Thermal imaging cameras unlock vast potential through versatile applications

By Staff Report October 16, 2024 7:24 pm IST

By Staff Report October 16, 2024 7:24 pm IST

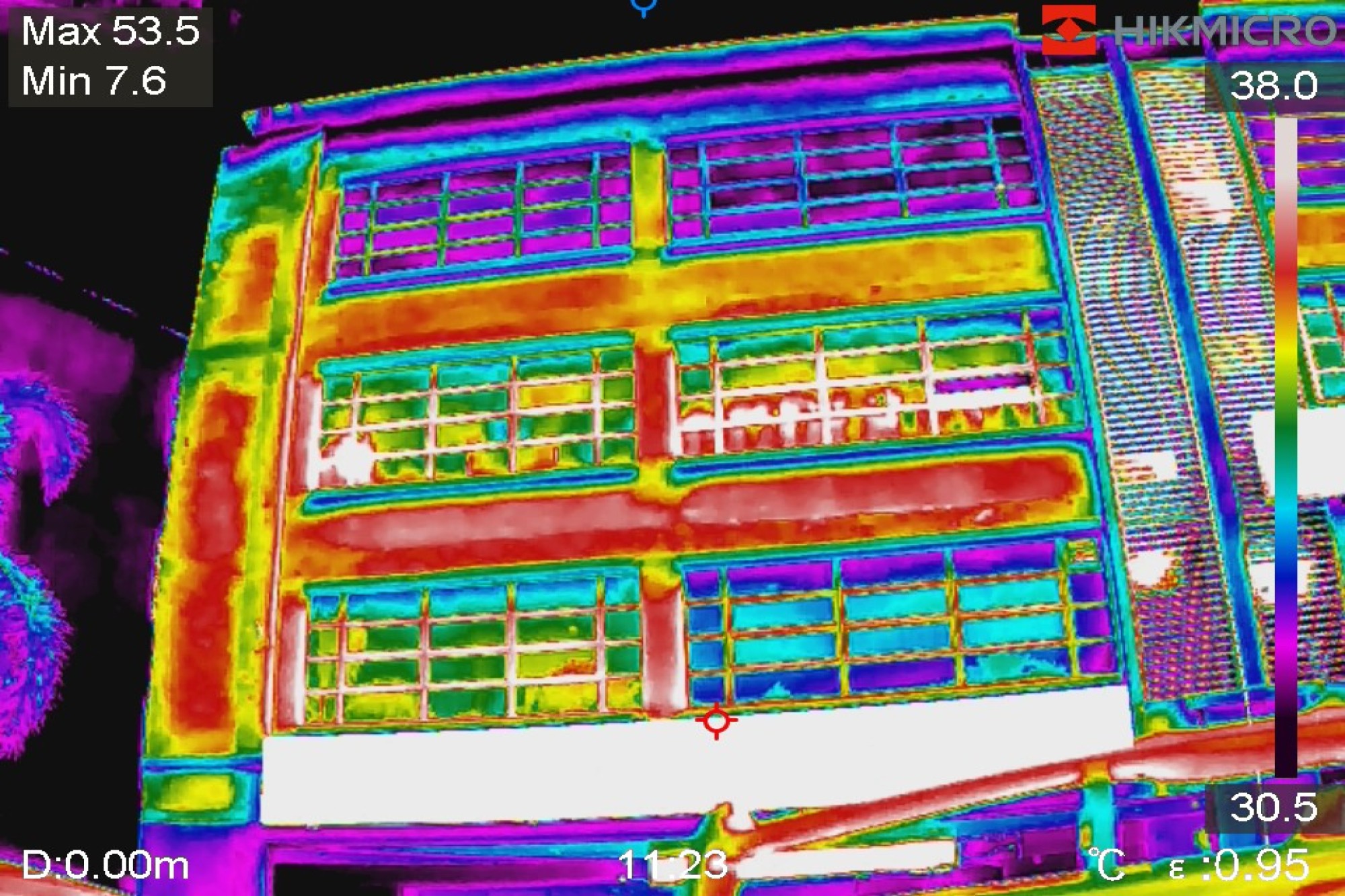

These cameras effortlessly go above and beyond the competition by helping owners of residential structures apply corrective action and save money by detecting heat loss and air infiltration. Also, in electrical faults it helps in identifying hot spots before equipment failures cause expensive repairs or become a safety problem or fire hazard.

Thermal imaging is not just a way to capture images on the infrared spectrum, allowing you to see what you can’t capture with the naked eye. The myriad of possibilities that come with those images make thermal imaging cameras worthwhile. It is an illuminating solution that can help you outperform your competition. It can save money, prevent catastrophes, and even save lives. Discover just a few of the applications for thermal cameras to diagnose otherwise invisible problems while revealing the best possible solutions.

Applications where thermal imaging is useful

Thermal imaging is used in surprising ways across a wide range of industries. Many contractors, technicians, and engineers can benefit from portable thermal imaging devices. Check out the following applications, which will help individual professionals and entire industries transform how they prevent, seek, and solve some of their most common challenges.

Insulation: Identify areas with missing or inadequate insulation.

Energy audits: Effortlessly go above and beyond the competition by helping owners of residential structures apply corrective action and save money by detecting heat loss and air infiltration.

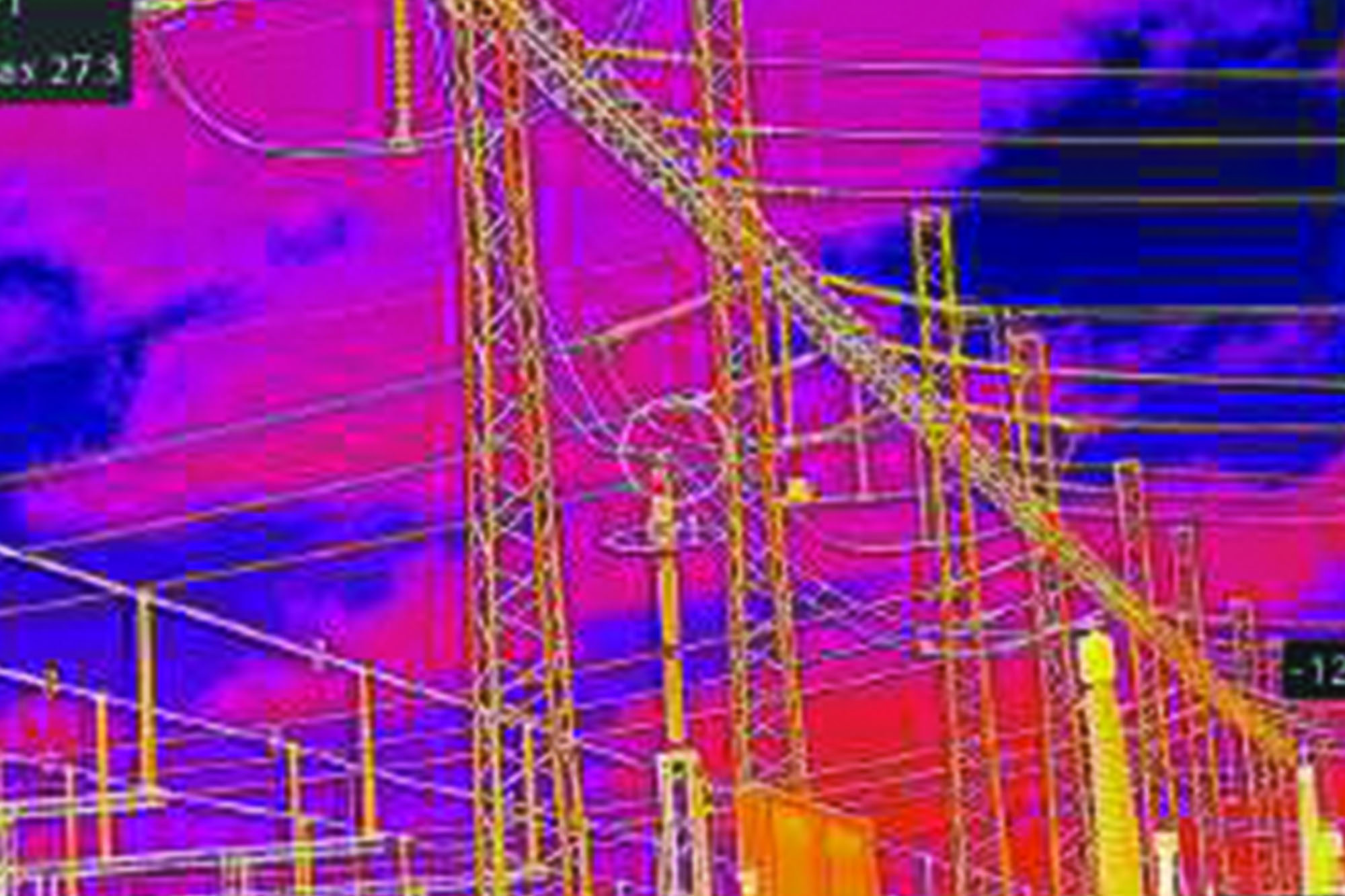

Electrical faults: Identify hot spots before equipment failures cause expensive repairs or become a safety problem or fire hazard.

Condition-based maintenance vs time-based maintenance

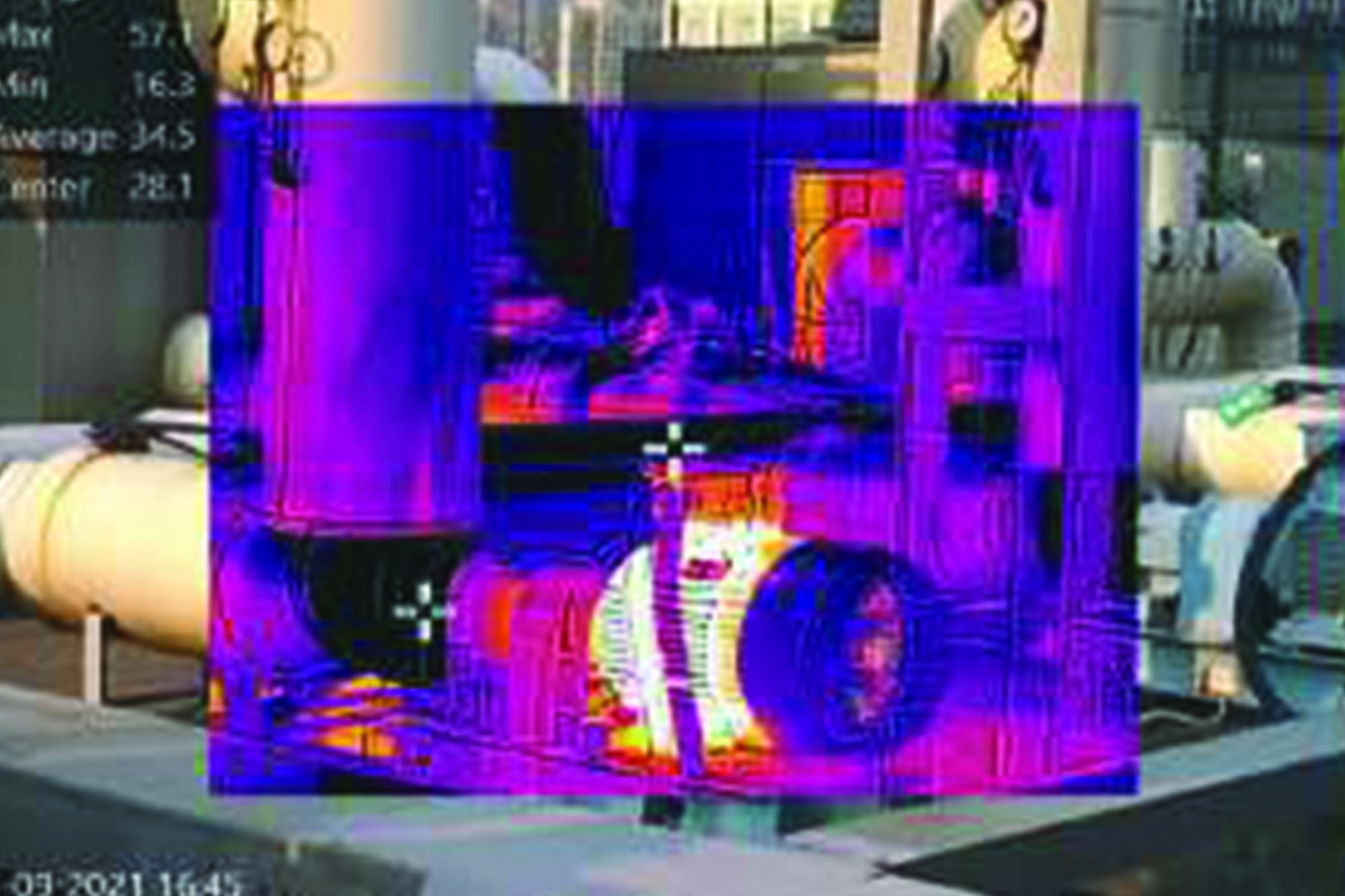

A thermal imaging camera can help crews and engineers establish a baseline for systems and equipment useful in future evaluations. Time-based, preventative maintenance gets expensive, and thermal cameras allow facilities to see the condition of equipment and schedule only the required maintenance and repairs.

Over time, thermography can offer insights into trends related to equipment’s lifecycle, declining performance, and the need for scheduled downtime for maintenance. Most failures occur very early in the life cycle or near the end, and thermal cameras are excellent tools for spotting issues in both phases.

By comparing the results of equipment and components under similar conditions, professionals can develop temperature profiles to detect anomalies easily. Additionally, with accurate temperature measurement, thermographers can assess the severity of a fault to schedule repairs rather than just reacting to failures.

Measurable sustainability: Detect energy losses such as cold bridges along roofs and walls, cold and heat influxes at doors and windows, and radiator recesses. Discover defective or missing insulation.Troubleshooting: Gain access, spot check, and evaluate equipment and components from angles you can’t reach and with insights the naked eye can’t assess.

Manufacturing

Like thermal imaging applications for facilities maintenance, manufacturing and process industries can use thermography to preventative and predictive maintenance, measure sustainability, and troubleshoot. There is good reason to lean on thermal imaging for these tasks. In a recent multi-year study conducted by the California Manufacturers and Technology Association in collaboration with CNA Financial Corporation, 6,154 thermography inspections were evaluated. Thermography inspections saved customers an estimated 52 million dollars, with an impressive ROI of $8,449 daily savings.

Thermal imaging also has several applications that are unique to manufacturing.

Condition monitoring: As scale and line effectiveness become vital, so do optimised sampling and monitoring of conditions. Thermal imaging makes this process more efficient and sustainable for any production line of any size.

Planned maintenance: Ensure minimal interruption to manufacturing operations by monitoring line and process equipment and scheduling downtime for maintenance instead of chasing problems as they occur. When you can see and measure more of your equipment and how it’s functioning, you can better plan your operations and maintenance.

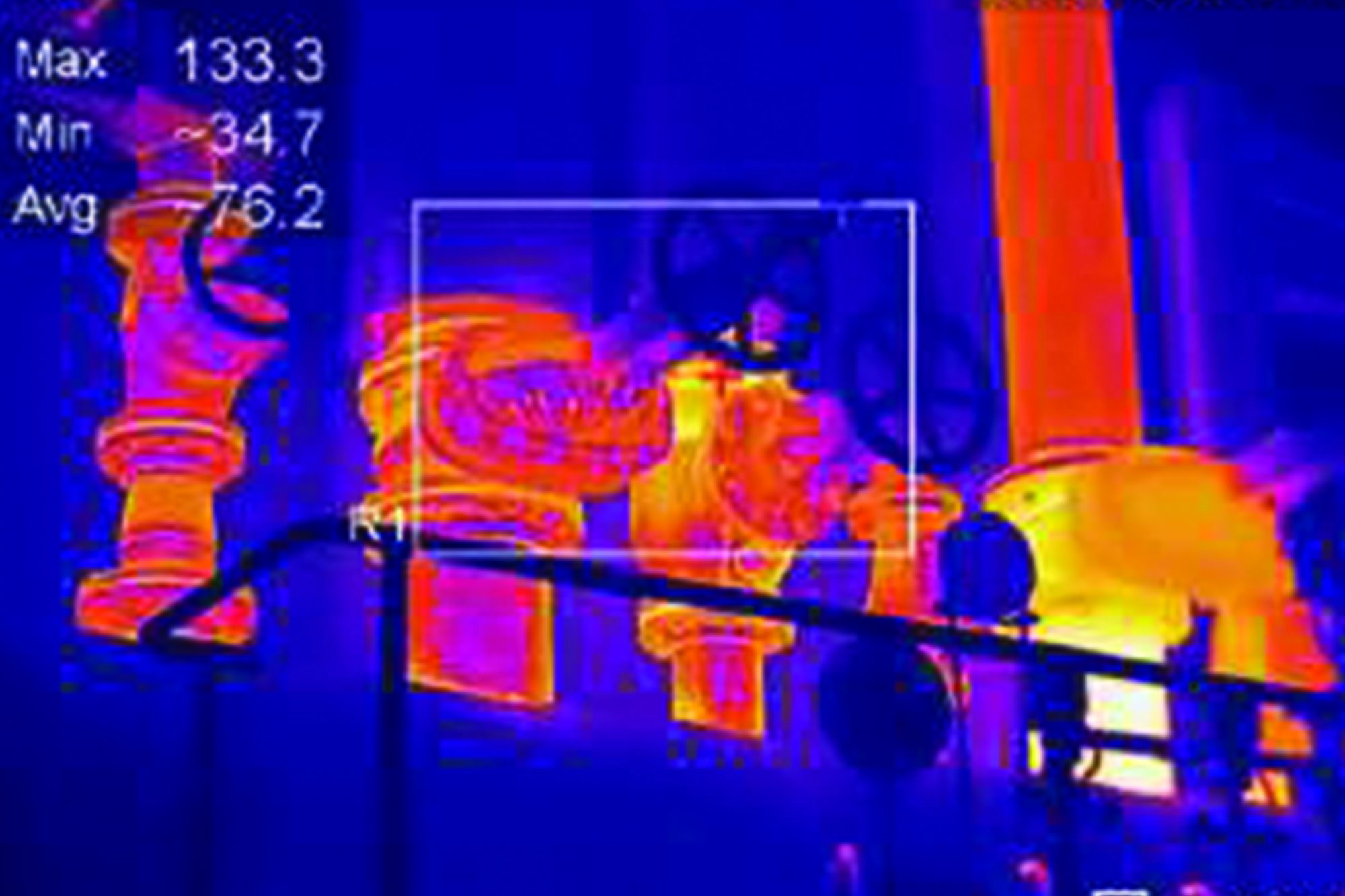

Oil and Gas

Oil and gas industries can and do benefit immensely from thermal imaging cameras. In fact, without thermal imaging, refinery production can lag or even come to a halt, and equipment and personnel safety are brought into question. For example, detection and maintenance are two of the most important jobs where thermal imaging cameras are used.

Gas and chemical detection: Many gases and chemical compounds are visible to the human eye. However, tracing and rectifying leaks of invisible volatile compounds early will aid regulatory compliance, maximise profitability and ensure safe working conditions.

Facilities and equipment maintenance: Refineries require optimised facilities maintenance. Critical vessels require monitoring reactors and the external shell. Processing facilities require perimeter protection from unauthorised persons and animals, often in inclement weather or at night. Thermal imaging cameras are the answer to all of these challenges.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.