhancing reliability and resilience in power T&D infrastructure, building a safer and more sustainable grid?

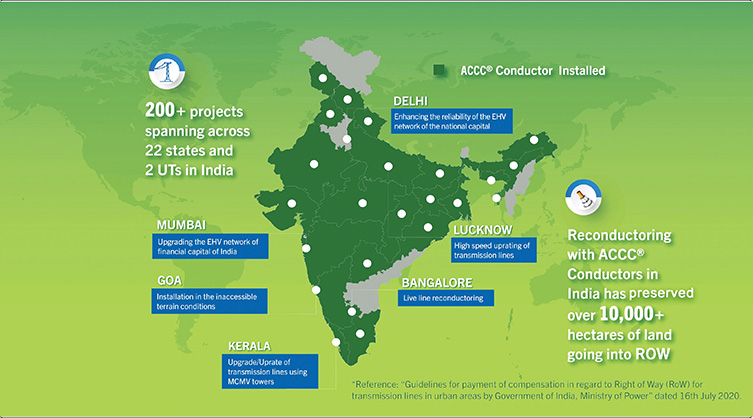

HPCs like CTC Global’s ACCC® Conductor revolutionise the transmission industry by increasing capacity, minimising sag, reducing line losses, and promoting a greener and more sustainable power system. In India and globally, HPCs enable the cost-effective retrofitting of existing transmission infrastructure, eliminating right-of-way acquisition challenges while reducing emissions and environmental impact. For instance, Delhi Transco Ltd., upgraded the 220 kV Gopalpur-Mandola line in Delhi using an ACCC Drake-size conductor to replace the existing ACSR Zebra-size conductor. This increased line capacity by almost double and improved the efficiency and reliability of Delhi Transco’s grid. And as of today, 35 percent of DTL’s 220KV Network operates on ACCC® Conductors. In India, the re-conductoring of existing lines with ACCC® Conductors has preserved 10,000+ hectares of land.

As we understand, CTC Global has developed a confirmation system that can check the integrity of the installed conductors. Please enlighten us more on that.Even with meticulous planning and project implementation, experienced utilities understand that issues can arise during conductor installation. The ACCC InfoCore® System, developed by CTC Global, guarantees the integrity of conductors from the factory to the field. The system incorporates special fibres embedded in the core of the ACCC® Conductor, which can confirm the conductor’s integrity after stringing in just a few minutes. Utility companies worldwide are addressing grid reliability concerns, and the ACCC InfoCore® System provides ‘peace of mind’ to utility engineers by ensuring the reliability and performance of the conductor.

CTC Global has recently announced its India facility. Tell us more about your experience and plans for the Indian market.

CTC Global has been serving the Indian power sector for over a decade now. Along with our manufacturing partners in India, CTC has completed over 200 projects spanning 22 states and 2 UTs, which are helping utilities lower line losses, add substantial capacity, and remove bottlenecks that often prevent utilities from accessing the cheapest and greenest source of generation and can increase costs to the utilities and consumers. The CTC is committed to supporting India’s ambitious energy transition goals. CTC is constructing a state-of-the-art production and test facility in Pune, India, to contribute further. This facility will utilise cutting-edge materials and production techniques to manufacture CTC’s renowned ACCC® Core and ACCC® InfoCore products. By producing carbon core composite core within India for high-performance conductor production, CTC Global aims to enhance support levels for our manufacturing partners and meet the challenges and opportunities of Make-in-India.

For more details, visit: https://ctcglobal.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.