Improving functionalities of capacitors with new designs and technologies

By EPR Magazine Editorial April 30, 2020 4:40 pm IST

By EPR Magazine Editorial April 30, 2020 4:40 pm IST

Capacitors are one of the most ubiquitous passive electronic components, and latest research and development in this field is revolutionising the capacitor market.

Capacitors play an important role in the design and manufacture of filters, amplifiers, power supplies and other circuits. Among the passive electronic components, capacitors are one of the most commonly used. Recent government projects and initiatives and industry innovations are helping this market grow at an unprecedented rate. We look in greater detail at the driving factors of the market growth of capacitors and the new technologies that are being introduced in the sector.

Use of capacitors in power supply

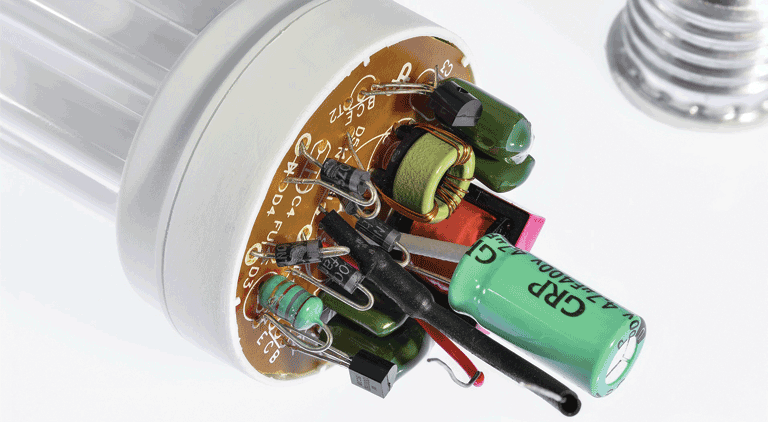

Capacitors are used in the supply of power to smooth or filter the pulsating DC output after rectification so that an almost constant DC voltage is supplied to the load. The rectifiers’ pulsating output has an average DC value and an AC portion which is called ripple voltage. Filter capacitors reduce the amount of ripple voltage to a level that is acceptable. Resistors and inductors can be combined with the capacitors to form filter networks.

Narendra Kumar Vasista, Director and CEO, Inelec Engineers India Pvt. Ltd. tells us, “The primary energy saving is through power factor correction — reactive power compensation (RPC). RPC is done by adding or removing capacitors to the circuit. When power factor is improved, the current in the circuit gets reduced and thereby losses (I2R). Power transmission has to improve with lesser losses for improved power factor (PF), which requires use of more capacitors at the substations and receiving stations.”

Need for design improvements to increase energy storage capacity

In terms of the challenges that companies in the capacitor segment face, Vasista informs, “The design of ratings for capacitors (in kVAr) should mainly be accurate. If not, it will result in resonance due to which the entire circuit will blow out.” Presently, the design of power capacitors is limited to Metallised Polypropylene (MPP) or Hazy Polypropylene with separate Aluminium Foil (APP). The first type is used in low-voltage and the latter in medium- and high-voltage applications.

EPCOS India Pvt Ltd, a TDK Group company and one of the leading electronics companies in India, has a network of design and manufacturing locations for film capacitors across the country. Through its full compliance with the BIS mandate, EPCOS India has underscored its reputation of being a leader in the Indian electronic components market by not only carrying the ISI marking, but also by ensuring that its ISI-marked capacitors are already available for customers. In fact, some EPCOS PFC capacitors are already BIS-compliant and have been carrying the ISI marking for the past several years.“We appreciate this policy initiative by the government of India and efforts undertaken by the BIS toward creating a safe environment for use of electrical and electronic items. The BIS mandate ensures that there is a level playing field with respect to the specifications with which a product is produced,” said N Balakrishnan, MD, EPCOS India.

Market drivers of capacitors

The rising demand for renewable energy and the government’s “Make in India” initiative are creating a positive impact on the capacitor market. The Green Energy Corridor (GEC) project, which aims at integrating electricity produced from renewable sources such as solar and wind with conventional power stations in the national grid, is also another factor contributing to the increased demand for power capacitors. With more manufacturers taking up local production of capacitors, newer technologies are coming into the sector that are further keeping this market in the spotlight.

Supercapacitors (SCs) have been a hot topic in the power sector in recent years, and research and development of SCs is growing. SCs are high-performance energy storage devices whose performance can be determined in terms of the electrochemical properties defined through a combination between the electrode and the electrolyte materials. Similarly, their charge storage capacities can be greatly impacted by proper material selection. Efforts have been put to make them more efficient with existing energy storage options like rechargeable batteries.

Vasista shares, “Supercapacitors are basically used in electronic circuits to offer stability for power supply to gadgets, and extending the same to higher capacity and applications other than energy storage is not economical.”

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.