OMRON launches ‘G9KA’ high-power PCB relay

By EPR Magazine Editorial July 2, 2021 6:40 pm IST

By EPR Magazine Editorial July 2, 2021 6:40 pm IST

Contributing to realisation of decarbonised society by improving energy efficiency through heat generation suppression.

OMRON’s electronic and mechanical component business division has announced the global launch of its high-power PCB relay – G9KA. This product improves the power generation efficiency of PV generation systems by minimising energy loss caused by the heat generated by power conditioners, power supply equipment, and related equipment used in solar power generation systems. The industry-leading (as of May 2021 according to OMRON’s research) ultra-low contact resistance of 0.2 mW (initial contact resistance value under the condition of 200A, 30 minutes) suppresses the heat generated by the relay and improves the power generation efficiency of solar power generation systems, thereby accelerating renewable energy deployment and contributing to the realisation of a decarbonised society.

In recent years, the effective use of limited energy resources has become a major social issue, and there is a need for highly efficient energy conversion in sustainable energy production. On the other hand, power generation facilities using renewable energy, such as solar power, generate energy loss due to the heat generated by the equipment during power generation, and the capacity and current of the facilities and equipment are increasing; therefore, countermeasures against heat generation have become an urgent issue.

One of the factors that can cause the equipment to generate heat is the relays mounted on the PC board inside the equipment. Relays are components used for executing ON/OFF control of the electric current flowing through the equipment when linked with the power system, and for safety shutoff in an emergency. Conventional high-power relays have a high contact resistance value, so energy loss due to heat generation has been an issue.

There were cases where heat dissipation mechanisms such as heatsinks and cooling fans had to be installed inside the equipment as a countermeasure against heat generation, and cases where the deterioration of the PC board due to the heat generated by the relay led to a decrease in the durable years of the equipment.

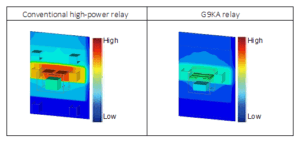

The G9KA can reduce the temperature rise of the relay by about 30 percent (As of November 2020, according to OMRON’s research, comparison of the temperature rise when 200A is energised with a relay with equivalent performance of G9KA) – compared with conventional high-power relays – by lowering the contact resistance to the industry-leading 0.2 mW. This product helps to reduce the size and weight of equipment by simplifying the heatsink and cooling fan that were installed as a countermeasure against heat generation. In addition, suppressing the heat generated by the relay leads to a reduction in the temperature rise of the PC board, thereby contributing to the longevity of the equipment.

OMRON will continue to contribute to the realisation of a decarbonised society through its customers’ products and services by creating advanced devices and modules based on the technologies it has cultivated over many years and providing them globally.

Main applications are in power conditioner for industrial solar power generation, EV quick charger, robot control equipment, storage batteries (UPS), and industrial air conditioner.

Key features of G9KAIndustry-leading ultra-low contact resistance (0.2mW) suppresses heat generation

Comparison of temperature rise results when 200A relay is energised (simulation).

Supporting high-capacity applications

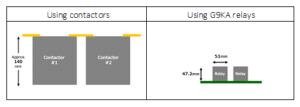

Capable of energising and de-energising 200A (800 VAC), this product can be used in equipment and applications where large current loads need to be cut off, and can also replace contactors that are primarily used for high-capacity power control applications. Compared to contactors with similar current capacity, the height of the component is reduced to about 1/3 (As of May 2021, according to OMRON’s research), which contributes to miniaturisation of the equipment and space saving.

Height comparison when components are mounted on the PC board.

For more information, please refer to this link

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.