IoTx prevented transformer shutdown and probable explosion saving huge revenue loss

By EPR Magazine Editorial March 3, 2020 5:39 pm IST

By EPR Magazine Editorial March 3, 2020 5:39 pm IST

Transformer oil is essential in the overall functioning of a transformer. Moreover, an inadequate level or leakage of transformer oil could lead to a major mishap that can affect assets as well as human safety. This became a reality in one of The Motwane Manufacturing Company Pvt. Ltd.’s customer’s case with a 315 kVA transformer installed at their manufacturing facility. Motwane’s IoTx, a digital transformer monitoring system, helped them identify an oil leakage in the conservator that might have led to the transformer shutdown and probable explosion affecting human safety and huge revenue loss, had it gone undetected. IoTx monitors critical transformer parameters on a real-time basis and gives alarm/notification in case of any anomalies.

This 315 kVA transformer has an IoTx installed. In the absence of IoTx, it could have been impossible to detect an oil leakage, unless a physical inspection was carried out. It would also have been difficult to detect the exact location of leakage by correlating loading conditions and oil level.

Root cause and issue identified by IoTx (digital transformer monitoring unit): Oil leakage from transformer

Earlier when this issue was raised on 4th December 2019, the quantity of oil filled in the conservator was recorded at 60 percent of the conservator’s total oil level.

⦁ First issue of low oil level in the conservator was observed on 11th December 2019 by IoTx.

⦁ Since then, IoTx monitored the oil level in conservator every 5 minutes, until it was refilled and leakage issue was resolved on 23rd January 2020.

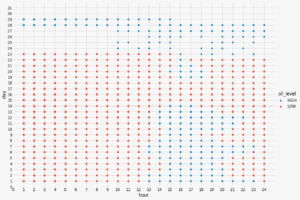

Transformer oil level daily instance report

The above diagram shows each hour of oil level status for January.

The oil level was below the set limit, but due to contraction and expansion of the oil, this level used to rise above the set limit for a specific amount of time, majorly in the daytime when the loading on the transformer was more and the ambient temperature was high.

⦁ It was found that the oil level was below the set level every day from 9 PM to 1 PM; this might be because of less loading on the transformer and low ambient temperature.

⦁ It was also found that the oil level was above the set level every day from 1 PM to 9 PM; this might be because of more loading on the transformer and high ambient temperature.

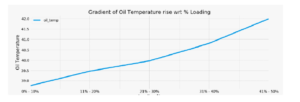

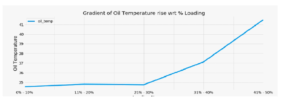

By virtue of streaming data available through IoTx, Motwane plotted a graph of the gradient of oil temperature rise with respect to percent loading. The purpose of the below graph is to establish a correlation between the loading of the transformer and the rise in oil temperature.

Transformer oil temperature gradient report for November 2019

Transformer oil temperature gradient report for January 2020

The above two graphs depicted that the gradient of oil temperature rise with respect to percent loading was nearly about the same, i.e., 42℃ for 41-50 percent. This signified that the oil level in the transformer tank was good. Hence, it was confirmed that the oil leakage issue was only at the conservator of the transformer.

The transformer was saved from the following possible anomalies:

⦁ The oil level in the transformer tank could have decreased, which might have ultimately resulted in heating the transformer winding and transformer oil.

⦁ Air bubbles and impurities in oil could have increased, which might have decreased the oil quality and an insulation breakdown.

⦁ The transformer winding might have burned out due to the high winding temperature, which could have been a huge monitory loss.

⦁ Also, downtime could lead to revenue loss.

The transformer and revenue loss was ultimately saved by the virtue of IoTx

⦁ Beyond repair: Transformer price/replacement cost (approximate): ₹2,50,000-₹2,80,000

⦁ Repairing cost/winding replacement/oil replacement cost (approximate): ₹80,000-₹1,20,000

⦁ Saved 30 percent of transformer oil

⦁ Revenue loss due to transformer failure: Per day production loss (varies case to case basis)

Source:- https://bit.ly/2Ikh1S2

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.