Benefits of hot-dipped galvanised steel over pre-galvanised steel; a developer’s perspective

By EPR Magazine Editorial September 28, 2022 6:41 pm IST

By EPR Magazine Editorial September 28, 2022 6:41 pm IST

Preface

Steel is the most common material used in almost all products, i.e., from households to Industrial applications. The steel sector is a significant part of the economy; however, it has one considerable disadvantage – its high corrosion rate. Hence protection of steel structures and components is of great economic importance. In the Indian subcontinent, the corrosion rate is relatively high, considering hot and humid environmental conditions. Zinc is mainly used as an anti-corrosion agent from very early ages, i.e., from 200 BC, to obtain brass, an alloy of copper and zinc. It has an inherent natural capacity to protect steel against corrosion.

In 1742, a chemist called Melouin found that a zinc coating could be applied to iron by dipping it into molten zinc, laying the foundation for galvanising. In 1780, an Italian physicist, Luigi Galvani, observed that the contact between two dissimilar metals resulted in the flow of an electrical current. He worked in galvanisation, and the name of this physicist; process is named galvanisation. Subsequently, in 1836, a French civil engineer, inventor cum chemist named Stanislas Sorel patented a galvanisation method by cleaning steel and then coating it with zinc by dipping it into molten zinc. This was the beginning of modern hot-dip galvanising.

Benefits of Galvanisation

Hot-dip galvanising has been used for over 100 years to protect steel corrosion worldwide; however, many new materials and processes have evolved over the decades. Comparing all the use of hot-dipped galvanising remained most trusted based on their superb performance and to-date experience as users.

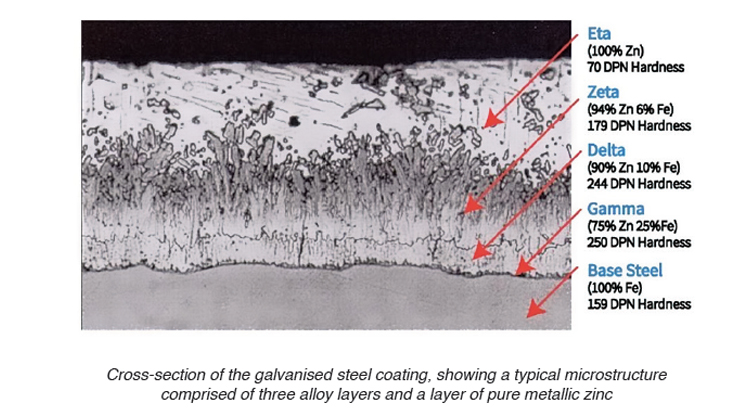

In the HDG process, the base material gets three-level protection.

Reasons for opting for hot-dipped galvanisation over pre-galvanisation from the developer’s perspective

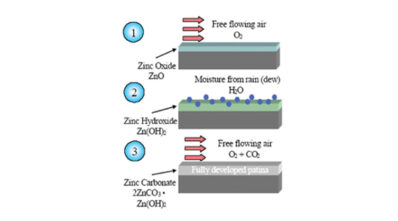

Corrosion protection

Galvanisation applies a protective zinc coating to steel or iron to prevent corrosion. There may be various other ways of corrosion protection; however, the galvanised coating is one of the most durable forms of corrosion protection. In an ideal condition, i.e., without any operation loads on the steel structure, i.e., if the galvanised steel is kept, with an average coating thickness of 85 microns, it will protect the base material for almost 100 years. It means the galvanisation is very durable.

Hot-dipped galvanising is a proven and well-established method. HDG members come with a service life guarantee; however, pre-galvanised steel suppliers do not provide a performance guarantee beyond 5 to 10 years. Scientific literature is present in the case of HDG stating the year-on-year degradation of the coating in various corrosive environments. In contrast, no such data is available for Pre-Gal material, and the asset’s life is at risk beyond ten years.

Maintenance

Hot-dipped galvanisation is almost maintenance-free. Once it is done, there is no requirement for reapplication or recoating. Hot-dipped galvanising is very much sustainable. In the case of pre-galvanised material, after some service life, the pre-galvanised material needs replacement and/or maintenance.

Solar project life-cycle

Indian solar developers are trying to increase the solar project life to 35-40 years instead of the present standard of 25 years, and as most of the upcoming solar projects in India will be at C3-C4 corrosion zones, it is important to design the BOP systems for 40-50 years as well.

Cost-effective aspects of galvanisation

Galvanisation is techno – economically cost-effective solution compared to a grit, blasted equivalent painting system. PU or similar painting systems must be applied in multiple layers over grit-blasted steel surfaces. Usually, the painting scheme shall have 275 to 325-micron thickness per manufacturer prescription.

However, this is not possible in the case of pre-galvanised steel members. The steel members, which are fabricated using pre-galvanised materials, are highly susceptible to corrosion. In the pre-galvanised sheet (or similar products) manufacturing process, a bare steel plate of thickness is passed through the galvanisation process. As a result, zinc coating is applied (of 20/30micron) only on the exposed surfaces. While fabricating the structural member to the required shape and size, it is subjected to welding, punching, drilling, and cutting, i.e., all activities involved in fabrication work expose and damage the existing pre-galvanised layer corrosion starts, and the life of the steel structure member comprises.

Abrasion impacts and shock resistance

Hot-dipped galvanisation provides superior abrasion resistance. In the hot-dip galvanisation process, a formed zinc coating is firmly bonded metallurgically to the steel surface. Due to its unique metallurgical bond, a galvanised coating is incredibly tough, offering exceptional performance for all abrasion and shocks.

An initial outer layer of galvanisation provides reliability by acting as a buffer zone, helping to absorb any initial shock, impacts, abrasions etc., to the galvanised coating and metal surface. Also, the underlying zinc-iron alloys are harder than steel itself and will further reduce any potential penetration of the coat ing or the exposure of bare steel. This means that a galvanised coating is highly shocked, wear, and tear-resistant, particularly suited to areas of high-frequency industrial application. A hot-dipped galvanising coating can also help prevent damage during construction, transport, erection, and other mechanical activities.

This type of protection is impossible in pre-galvanised steel as the galvanised thickness is very thin compared to HDG.

Protection for steel structures

Hot-dipped galvanising is a fast activity. Once the steel members are fabricated, it simply requires just a few minutes of immersion into the molten zinc tank post-cleaning. The molten zinc reaches all exposed surfaces and does provide complete protection.

However, such protection in such a short time is not possible in the case of pre-galvanised material, as the punched, drilled, and cut surfaces remain unprotected, or it needs special treatment in special case requirements.

Typically, in Pre-galvanised material, the claimed 80-micron thickness of galvanisation represents 40 microns on the inner face + 40 microns on the outer face of steel; however, in Hot-dipped galvanising, 80 microns is a coating thickness on each side.

Protective coating for steel used in renewable energy projects

In the renewable power sector, all the structures which are comprised of thin structural members and costs are worked out based on the weight of the structural members; in such cases, the owner or project developer leverages the benefit of steel weight from hot-dipped galvanised members, this tonnage benefit is not available in pre-gal structures. In a hot-dipped galvanised process, the steel are metallurgical. This bond is very strong; in some cases, the strength of this interface layer, i.e., zinc + steel, is stronger than bare steel. Hence it is possible to optimise the base material thickness. However, this advantage of weight reduction is not possible in pre-galvanised or PosMAC-like materials.

(This article has been authored by Shankar Sengupta, Head – Energy Engineering Group, Adani Corporate House, Ahmedabad)

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.