RAYZON’S TOPCon technology is revolutionising solar cell manufacturing

By EPR Magazine Editorial July 24, 2023 1:06 pm IST

By EPR Magazine Editorial July 24, 2023 1:06 pm IST

Through relentless advancements in solar technology and high-efficiency solar cells, coupled with cutting-edge module designs, we are set to witness an exceptional transformation in performance, says Hardik Kothiya, Director of Rayzon Solar.

How does TOPCon technology contribute to traditional solar cell technologies in terms of efficiency and power output? How has it contributed to the advancement of solar PV manufacturing?

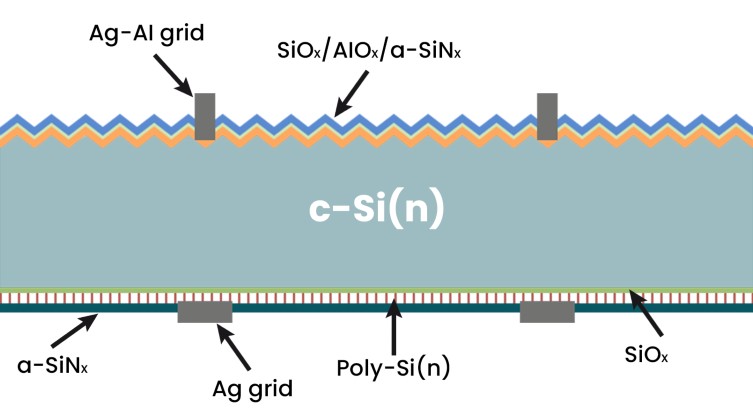

TOPCon technology has revolutionised traditional solar cell technologies by improving efficiency, power output, and manufacturing processes. It achieves better passivation through a thin tunnel oxide layer, which minimises carrier recombination and maximises the collection of photo-generated carriers, leading to higher conversion efficiency. TOPCon cells demonstrate increased power output with higher open-circuit voltages and fill factors. Additionally, they exhibit lower temperature coefficients, ensuring stable performance even under varying temperatures.

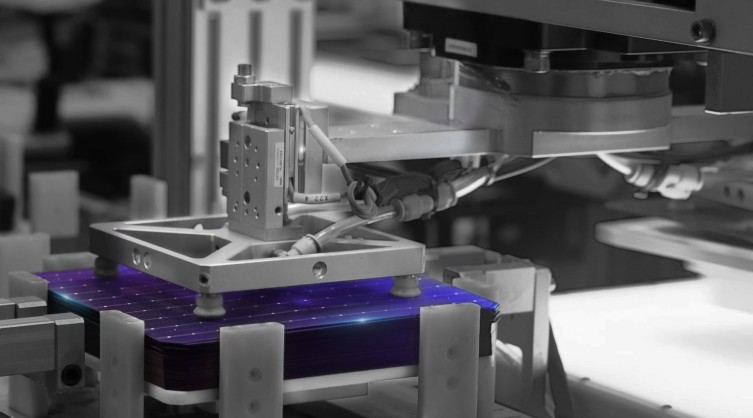

This technology has driven advancements in solar PV manufacturing. New fabrication techniques, such as atomic layer deposition (ALD), have been developed for the precise deposition of the thin tunnel oxide layer. The seamless integration of TOPCon cells into existing manufacturing processes has facilitated easier adoption and commercialisation.

According to Rayzon’s R&D team, TOPCon technology has significantly enhanced traditional solar cell technologies by improving efficiency, increasing power output, and advancing manufacturing processes. These developments have accelerated the adoption of more efficient solar cell designs, paving the way for a sustainable and renewable energy future.

What are the advantages and features of TOPCon technology and how do they address the limitations of previous solar cell technologies?

TOPCon technology addresses the limitations of previous solar cell technologies through its key features and advantages. It provides enhanced passivation with a thin tunnel oxide layer, which reduces carrier recombination and improves efficiency. This results in higher conversion efficiencies, increased power output, and improved stability under varying temperatures. The seamless integration of TOPCon cells into existing manufacturing processes allows for easier adoption and scalability. Despite potential additional fabrication steps, the technology’s improved efficiency and power output can offset the costs, making it a cost-effective option for solar PV systems. TOPCon technology represents a significant advancement in solar cell technology, overcoming limitations and paving the way for more efficient and commercially viable solar energy solutions.

What are the major challenges and obstacles faced during the integration and implementation of TOPCon technology in solar PV manufacturing processes?

From the perspective of solar cell manufacturing, there are challenges related to the uniform diffusion of Boron in the N-type wafer, which requires a high processing temperature of nearly 1000 °C. Additionally, the deposition of the polysilicon layer using LPCVD presents its challenges, as some manufacturers have reported issues with silicon dust depositing on the reactor surfaces, necessitating frequent cleaning and causing associated downtime.

When converting a Rayzon Mono PERC module production line to a Rayzon TOPCon module production line, the main change occurs in the Tabber-Stringer. This is because TOPCon solar cells have 16 busbars, whereas regular Mono PERC solar cells have 10 busbars. Another challenge arises from the thinness of TOPCon solar cells, which measure approximately 140 microns. This poses difficulties in soldering the ribbons, as the solar cells can develop micro-cracks if the soldering time or temperature exceeds the limits.How does the cost-effectiveness of TOPCon technology compare to other solar PV manufacturing methods? What strategies or innovations does Rayzon Solar employ to optimise production costs?

In module manufacturing, the production cost is influenced by the raw material cost (cost of solar cells and other raw materials) and the processing cost (cost of machinery, manpower, and rejections). When compared with Rayzon Mono PERC module production, the cost of Rayzon TOPCon production is higher, primarily due to the higher price of the solar cells and the higher rejections due to cell breakage (as the cell thickness is very low). However, the cell breakage rate is strictly controlled at the Tabber-stringer by the Rayzon production team based on feedback from the Quality Control team, which keeps a close eye on the micro-cracks generated in the Tabber-stringer using the integrated EL tester.

With the growing demand for renewable energy sources, what market trends do you foresee for the solar PV industry in the next five years?

Over the next five years, Rayzon’s observation is that the solar PV industry is expected to witness several key market trends. Continued cost reduction will drive the adoption of solar energy as prices decrease due to technological advancements and economies of scale. Utility-scale solar installations will expand as governments and utilities invest in large-scale projects to meet renewable energy targets. Distributed generation will experience accelerated growth, fueled by decreasing costs, supportive policies, and the desire for energy independence. The integration of energy storage will become increasingly important, allowing for better utilisation of solar power and grid stability. Advancements in solar technology, including higher-efficiency cells and improved module design, will continue to enhance performance. Digitalisation and data analytics will play a crucial role in optimising solar PV systems by enabling real-time monitoring, performance optimisation, and proactive maintenance. Furthermore, emerging markets, particularly in Asia, Africa, and Latin America, will play a significant role in the industry’s growth, driven by their vast solar resources and increasing energy demand. Overall, these trends point towards a positive outlook for the solar PV industry in the coming years.

How is Rayzon Solar positioning itself to capitalise on these trends and stay ahead of the competition?

Rayzon Solar is strategically positioning itself as a front runner in the solar panel market, aiming to capitalise on emerging trends and surpass competitors. We prioritise substantial investments in research and development to drive technological advancements, enhancing the efficiency, durability, and affordability of our solar panels. By streamlining processes and optimising supply chains, we relentlessly work to reduce production costs, enabling us to offer competitive pricing to our customers. Diversifying our product portfolio is a key focus area as we develop panels tailored for utility-scale projects.

Through strategic acquisitions and partnerships, Rayzon ensures vertical integration, allowing us to have control over critical components and secure a dependable supply chain. Expanding our reach into international markets enables us to tap into the growing global solar sector. Sustainability is at the core of our operations, as we incorporate eco-friendly practices, implement recycling programs, and prioritise renewable energy use in our facilities.

For more details, visit: https://www.rayzonsolar.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.