Rayzon Solar moved to the 10BB half-cut mono PERC modules for better efficiency

By EPR Magazine Editorial August 25, 2023 11:59 am IST

By EPR Magazine Editorial August 25, 2023 11:59 am IST

Hardik Kothiya, Director, Rayzon Solar, discusses innovations to boost efficiency, cost-effectiveness, and environmental sustainability for solar PV in conversation with EPR Magazine.

Which key factors are driving the growth of the solar PV market in India?

Rayzon Solar thrives in India’s solar PV market due to the government’s renewable energy vision, seen through policies like the National Solar Mission and the Solar Park Scheme, which offer incentives and tax benefits. These policies attract investments, vitalising the solar sector, aligned with India’s goals of 100 GW by 2022 and 450 GW by 2030. Solar technology’s cost reduction drives its competitiveness, diminishing reliance on imported fossil fuels for enhanced energy security. This echoes eco-friendly concerns, aligning with India’s climate change and pollution mitigation efforts.

Solar power aligns with broader goals of job creation, rural electrification, and universal electricity access. It fosters employment and reaches remote areas. Private sector involvement, technological growth, and international agreements further accelerate momentum. As solar technology matures, it harmonises with India’s aims for economic progress, social advancement, and environmental welfare.

How dependent is our economy on imported raw materials like silicon wafers and other components?

Rayzon Solar is determined to strengthen its local solar manufacturing, aiming to reduce reliance on external sources and establish a self-sufficient supply chain. Government incentives have spurred growth in solar cell and module production to meet increasing installation demands. Yet, despite progress, the solar panel industry still depends on imported silicon cells, mainly from countries like China, Taiwan, Vietnam, and Cambodia. While policies support local manufacturing, critical components like silicon cells remain globally sourced.

This reliance on imports exposes the sector to supply chain disruptions and market volatility, potentially impacting the competitiveness of domestically produced solar equipment. Rayzon Solar supports the Indian government’s efforts to boost local manufacturing and reduce imports, aiming to enhance industry resilience and self-reliance. These ongoing endeavours are expected to bolster exports and solidify the industry’s self-sustaining position.

How have government policies and incentives impacted India’s solar PV and solar cell manufacturing industry?

Rayzon Solar acknowledges the profound influence of government policies and incentives on India’s solar PV and solar cell manufacturing sectors. The National Solar Mission, aiming to achieve 100 GW of solar capacity by 2022 and later scale to 450 GW by 2030, has been a catalyst for growth and investment. Financial incentives such as generation-based perks, capital subsidies, and tax advantages have attracted investors, driving down manufacturing costs. Research and development backing has nurtured innovation for efficient solar technologies.

In parallel, domestic manufacturing has flourished through initiatives like the Production-Linked Incentive (PLI) scheme. These endeavours intend to bolster local production and diminish import reliance. Streamlined regulations have enhanced business ease, expediting project approvals. Grid integration policies and infrastructure upgrades have mitigated challenges tied to solar power intermittency.

Net metering and feed-in tariffs have spurred solar adoption by enabling grid energy feed-in and ensuring producer revenue. International collaborations have facilitated technology transfer and knowledge dissemination. Skill development initiatives have cultivated a proficient workforce for installation and maintenance. While India emerges as a global solar leader, ongoing stability and intermittency concerns remain focal, demanding continued attention for sustained industry growth.Are there any regulatory challenges or bottlenecks that manufacturers face, such as permitting issues or trade barriers for raw materials?

Solar manufacturers like Rayzon Solar often confront regulatory hurdles that hinder smooth operations. Obtaining permits is challenging due to stringent environmental and safety requirements, raising costs and project timelines. Trade complications like tariffs and shifting agreements disrupt supply chains, inflating expenses, especially for those reliant on imports. Protecting intellectual property is crucial, as innovative products are vulnerable to imitation.

Maintaining quality and industry standards demands extra spending and rigorous testing. Diverse labour laws complicate recruitment, compensation, and benefits—geopolitical dynamics and unforeseen events like the recent pandemic impact supply chains, requiring adaptability.

To navigate these challenges, manufacturers need regulatory expertise. Proactively engaging with authorities and using risk management strategies are vital. Partnering with industry peers and stakeholders enhances regulatory compliance. Keeping up with evolving regulations demands constant vigilance, but the rewards for these efforts are substantial.

Which innovations have you recently added to your products to enhance the technology capabilities?

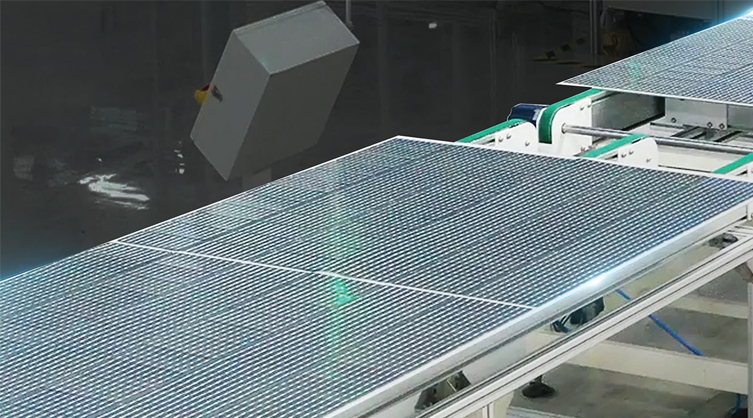

In line with the latest trends in the PV industry, Rayzon Solar has moved from the 5BB full-cell module design to the 10BB half-cut mono PERC modules, which have improved our module efficiency and reduced the chances of hot spots in the solar cells during field operation, thereby enhancing the product’s reliability. These large-format modules with a rated power output higher than 500 Wp have a large span, so the modules tend to bow in the middle. To increase the strength of the module and reduce the bowing, we have improved the grade of the aluminium frame from 6063 Temper T5 to 6005 Temper T6. Further, we have modified our frame design by removing the mounting holes close to the module’s centre at the Y-pitch of 400 mm (used for mounting in tracker-based systems only), as these holes act as weak points in the frame. Also, Rayzon Solar has introduced stringent quality checks for the incoming raw materials, like the pressure cooker test, volume resistivity test, potential induced degradation (PID) test, UV test, etc., to ensure the reliability of our products. We are further adopting the N-type TOPCon technology to improve the efficiency and reliability of our modules.

How are Indian manufacturers adopting innovations to improve efficiency, cost-effectiveness, and environmental sustainability?

Indian manufacturers like Rayzon Solar and others actively leverage innovation to boost efficiency, cost-effectiveness, and environmental sustainability. This includes integrating advanced technologies like automation and AI for streamlined production. IoT devices and data analytics are harnessed for real-time monitoring and process optimisation. Lean manufacturing principles are applied to minimise waste and excess inventory, enhancing cost efficiency. A shift towards renewable energy sources such as solar and wind power reduces carbon footprints and energy expenses.

Circular economy practices involving recycling and remanufacturing are gaining traction to curtail waste. Manufacturers also focus on sustainable sourcing and adopting eco-friendly materials to align with green supply chain initiatives. Additive manufacturing and 3D printing enable efficient prototyping and customisation while reducing material waste. Collaborative research and development efforts with institutions and start-ups are fostering innovative solutions. By complying with rigorous environmental regulations and obtaining green certifications, manufacturers showcase their commitment to sustainability, attracting environmentally conscious consumers. This holistic approach to innovation drives business growth and contributes to India’s broader sustainability objectives.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.