Oiling the electrical outages

By EPR Magazine Editorial December 11, 2018 11:41 am IST

By EPR Magazine Editorial December 11, 2018 11:41 am IST

Assessment of plant status and estimating the plant life can easily be done by oil condition monitoring. Oil testing done on a regular basis can determine oil deterioration at an early stage.

Heart of power system

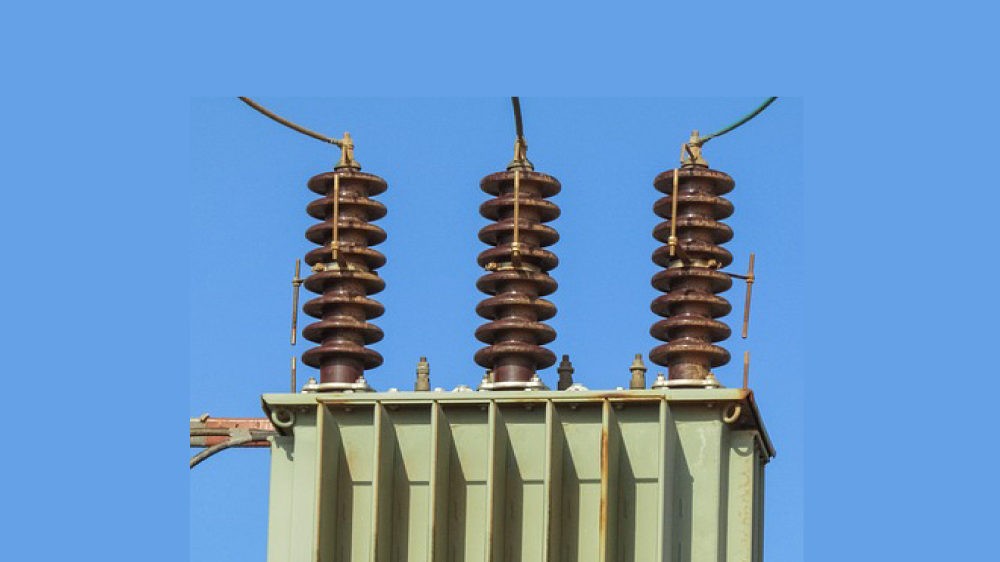

Transformer is a static asset, and I commonly relate it using the human analogy, with it being the ‘heart’ of the power system; and here the liquid insulation (oil) is the ‘blood’ running through this heart. Simply put, just as we regularly get our blood tested and analysed, not just to see if the blood itself is acceptable; but also to give a fair understanding of the condition of our body’s organisation; such is the relationship of transformer and its oil.

Key factor to be considered

I would further break it down to three key aspects that one needs to understand. Firstly, condition assessment; what we, in the industry understand as an ‘incipient fault’; i.e. the birth of fault, which is not evident, but will soon be; oil analysis such as DGA, Furan, MiO etc. possess the ability to detect and trace in the slightest of its forms. Anything that happens inside the transformer’s body will be reflected in the oil analysis. Hence, it gives us a nearly real-time condition diagnostic for transformer assets. On further assessments of these fault, NDL diagnose the RCA and associated element causing such occurrence with highest accuracy and reliability.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.