Applications of Rishabh IED in FRTU Panel

By EPR Magazine Editorial March 4, 2020 12:05 pm IST

By EPR Magazine Editorial March 4, 2020 12:05 pm IST

The paper describes the various functions that Intelligent Electronic Device (IED) plays in today’s power networks. They are used for protection purposes, power quality analysis, network monitoring, and energy metering. They have to be equipped with communication protocols that are used in substation automation as per IEC 61850 along with Modbus RS 485 and TCP/IP. So we mainly focus on the application of Rishabh IEDs in Feeder Remote Terminal Unit (FRTU) Panel which is installed along with Ring Main Unit.

Introduction

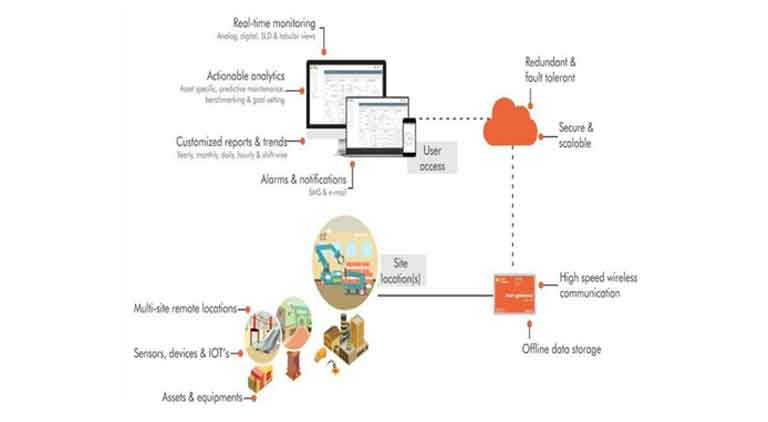

Electric energy is a commodity that like any other is bought under a contract between a customer and utility. The customer expects a high quality power at a negotiable price. Growing customer expectations and new regulations force utilities to manage their grids in an intelligent way. To do that, the information has to be collected from the grid and processed in real time in order to enable automatic optimisation of the power delivery efficiency for demand and supply side management. The monitoring system consists of transducers, sensors and Intelligent Electronic Devices (IEDs) located throughout the distribution system that gather the data, process it as necessary and transmit to control centres.

IEDs have been deployed extensively in power automation systems recently, and the shift from RTUs to IEDs is evident due to the integration and long-distance communication features of the IEDs. This technical article briefly explains the IED advanced functionality to present view of automation in power systems. In addition, the IED handles additional features like self and external circuit monitoring, real-time synchronisation of the event monitoring, local and substation data access, and an entire range of software tools for commissioning, testing, event reporting, and fault analysis.

Metering and power quality analysis

Metering capabilities of the IEDs became acceptable to the power utilities quickly, and major cost saving was achieved by combining the non-revenue metering function into the IEDs. It may be noted that the primary CTs and VTs for protection purposes may not be accurate enough for normal current measurement for revenue metering. The normal metering functions include measuring the voltage and current root mean square (RMS) values and the real and reactive power. Hence, for revenue metering, we need a highly precise measured value with high accuracy of 0.2s-0.1 class current transformer.

Load profiling is another metering activity that can be achieved using Rishabh Load Manager LM1360 IEDs, where the power factor profile, ampere demand, long-term RMS voltage value, Harmonics, THD and Phase sequence can be monitored and used for load profiling along with data logging facility. Rishabh’s Power Quality Analyzer eliminates the digital recorders because waveform recording during a voltage dip, voltage swells, in rush current measurement, and distorted waveform can be performed by the IEDs, whereas the electro-mechanical relays as well as normal energy meters did not have such capability. Event reporting can be easily done by RISH PQA IEDs eliminating sequence of events (SOE) recorders.

Ring Main Unit (RMU)

Ring Main Unit is a compact, sealed for life metal-enclosed switchgear widely used in urban power distribution network. A Ring Main Unit includes a combination of one or more Load Break Switch (LBS) cum earth switch as incoming and outgoing feeder and vacuum circuit breaker with associate disconnect and earth switch for load feeders. Depending on the requirement, RMU is available in different voltage ratings (mainly in medium-voltage level) and are suitable for both indoor and outdoor installation.

The RMU is an innovative solution that makes it easier to manage the numerous challenges of electrical distribution. RMU is an all-in-one solution and is a safe, easy-to-install and maintenance-free switchgear helping the utilities improve reliability and uptime of the network and reduce the operational costs.

Feature-rich compact designs: Ring Main Unit is an SF6 insulated compact switchgear equipped with SF6 switch disconnector and vacuum circuit breaker. Its compact design requires least possible space to install and operate.

Time and cost savings: RMU is a complete switchgear and is easy to install, thereby saving installation and commissioning time. Independent of climate and resistant to environmental conditions, the operation and maintenance costs of these units are also low.

Smart capabilities: When fitted with Intelligent Electronic Devices and communication capabilities, the RMU is easy to integrate with distribution management system and in building a smart grid solution.

In the modern urban power distribution system, Ring Main Unit is widely used across India and around the world to efficiently meet the growing needs of reliable energy. It is one solution with comprehensive capabilities.

Feeder Remote Terminal Unit (FRTU) and Rishabh IED

The FRTU system will monitor all the substation equipment and check all the parameters of incoming and outgoing feeders in real time. It also monitors the status of circuit breakers, relays, isolators, etc. that are prevalent in any substation. The overall system needs planning, execution, forecasting, implementation and maintenance, etc. Energy supply is to be balanced with the load demand continuously under normal and abnormal situations such as loss of generation, equipment failures, line faults, peak loads, load shedding, etc. in order to maintain system stability, reliability, and availability. The application of FRTU leads to automatic data logging, substation level control, energy management, load forecasting, etc. Eventually, it will lead to substation automation.

FRTU functions

In acquiring analogue values from multifunction transducers or alternatively through direct signal modules and the status inputs of devices from the substation, processing and transmitting to master stations, two PT100 sensor inputs shall be taken in FRTU directly or through transducers to measure temperatures for distribution transformers connected to the RMU.

Use of MODBUS over RS485 interface protocol to communicate with the MFTs and FRTU shall be capable of acquiring analog values through transducers having output as 4-20 mA, 0-10 mA, 0-+10 mA etc, using analogue input modules.

Parts of FRTUMFTs installed in RMU

RTU shall also take 4-20 mA as analogue inputs to acquire DC battery voltage, etc.

Control outputs : The FRTU shall provide the capability for a master station to select and change the state of digital output points. These control outputs shall be galvanically isolated and used to control power system devices such as circuit breakers, isolators, relays and other two-state devices, which shall be supported by the RTU. Switching voltage is 24 V DC. Each control output shall consist of one set of potential free no contact. The output contacts shall be rated for at least 3 Amp continuous at 24 VDC.

Power supply: The FRTU will be powered from a 24 V DC power supply system. The RTU shall not place additional ground on the input power source. The battery and battery charger should be capable of performing all FRTU required operation and provide reliable aux. supply to modem, MFT and DC transducers, etc.

FRTU requirement: Nominal voltage of 24 VDC with variation between 20.4 and 28.8 Vdc (+20 percent/-15 percent.)

AC input supply: The nominal input frequency is 50 Hz, which may vary from 47.5-52.5Hz. The input voltage shall be single phase (nominal 240V) varying from 190V to 265V for power supply for DCPS.

DC output required: The module shall be capable of operating in “Auto Float-cum-Boost Charge” mode depending on the condition of the battery sets being sensed by the control unit.

The float voltage shall be continuously adjustable and preset-able at any value in the range of 24 to 28V (for 24V) either at the module or may be set from the common controller

Transducer

All transducers use a 24 VDC auxiliary power supply as provided for the FRTU. All transducers shall have a maximum power consumption of 10 watts. Transducer shall be din rail or wall/plate mounted. Each FRTU shall be provided with two DC Voltage Transducers for monitoring DC battery voltage for RMU and FRTU battery. The input, output and auxiliary circuits shall be isolated from each other and earth-ground. The transducer output shall be underground and shall have short circuit and open circuit protection. The transducers shall comply with the IEC 60688, without damage with the transducer.

DC transducer: The DC transducer (DCT) is of two types:

Voltage current: The DC transducer are required to measure battery charger current and voltage shall be suitable for 20 percent continuous overload and able to withstand 20 times the normal current rating for a period of one second. The DCT shall be able to accept the input up to 120 percent of the nominal voltage. The DCT shall have low VA burden. Output of the device shall preferably be 4-20 mA with an accuracy of 0.5.

Multifunction transducers (MFT)

It requires multifunction transducers for acquiring the real-time analogue inputs through three-phase three wire.

For more information:

Ganesh P. Tupe,Executive Sales Engineer,Rishabh Instruments Pvt. Ltd.

www.rishabh.co.in

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.