Advanced CNC machines and IoT integration propel K-Lite to new heights

By EPR Magazine Editorial February 24, 2024 11:30 pm IST

By EPR Magazine Editorial February 24, 2024 11:30 pm IST

The government has announced schemes to encourage the establishment of semiconductor manufacturing units.

The utility sector in India is undergoing a significant digital transformation driven by factors like the competitive environment, technological advancements, and government initiatives. Sharmila Kumbhat speaks with the EPR Magazine, sharing insights into the industry.

What are the key factors driving the digital transformation in the utilities sector?

Digital transformations have become the need of the hour for the utility sector. It has become extremely significant for utility companies if they are to move with the fast-changing times and be a step ahead of the competition. It is also essential to devise solutions to help the constantly changing environment. This can be achieved by modernising the infrastructure and continuously improving it.

Key business drivers pushing the utility market towards digital transformation include the competitive environment. For instance, electric utility companies are leveraging smart meters for two-way communication, reducing human intervention such as call centres. Implementing business intelligence with analytics reporting solutions facilitates informed decision-making. Additionally, the adoption of smart grid technology, integrating smart poles to meet the requirements of other utilities and local administration, and deploying intelligent devices in the grid and smart homes are significant initiatives driving this transformation.

Water and wastewater utility companies are looking towards deploying geospatial information systems (GIS) to increase efficiency during their supply chain’s sampling, routing, and analysing phases. The popularity and the potential of social media with which consumers are changing how they buy utility products. This allows utility companies to add new value services and social networking tools to their websites.

Utility companies are forced to look towards better asset management and seamlessly integrated systems so that real-time information on assets is always available. This applies to both energy and water utility companies. Lastly, since most utility companies are using older systems built on outdated platforms and technologies, the problems of lack of support and high maintenance costs can be addressed using newer technologies. This clearly explains why digital transformations have also become the need of the hour for the utility sector.

How has the lighting industry evolved with digitalisation and government support?

The digital transformation in the power sector drove the lighting industry to adopt LED technology to the maximum extent and has wonderfully changed the power consumption pattern due to lighting, upside down. The concept of smart cities, the introduction of smart poles, and the availability of many digital devices, including IoT, have simplified the control systems.

The introduction of LED as a source for lighting has almost eliminated conventional sources such as incandescent bulbs, FTL / MV / SV/ MH lamps, etc., and the lighting industry has taken a full turn and converted all their luminaires into LED luminaires. Even though we had a very strong manufacturing base for conventional light sources, we needed to equip ourselves to meet the demand for LED chips during the changeover period. With the open market scenario, importing LED chips from China and other countries was much cheaper. The government has therefore announced schemes to encourage the establishment of semiconductor manufacturing units since LED luminaires have come to stay, and the demand is increasing multifold times. It is expected that with incentives and encouragement from the government, the semiconductors and various control devices for optimal utilisation of power and improvement of system efficiency will be manufactured locally.

K-Lite, on its part, wanted to create the infrastructure for LED assembly and allied works and testing facilities. Under M-SIPS ( Modified Special Incentive scheme), Deity approved a 10 cr project for us with a 25 percent incentive to procure machinery and create allied infrastructure.

What strategies has your company applied to compete in the evolving market?

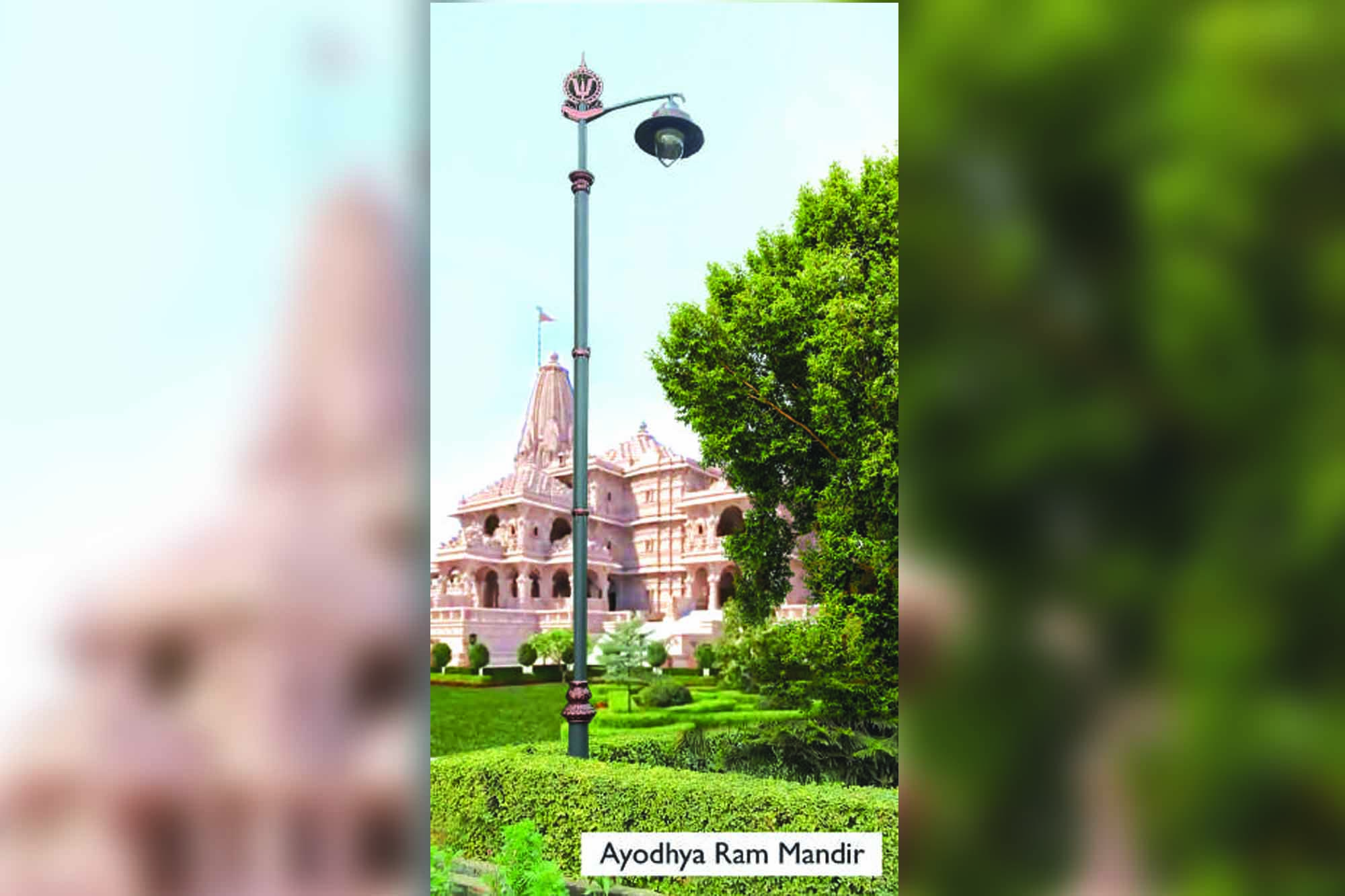

The digital transformation in the machine manufacturing sector came as a boon, and we installed state-of-the-art CNC machines and robots in assembly and welding systems. The workmanship and quality came to the level of excellence, and cost was optimised. This gave us a competitive edge to improve our sales with stiff competition, especially from Chinese-made luminaires. With the availability of suitable sensors, tunable LEDs, and many Internet of Things (IoT) accessories, we were able to meet challenging needs such as the creation of mood lighting, etc., and also the introduction of smart poles with multiple functions, including traffic control and interconnected city controls.

Spokesperson: Sharmila Kumbhat, Director, K-Lite Industries

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.