Innovative materials improve solar panel durability in Indian conditions

By EPR Magazine Editorial July 24, 2023 12:52 pm IST

By EPR Magazine Editorial July 24, 2023 12:52 pm IST

Discussing the need for solar panel cleaning, Nitin Barvaliya, General Manager at Pahal Solar, emphasises research on anti-reflective coatings, robust encapsulants, and new cell technologies for more durable, efficient, and high-performing solar panels.

Which innovative cleaning techniques and materials are being explored for solar panel maintenance in India?

Various advancements are being explored to optimise energy generation and reduce water consumption in this field.

One promising approach is using self-cleaning coatings designed to repel dust, dirt, and other particles accumulating on solar panels. These coatings reduce the need for frequent manual cleaning, helping maintain optimal performance and maximise energy output.

Another development is the utilisation of automated cleaning robots equipped with advanced sensors and algorithms. These robots navigate and clean solar panels efficiently, saving time and minimising labour while ensuring thorough cleaning.

Additionally, water-efficient cleaning methods are being researched to address water scarcity concerns. Researchers are developing innovative solutions that use minimal water while effectively removing dirt from solar panels.

By incorporating these techniques into solar panel maintenance, India aims to optimise energy generation while minimising environmental impact. These advancements enhance panel efficiency and longevity and contribute to sustainable resource management.

How can proactive maintenance strategies be developed to minimise downtime and maximise energy generation from solar projects?

Developing proactive maintenance strategies for solar projects minimises downtime and maximises energy generation. Here are steps to help you develop effective strategies:

Regular Inspections: Conduct routine inspections to identify potential issues and maintenance requirements, including solar panels, wiring, inverters, and other components.

Implement Predictive Maintenance: Utilise techniques like thermal imaging and performance monitoring to detect early signs of equipment failure or inefficiencies, enabling timely repairs or replacements.

Establish a Preventive Maintenance Schedule: Create a comprehensive schedule for tasks such as panel cleaning, connection tightening, and electrical system inspection to prevent issues and ensure optimal performance.

Remote Monitoring: Install advanced systems for real-time data on project performance, allowing you to promptly address deviations from expected energy generation.

Training and Documentation: Train staff on maintenance procedures and maintain thorough documentation for efficient troubleshooting and knowledge sharing.Engage with Manufacturers and Suppliers: Stay in touch with equipment manufacturers or suppliers for best practices, recommended maintenance procedures, and product-specific considerations.

Continuous Improvement: Regularly review the effectiveness of your maintenance strategy by analysing historical data on downtime incidents, energy generation patterns, and repair costs. Refine your strategy based on the insights you gain.

By implementing these proactive maintenance strategies, you can minimise downtime, optimise energy generation, extend equipment lifespan, reduce operating costs, and maximise return on investment.

How are thermal imaging and drones used for infrared inspections of solar panels in India, enabling early detection of issues?

Research and implementation efforts are focused on anti-reflective coatings to improve the durability and longevity of solar panels. Coatings such as silicon nitride, silicon carbide, titania, and double-sided textured surfaces are being studied to reduce light reflection and enhance light absorption.

Researchers are exploring new encapsulant materials to pursue durable solar panels. Materials like fluorine-doped tin oxide nanocoatings, carbon nanotube films, and titanium dioxide are under investigation for their ability to withstand harsh environmental conditions.

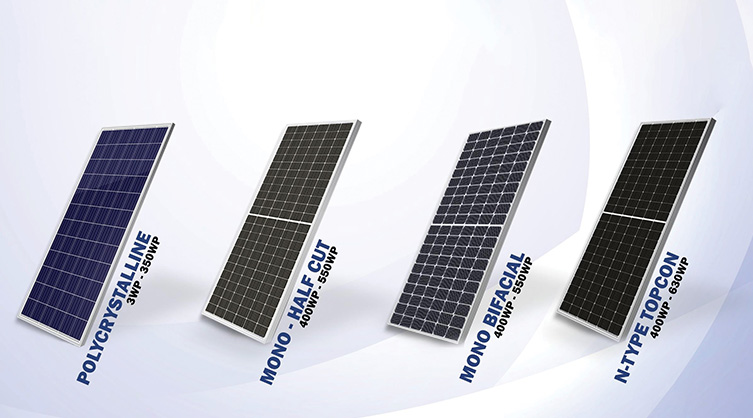

To enhance the performance and efficiency of solar panels in India, improved cell technologies are being researched and implemented. Two notable configurations, the Passivated Emitter and Rear Cell (PERC) and the Functional Rear-Side Contact Cell (FRC), are being explored. These technologies incorporate dielectric passivation layers to minimise recombination losses and increase the surface area for better light absorption.

What advancements in solar panel materials are happening to enhance durability and longevity in India’s challenging environmental conditions?

Research and implementation efforts are focused on anti-reflective coatings to improve the durability and longevity of solar panels. Coatings like silicon nitride, silicon carbide, titania, and double-sided textured surfaces are being studied to reduce light reflection and enhance light absorption.

Researchers are exploring new encapsulant materials in the quest for durable solar panels. Materials such as fluorine-doped tin oxide nanocoatings, carbon nanotube films, and titanium dioxide are being investigated for their ability to withstand harsh environmental conditions.

To enhance the performance and efficiency of solar panels in India, improved cell technologies are being researched and implemented. Two notable configurations, passivated emitter and rear cell (PERC) and functional rear-side contact cell (FRC), are being explored. These technologies incorporate dielectric passivation layers to minimise recombination losses and increase the surface area for better light absorption.

For more details, visit: https://pahalsolar.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.