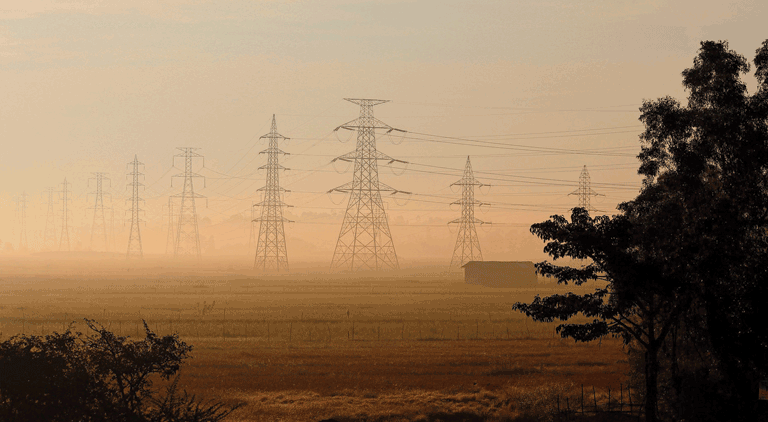

Emergency Restoration System: A quick solution to restoring critical transmission lines

By EPR Magazine Editorial April 29, 2020 10:04 pm IST

By EPR Magazine Editorial April 29, 2020 10:04 pm IST

Emergency Restoration System towers are a rapid response system to power outages and failures. Industry leaders discuss the drivers of market growth and how challenges faced by the ERS tower business can be effectively overcome.

An Emergency Restoration System (ERS) is a temporary bypass line solution used for restoring or reconductoring a transmission line in a short span of time. These temporary bypass lines are installed very quickly as they consist of modular tower sections that are capable of rapid installation without the use of any heavy machinery. The use of an articulated gimbal permits installation without the need to level the ground and thereby permits fast restoration. It has also been helpful where construction of elevated roadways and railway lines gets obstructed when they pass underneath an existing transmission line. In such cases, the height of existing towers can be increased without shutdown as the ERS tower keeps the line operational. Similarly, reconductoring can be done without outages.

Factors driving growth of ERS tower business

ERS towers display their significance during emergencies and disasters. Nowadays, global warming has heavily affected the climatic condition of India and the past 10-15 years’ data is evidence that the frequency of wind storms, rain storms, heavy floods, and earthquakes has increased. Apart from this, transmission line economics have changed, resulting in more efficient towers than in the past. These are the factors driving the ERS business as a very important tool in disaster management.

“There is a decent rate of acquisition of ERS by many power utilities so far; however, many government and private power players are still showing a passive attitude towards its acquirement into their fleet with the notion of letting some big damage happen first and then taking action. Such lack of proactive preparation and passive approach against disaster management concepts is hindering the growth of ERS solutions in the Indian power network field,” says Niraj Sarang, General Manager – ERS Division, Madhav Engineers Pvt. Ltd.

The key to being able to respond quickly when there are service interruptions due to damaged structures is to have the components of the ERS already nearby and available. Orders are therefore typically made in advance, either as single large contracts or in some step-by-step buying process to build up inventory.

Harish Agarwal, CEO, Supreme & Co. tells us, “Supreme has done a unique business model innovation by providing a full-service model in place of outright sale. We have a dedicated team which has acquired problem-solving expertise over the last three years, as they are constantly engaged in meeting all kinds of challenges and have done some restorations which have been global landmarks. Even the prestigious T&D World Magazine of the US has covered one of our projects and it is also being submitted in IEEE Conferences. Typically, when a customer buys outright, he buys a kind of one-size-fit-all software which will help tweak a tailor-made solution within a narrow bandwidth of options, whereas the expertise built by us covers a very wide array of tailor-made solutions.” Application of ERS is not limited only to calamitous events that damage line sections. Sometimes there is a need to reroute an existing line for a brief period to accommodate a construction project or to allow continued power flow while a line is being upgraded in some way.

He adds, “The unique feature of Supreme ERS structures is that they are made of high-strength steel. The fully standardised fabrication process of high-strength steel has made it an economical, functionally reliable, and structurally stable option. The savings due to reduced outage time far outweighs the cost of such ERS, which is now substantially reduced with the use of steel. The entire design is made in such a way that the whole structure can be erected in few hours. Sections are made modular in order to ease transportation as the site may be very remote to carry the structure. There is no need for any civil foundation. The tower is entirely supported using guy wires. Hence, it is essential that all the guy wires are properly anchored to the soil. We have designed anchors to suit all kinds of soil. This negates the O&M, training and storage cost that incur on the customer in case they own the system. Currently, it takes 5-6 days to transport our structures to the site and begin erection work. Hence, we are planning on setting up storage units across India, which will enable us to start line restoration immediately. We are discussing with major power corporations for Supreme to act as an electrical contractor for providing the ERS solution to them.”

Overcoming hurdles in the ERS tower business

The energy sector faces significant challenges as a result of ageing infrastructure, including supply, security and reliability, and resiliency issues in terms of severe weather events. All of these challenges pose a threat to public safety and the national economy. Ageing energy generation and T&D infrastructure turn out to be one of the biggest obstacles faced by utilities in developed and developing countries. It has a huge impact on their ability to provide a reliable, cost-effective, and “future-proof” provision for end users. Many countries are facing huge costs associated with electricity disruptions and customer minutes lost (CML). To avoid the cost of catastrophic failure caused by ageing assets, maintenance should be prioritised.

Niraj Sarang, General Manager – ERS Division, Madhav Engineers Pvt. Ltd.

Although the benefits from utilising ERS have been encashed by sellers in several states, ERS is yet to reach all utilities and end users.

Harish Agarwal, CEO, Supreme & Co.

The fully standardised fabrication process of high-strength steel has made it an economical, functionally reliable, and structurally stable option. The savings due to reduced outage time far outweighs the cost of such ERS, which is now substantially reduced with the use of steel.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.