RTV-Coated & Polymer Insulator: FAKES VS FACTS

By EPR Magazine Editorial November 14, 2022 4:53 pm IST

By EPR Magazine Editorial November 14, 2022 4:53 pm IST

The article briefly discusses the FAKES Vs FACTS on eliminating Power Lines and substations’ cold maintenance outages caused by Glass, Ceramic, Polymeric, and RTV-Coated Polluted Insulators.

FAKES Vs. FACTS

Everyone involved in power utilities experiences leakage currents, short circuits, and current interruptions on their infrastructure, frequently caused by polluted insulators.

Outdoor insulators are subject to surface dirt deposits in all operational areas. Most encountered contaminants have little effect on insulator performance if the surface is dry. The pollutants gradually build up on the insulators but do not decrease the insulation strength when the insulators are dry.

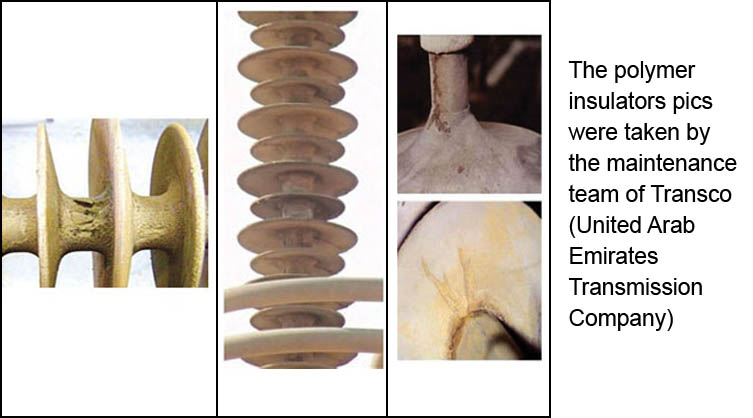

The polluted insulators become wet, and a conductive layer forms on the contaminated insulator surface in coastal and inland T&D power lines and substations installed in climatic areas subject to dry weather followed by fog, mist, light rain, and in the proximity of contaminants sources, e.g., coal, cement factories, industrial/ agricultural dust, and cooling tower effluents.

FAKE: Composite-Polymer and RTV silicone-coated insulators are maintenance-free and sold, emphasising hydrophobicity as the main feature and claiming that the hydrophobic feature is a crucial factor in limiting leakage currents. Moreover, preventive maintenance is often emphasised as being minimal and ultimately unnecessary. Because contaminants settle in dry periods, the pollutant layer covers the hydrophobicity feature; therefore, the paramount quality of being hydrophobic is voided and a conductive layer forms on the contaminated insulator surface, initiating a leakage current.

RTV coatings are designed to replace silicone grease and water washing and, it is claimed, to eliminate the maintenance cost.

As an example, the Dow Corning RTV coating XIAMETER® ECE-3650 Sylgard HVIC is sold, as stated in their documents, outlining that the main benefits and features are:

• Flashover’s protection, and long-term hydrophobicity, imparts arc resistance and hydrophobicity

• Exhibits a unique ability to recover water repellency after contaminants are deposited on its surface. Minimizes surface damage from electrical activity during extreme weather events.

As is the case with polymeric insulators installed in areas subjected to dry weather followed by fog, mist, and light rain, as well as near contaminant sources, the RTVcoated insulators become wet, and a conductive layer forms on the RTVcoated but polluted insulator surface.

Within a variable length period (depending on the climatic conditions), RTV coatings degrade with the coating peeling off, forcing a power outage to resolve issues with cold cleaning and washing procedures.

400 kV Power Transformer – RTV Coated and Polluted Insulators (Location: Ras Girtas Power Co., Ras Laffan C IWPP, Qatar).

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.